Dental Floss Available Wholesale OEM Individually Floss Mint Waxed 50yds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Dental Floss Durable Portable Hygienic Cleanliness Restaurant Household Flossing

Brand: OEM/Ok Floss

Floss material:TPFE

Floss length:50m/OEM

Wax:Import germany wax/american wax/bee wax/candelilla wax/customized wax

Flavor:Mint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss: original color

Floss original color:Individual bulk PP box/as customized

Applications:Family,Hotel,Travel,Supermarket

Delivery:By sea,By air,By express.

Lead time:20-30days

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots

where your toothbrush can’t reach, generally between your teeth and under the gumline.

FAQ

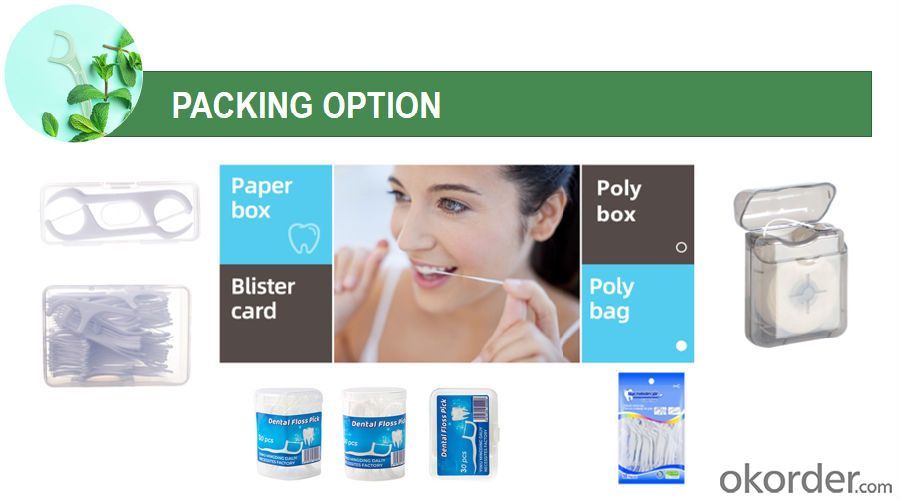

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

- Q:How does medical plastic contribute to the development of minimally invasive procedures?

- Medical plastic plays a crucial role in the development of minimally invasive procedures by providing the necessary tools and devices that enable healthcare professionals to perform these procedures safely and effectively. The use of medical plastic allows for the production of lightweight, flexible, and biocompatible instruments, such as catheters, endoscopes, and laparoscopic tools, which can be easily inserted into the body through small incisions or natural orifices. This reduces the need for large surgical incisions, leading to less trauma, shorter recovery times, and lower risk of complications for patients. Additionally, medical plastic offers excellent visibility, sterilization capabilities, and compatibility with medical imaging technologies, further enhancing the success and precision of minimally invasive procedures.

- Q:What are the characteristics of medical plastics that make them suitable for medical devices?

- Medical plastics have several characteristics that make them suitable for medical devices. Firstly, they are biocompatible, meaning they do not elicit a harmful response from the body and can be safely used in contact with human tissue or fluids. Secondly, they have excellent sterilization capabilities, allowing them to withstand high temperatures and various sterilization methods without compromising their structural integrity. Additionally, medical plastics offer good chemical resistance, making them resistant to degradation or corrosion from exposure to various substances found in medical environments. They also possess desirable mechanical properties such as flexibility, durability, and impact resistance, which are crucial for the functionality and reliability of medical devices. Finally, medical plastics can be easily molded into complex shapes, allowing for the production of intricate designs required for specific medical applications.

- Q:Potassium Permanganate can use disposable plastic gloves

- Because the rubber gloves will be Potassium Permanganate corrosion, in the middle of the textbooks we know that strong pH is highly corrosive, and rubber gloves are made of rubber, which belongs to the high molecular structure of aromatic hydrocarbon saturation, corrosion will produce a chemical reaction.

- Q:Is polyurethane a plastic product?

- Commonly used monomers, such as toluene diisocyanate, diisocyanate, two benzene methane, etc.. Polyols can be divided into 3 categories: simple Polyols (ethylene glycol, glycerol etc.); polyester oligomer containing terminal hydroxyl groups, used in the preparation of polyester polyurethane; containing terminal hydroxyl polyether oligomer, used for the preparation of polyether polyurethane. Polymerization methods vary with material properties. Synthetic elastomer before preparation of low molecular weight diols, and aromatic isocyanate and excessive reaction, generate isocyanate terminated prepolymer, and butylene glycol chain extender, thermoplastic elastomer; if using two aromatic diamine chain extender and further crosslinked, get casting elastomer. The prepolymer obtained elastic fiber by hydrazine or two amine chain expansion; the prepolymer with too much isocyanate was mixed with catalyst and foaming agent to obtain the rigid foam. If the monomer, polyether, water, catalyst and other mixed, a step reaction can be obtained soft foam. The monomer reacts with polyols in solution to obtain paint; the adhesive mixes and reacts with polyisocyanate monomers and low molecular weight polyesters or polyethers in use.

- Q:Are medical plastics resistant to cracking?

- Yes, medical plastics are typically designed to be resistant to cracking. They are manufactured using materials and additives that enhance their durability and flexibility, making them less prone to cracking under stress or pressure.

- Q:How do medical plastics contribute to the field of rehabilitation medicine?

- Medical plastics play a crucial role in the field of rehabilitation medicine by providing innovative solutions for various medical devices and aids. These plastics are lightweight, durable, and often customizable, allowing for the development of prosthetics, orthotics, and assistive devices that improve mobility and functionality for individuals with physical disabilities. Additionally, medical plastics are used in the production of rehabilitation equipment such as braces, splints, and supports, ensuring comfort, flexibility, and proper alignment. Their contribution to rehabilitation medicine helps enhance the quality of life for patients and facilitates their recovery and rehabilitation process.

- Q:How does medical plastic help in catheterization?

- Medical plastic is used in catheterization to manufacture catheters, which are flexible tubes inserted into the body to drain urine or administer medications. The use of medical plastic in catheters allows for a smooth and comfortable insertion, as it is soft and flexible. Additionally, medical plastic is biocompatible, meaning it is not harmful or toxic to the body, reducing the risk of adverse reactions or infections. Furthermore, medical plastic catheters can be designed with specific features like lubrication or anti-infection coatings, enhancing the overall effectiveness and safety of catheterization procedures.

- Q:How does medical plastic help in reducing the risk of medical errors?

- Medical plastic helps in reducing the risk of medical errors by providing a safe and sterile environment for medical devices and equipment. It prevents contamination and infection by being easy to clean and disinfect. Additionally, medical plastics are often transparent, allowing healthcare professionals to easily monitor and identify any potential issues or errors. Their durability and flexibility also contribute to the overall safety and reliability of medical devices, minimizing the risk of malfunctions or mistakes during procedures.

- Q:What is the harm of smashing plastics to the human body?

- If it is to crush the chemical raw material container, there may be residual chemical raw material pollution. Also need to pay attention to a problem, it is also a very important and easily overlooked problem is that no pollution, necessary cleaning in contact with these powder, no change of clothing, may put the pollutants home, even after the meal was eaten, it will be more of a heavy pollution way. Except for the problem of pollution, there is the problem of dust.

- Q:Can medical plastic be used in bioresorbable implants?

- Yes, medical plastic can be used in bioresorbable implants. Bioresorbable implants are designed to gradually degrade and be absorbed by the body over time. Medical plastics, such as polylactic acid (PLA) and polyglycolic acid (PGA), are often used in the manufacturing of bioresorbable implants due to their biocompatibility and ability to safely degrade within the body. These materials can provide the necessary mechanical strength and support during the healing process before gradually breaking down and being absorbed by the body.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dental Floss Available Wholesale OEM Individually Floss Mint Waxed 50yds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches