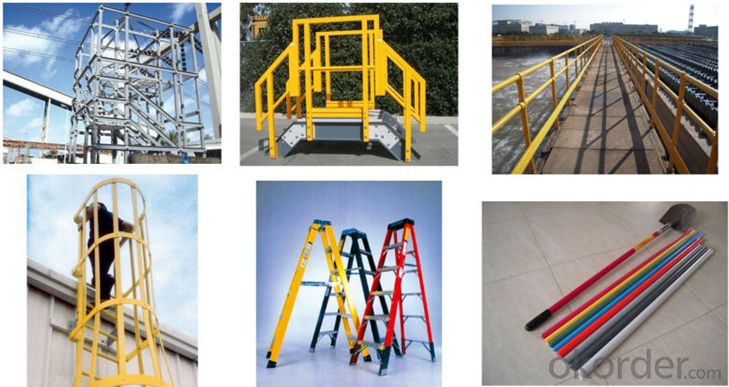

Fiberglass Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

fiberglass mesh grating

1.meet ASTM E-84 AND ISO9001

2.anti-corrosion floor

3.anti-conductive

4.walkway,platform,trench cove

fiberglass mesh grating

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

- Q:Can FRP pultrusion profiles be used in the construction industry?

- Indeed, the construction industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous benefits that make them appropriate for diverse construction applications. To begin with, FRP pultrusion profiles possess exceptional strength while remaining lightweight. Consequently, they are an excellent choice for construction projects as they provide a high strength-to-weight ratio. This reduces the overall weight of the structure while preserving its structural integrity. This advantage is particularly valuable for applications like bridges, walkways, and platforms. Furthermore, FRP pultrusion profiles exhibit a high level of resistance to corrosion. Unlike conventional construction materials such as steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. Consequently, FRP profiles are ideal for outdoor or marine applications where corrosion can be a concern, such as seawalls, docks, or offshore structures. In addition, FRP pultrusion profiles possess excellent electrical and thermal insulation properties. This makes them suitable for applications where minimizing electrical conductivity is necessary, such as electrical enclosures or cable trays. Moreover, FRP profiles have low thermal conductivity, which enhances energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They boast a long service life and do not necessitate regular painting, sealing, or treatment like traditional materials. Consequently, significant cost savings can be achieved throughout the life cycle of a construction project. Lastly, FRP pultrusion profiles can be customized to meet specific strength, stiffness, and dimensional requirements. They can be produced in various shapes, sizes, and colors, allowing for flexibility in design. This versatility renders FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. To summarize, FRP pultrusion profiles are a viable choice for the construction industry due to their lightweight nature, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q:Are FRP pultrusion profiles resistant to weathering?

- FRP pultrusion profiles exhibit exceptional resistance to weathering, thanks to the pultrusion process. This process generates a robust, long-lasting, and non-corrosive material that inherently withstands diverse weather conditions. Comprised of a fusion of fiberglass reinforcements and a thermosetting resin matrix, FRP profiles boast a unique composition that delivers outstanding protection against UV radiation, moisture, chemicals, and temperature changes. Consequently, these profiles prove ideal for outdoor applications. Extensive testing has verified that FRP pultrusion profiles retain their structural integrity and physical properties even after prolonged exposure to harsh weather conditions. Unlike conventional materials such as wood or metal, they do not degrade, warp, or crack due to sunlight, rain, snow, or extreme temperatures. The exceptional weather resistance of FRP pultrusion profiles enables their utilization across a broad range of industries, including construction, infrastructure, marine, and transportation. Moreover, these profiles exhibit a low thermal expansion and contraction rate, ensuring dimensional stability in fluctuating weather conditions. This quality prevents warping or distortion over time, making FRP pultrusion profiles an excellent choice for long-term outdoor use. To summarize, FRP pultrusion profiles excel in weather resistance and offer enduring durability in various outdoor environments. Their capacity to endure UV radiation, moisture, chemicals, and temperature fluctuations makes them a dependable and cost-effective solution for diverse applications.

- Q:Do FRP pultrusion profiles require regular maintenance?

- No, FRP pultrusion profiles do not require regular maintenance. They are highly durable and resistant to corrosion, rot, and other environmental factors. This makes them ideal for applications requiring low maintenance and long-term reliability.

- Q:How do FRP pultrusion profiles perform in seismic zones?

- FRP pultrusion profiles are highly suitable for use in seismic zones due to their inherent properties and characteristics. One of the key advantages of FRP pultrusions is their excellent strength-to-weight ratio, which allows them to efficiently withstand seismic forces without adding significant weight to the structure. In seismic zones, buildings and structures are subjected to intense ground motions during an earthquake. FRP pultrusion profiles possess high stiffness and strength, enabling them to effectively resist the lateral forces generated by seismic activity. These profiles have a high modulus of elasticity, which allows them to maintain their shape and structural integrity even under extreme seismic loads. Moreover, FRP pultrusions exhibit excellent corrosion resistance, making them highly durable in seismic zones. Unlike traditional materials such as steel or concrete, FRP profiles do not corrode when exposed to moisture, chemicals, or salts, which are commonly found in seismic regions. This corrosion resistance ensures the long-term performance and structural integrity of FRP pultrusion profiles, even in harsh environmental conditions. Another advantage of FRP pultrusions in seismic zones is their flexibility and ability to dampen vibrations. During an earthquake, the ground motions cause structures to vibrate. The inherent damping properties of FRP materials help absorb and dissipate these vibrations, reducing the potential for structural damage. Additionally, FRP pultrusion profiles can be designed and manufactured to meet specific seismic requirements and codes. They can be reinforced with additional layers or designed with specific geometries to enhance their seismic performance, ensuring that they meet the necessary safety standards in seismic zones. Overall, FRP pultrusion profiles offer numerous benefits for use in seismic zones. Their high strength-to-weight ratio, corrosion resistance, damping properties, and design flexibility make them an excellent choice for constructing seismic-resistant structures while ensuring durability and safety.

- Q:Is the test standard for FRP pultruded profiles and FRP gratings the same?

- Pultruded section is produced by extrusion automatic production line. Glass fiber reinforced plastic grille is produced by mould and hand laying process. If it is a pultrusion grille, it is also made of pultruded profiles, and it is different from the FRP molded grille.

- Q:Are FRP pultrusion profiles resistant to hail or impact damage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to hail or impact damage. The combination of reinforcing fibers, such as carbon or glass, and a polymer resin matrix provides exceptional strength and durability to FRP pultrusions. These profiles have superior impact resistance compared to other materials like wood, steel, or aluminum. FRP pultrusion profiles are designed to withstand harsh environmental conditions, including hailstorms. The composite nature of FRP allows it to absorb and distribute impact energy, preventing the formation of cracks or fractures. This makes them an ideal choice for applications that require resistance to hail or impact damage, such as building facades, bridges, handrails, or utility poles. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, meaning they can withstand heavy impacts without compromising their structural integrity. They are also non-corrosive, which makes them immune to rust or degradation caused by hail or impact. In summary, FRP pultrusion profiles are highly resistant to hail or impact damage due to their composite construction and excellent strength-to-weight ratio. They provide a reliable and long-lasting solution for applications that require durability and resistance to harsh environmental conditions.

- Q:Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

- Q:Are FRP pultrusion profiles resistant to alkaline substances?

- FRP pultrusion profiles are known for their general resistance to alkaline substances. By using fiberglass reinforced polymer (FRP) in pultruded profiles, they acquire excellent resistance against a wide range of chemicals, including alkaline substances. The manufacturing process typically involves using a thermosetting polymer, such as polyester or vinyl ester, as the resin. This choice of resin ensures high resistance to alkaline solutions. Additionally, the fiberglass reinforcement adds strength and durability to the profiles, making them highly resistant to corrosion and degradation caused by alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the resin formulation and manufacturing process used. Therefore, it is advisable to consult the manufacturer or supplier to confirm that the profiles meet the specific resistance requirements for alkaline environments.

- Q:Are FRP pultrusion profiles resistant to ultraviolet radiation?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are typically resistant to ultraviolet (UV) radiation. The nature of the materials used in FRP profiles, such as fiberglass and resins, provides inherent UV resistance. These profiles are manufactured using a pultrusion process that involves impregnating reinforcing fibers with a UV-resistant resin matrix and then curing them. This combination of materials and manufacturing technique ensures that FRP pultrusion profiles can withstand prolonged exposure to UV radiation without significant degradation or loss of mechanical properties. As a result, FRP pultrusion profiles are commonly used in outdoor applications where UV resistance is essential, such as construction, infrastructure, and marine industries. However, it is important to note that the level of UV resistance can vary based on the specific composition of the FRP profile and the quality of the manufacturing process. Therefore, it is always recommended to consult the manufacturer's specifications and guidelines for the specific product being used to ensure its suitability for UV-exposed environments.

- Q:What are the typical applications of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have a wide range of applications due to their unique properties. Some of the typical applications of FRP pultrusion profiles include: 1. Construction and Infrastructure: FRP profiles are used for various structural elements in buildings, bridges, and other infrastructure projects. They are commonly used for beams, columns, decks, and reinforcement due to their high strength-to-weight ratio, corrosion resistance, and durability. 2. Industrial and Chemical Processing: FRP profiles are extensively used in the industrial sector for applications such as platforms, walkways, ladders, and handrails. They offer excellent resistance to chemicals, heat, and corrosion, making them suitable for harsh environments. 3. Electrical and Telecommunication: FRP profiles are utilized for cable trays, ladder racks, and support structures in electrical and telecommunication systems. They provide electrical insulation and are non-conductive, ensuring safety and reliability in these applications. 4. Transportation: FRP profiles find applications in the transportation industry, particularly in the manufacturing of lightweight components for vehicles, including buses, trains, and trucks. They help reduce weight, improve fuel efficiency, and enhance the overall performance of these vehicles. 5. Marine and Offshore: FRP pultrusion profiles are well-suited for marine and offshore applications due to their resistance to saltwater, UV radiation, and harsh environmental conditions. They are used for boat hulls, piers, dock fenders, and other offshore structures. 6. Recreation and Sports: FRP profiles are employed in the production of various recreational equipment such as ladders, slides, playground equipment, and sports accessories. Their high strength, durability, and resistance to weather elements make them ideal for these applications. 7. Water Treatment and Wastewater Management: FRP profiles are widely used in water treatment plants, sewage systems, and wastewater management facilities. They are used for grating, handrails, ladders, and other structural components due to their resistance to chemicals and corrosion. Overall, the versatility, strength, corrosion resistance, and lightweight nature of FRP pultrusion profiles make them suitable for a diverse range of applications in different industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords