49-53% SiO2 Wollastonite Manufactured in China for glaze

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 103 m.t.

- Supply Capability:

- 2030 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

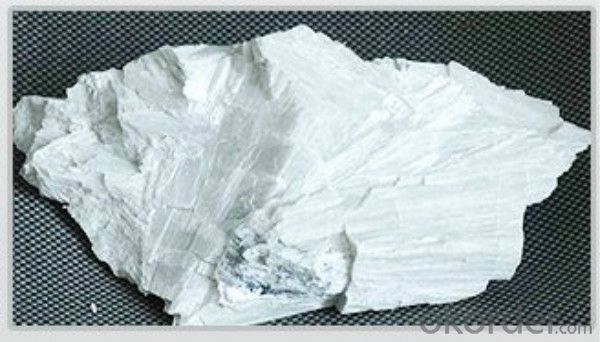

Brief Introduction

Wollastonite is featured with good heat resistance, hard wearing and corrosion resistance, and strengthening and reinforcing functions. Being innocuous, flavorless, and non-radioactive, wollastonite is environmental type functional material that is extensively applied in the fields of plastics, rubber, paint, friction materials, building materials and metallurgy protection.

With high quality, reasonable price and timely delivery, our products have been export to many foreign countries and areas, such as South Korea, Japan, Turkey etc. our company has got praise in both domestic and foreign markets.we have been the trusted and preferred supplier to the mineral&chemical products and the market share is growing rapidly and firmly. Warmly welcome all friends from domestic and abroad to cooperate with us. It is playing more and more imortant role in the industry.,

Features

1.Sample for free for your test.

2.Provide professional product consultation.

3.Offer competitive price.

4.Have precise quality control department.

5.Taking photos during the production and shipment, send the photos to customers;

6. Documents Department, to serve customer professionally.

7.Always think of the customers and make the add-value.

Specifications

Wollastonite Specfications | SiO2 | CaO | Fe2O3 | LOI | Whiteness | Size |

Glaze grade A | ≥49% | ≥44% | ≤0.3% | ≤2% | ≥90 | 200-400mesh |

Glaze grade B | ≥49% | ≥44% | ≤0.3% | ≤3% | ≥90 | 200-400mesh |

Ceramic-Body Grade | ≥41% | ≥39% | ≤0.5% | ≤8% | N/A | 0-400mesh |

Paint Grade A | ≥49% | ≥44% | ≤0.5% | N/A | ≥90 | 325-2000mesh |

Paint Grade B | ≥30% | ≥40% | ≤0.5% | N/A | ≥91 | 325-2000mesh |

Filler Grade | ≥49% | ≥43% | ≤0.3% | ≤4% | ≥90 | 200-2000mesh |

Welding Grade | ≥45% | ≥40% | ≤0.8% | S≤0.04% | P≤0.04% | 60-325mesh |

Pictures

FAQ

1 What is the packing and shipment?

In jumbo bag with pallet and without pallet

In bulk container

2 What is the Payment term?

T/T with down payment, L/C, D/P

3 What is the Delivery time?

Within 15 days after receiving the down payment or the LC draft

- Q:I know that sometimes ceramics from other countries do not follow US FDA standards for lead content.I want to make tea in ceramic mugs but they are all made in china so I‘m afraid they‘ll leak lead.Also.is it safe to head substances in plastic cups or mugs? Like big ones that are meant to last.not the ones you can crush with you hand.Also is it safe to reuse plastic bottles?

- The cup should be fine, it will be covered in a glaze with if there was lead in the ceramic then it wouldnt leak through, all my cups are made in china and im still here :D. And yes its perfectly safe to reuse plastic bottles, just make sure you wash them well or your next drink will taste a bit funny. and if you meant 'heat' in a plastic cup. them maybe, some melt when they have hot liquids in them. but you should be fine, like you said, they are the ones built to last, i heat liquids in those.

- Q:Has anyone used ceramic paint pens? I hope they are more manageable than ceramic paint + paintbrush (I‘m not so skilled at painting). Where can I find good multicolored ceramic paint pens? Like, what store? I don‘t want to buy online :(Thanks!

- Try to relax and enjoy the rideI have a feeling, since you are a new rider that you may be very tense and on edge when you ride. You should always be alert, however you need to stay calm and be sure to breath.

- Q:I bought a ceramic mold and thought I would be able to pour my faster plaster into it and easily separate the two halves and have little figurines. The plaster isn‘t coming out. The plaster is 12 hours into it‘s set time of 24, but it‘s not coming out even with hitting/tapping, and doesn‘t release even with my exacto knife. So obviously I am extremely disappointed. I have never done this before and am now wondering if it was intended for slip casting or I should have used some other material instead of plaster. I was trying to make the figurines for my plastercraft halloween village, which are made from plaster. Is there anything I can use to get it out fairly cleanly? I have tried to run it under hot and warm water to see if it would release or expand and I could pull pieces out, but it didn‘t seem to do much. I‘m very disappointed. For future reference, do I need to apply some sort of release material to make whatever I use not stick to the mold? Hopefully someone has some advise I can use.

- Sounds like you may have ruined it. But if you want to spend the time you may with some care be able to dig the plaster out using a Dremel type drill and/or small dental tools. Using plaster in any rigid mold will require a mold release, be it Vaseline applied to the mold or sealing the mold with a water proof sealant that will dry. If the mold were made from flexible silicone or some other plastic, a mold release wouldn't be needed. New wet plaster will bond to dry set plaster,mainly because the dry ,set unsealed plaster having minute holes in the surface and is porous draws the wet plaster into itself However if the plaster mold is to be used for slip casting do not seal it with any thing because the plaster mold is supposed to draw moisture from the slip allowing it to shrink away from the mold so there is no need for a mold release.

- Q:What about ceramics?

- Three, casting:The pile of good porcelain clay into a large turntable, by rotating the turntable by hand, and the tool will pull into ceramic porcelain clay.Four, printing blank:The drawn porcelain billet is only a prototype, and it needs to choose different impressions according to the shape to be made, and the porcelain blanks are printed into different shapes.Five. Trimming:Just printed good rough, uneven thickness, the need to repair the billet, this process will be printed on the repair of the billet, scraping, neat and symmetrical.Six, keep water:Na water is a necessary process, that is washed with water to remove the dust on the blank, prepare for the next draw blank and glazing process.

- Q:I‘ve noticed that many of the ceramic pots/planters on the market this year don‘t come with a hole at the bottom. I bought a few that are beautiful, but they‘re useless if they hold water and my roots will rot.Anyone know of a good way to make a hole in the bottom without breaking the pot?Will a standard electric drill bit work?

- This Site Might Help You. RE: How can I put a hole in a ceramic pot? I've noticed that many of the ceramic pots/planters on the market this year don't come with a hole at the bottom. I bought a few that are beautiful, but they're useless if they hold water and my roots will rot. Anyone know of a good way to make a hole in the bottom without breaking the.

- Q:i was wondering because i have alot of scrap copper and i wanted to pour it into coins, my mom has a ceramic mold of a coin and i was wondering if i could use it to pour into

- It is as advertised. Echtes Leder is German for Genuine Leather. The lining is viscose, which I think is a type of polyester or acetate.

- Q:What is the difference between ceramic tile and ceramic tile?

- The difference between ceramic tiles and ceramic tiles lies in water absorption. Water absorption is less than 0.5% for tile, more than 10% for ceramic brick, between the two half porcelain. The common variety of polished tiles, glazed tile, sanitary ware is the most porcelain, bibulous rate is less than 0.5%; small antique brick, tile (the wall), crystal tiles, wear-resistant bricks, Yaguang brick is brick, half tiles, bibulous rate is 0.5% tiles, ceramic pipe, decorative tile, glass products etc. are generally ceramic, water absorption rate of >10%.

- Q:wich is better?

- I would go with ceramic braces or braces in general. The problem with Invisalign is if it hurts you'd just immediately take it off and neglect to wear it (unintentionally of course). With braces, you'll always have them on. You also won't lose your braces while eatting. I know some patients have lost their Invisialign trays on accident.

- Q:Development history of Chinese ceramics

- Ceramic culture in Ming and Qing DynastiesBefore the Ming Dynasty ceramic glaze with green, the Ming Dynasty white porcelain for the bulk, creating materials for porcelain decoration. At the beginning of the Qing Dynasty porcelain skills reached a historical peak, the early and mid Qing Dynasty, the whole society, Kangxi, Yong Zheng and Qian Long three dynasties social economy has entered a period of prosperity, China's porcelain craft reached a historical peak, ceramics have greater progress, all existing technology and varieties of the Ming Dynasty mostly, improvement or innovation.

- Q:Cement, ceramics, glass production, chemical differentiation of raw materials

- Cement is mainly silicate, metal oxide, and gypsumThe main component of silica, alumina, potassium oxide and sodium oxide, calcium oxide, ferric oxide, titanium oxide, Magnesium Oxide etc.Glass is also the main component of silica, calcium silicate, sodium silicate and so on

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

49-53% SiO2 Wollastonite Manufactured in China for glaze

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 103 m.t.

- Supply Capability:

- 2030 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords