304 stainless steel,stainless steel sheet,stainless steel plate in china

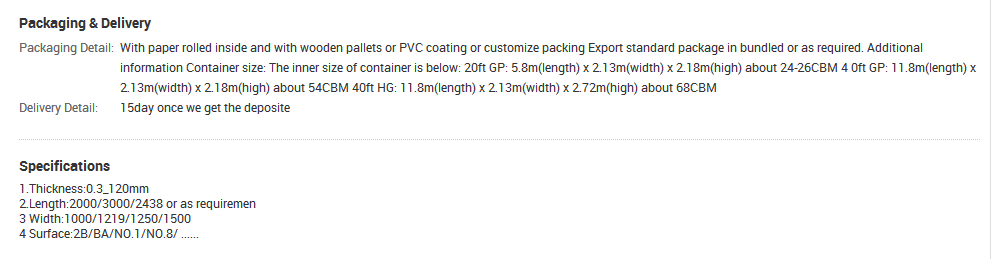

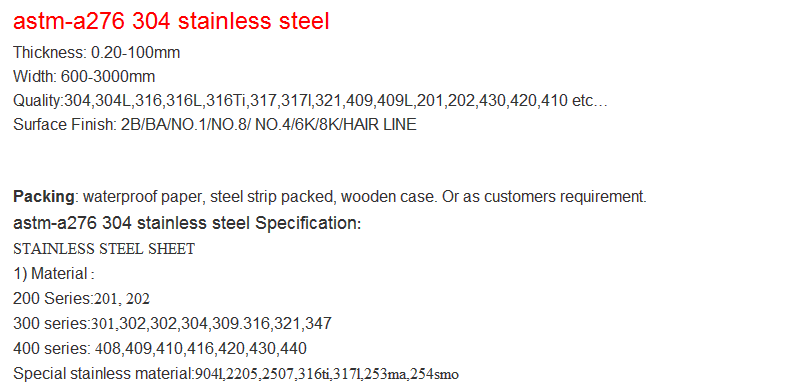

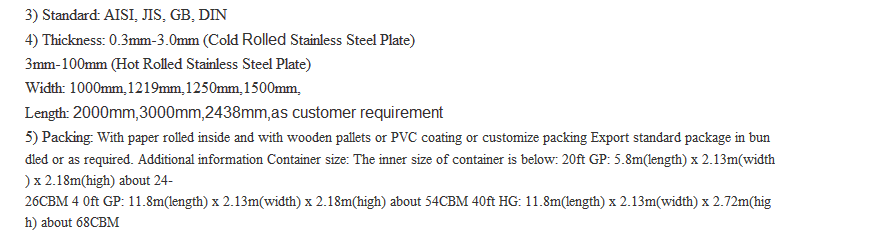

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What is the typical wall thickness of stainless steel pipes?

- The typical wall thickness of stainless steel pipes can vary depending on the specific application and industry requirements. However, it is common to find stainless steel pipes with wall thickness ranging from 0.065 inches (1.65 mm) to 0.250 inches (6.35 mm).

- Q:How do stainless steel pipes compare to concrete pipes?

- The advantages and disadvantages of stainless steel pipes and concrete pipes differ, and their suitability for specific applications may vary. Stainless steel pipes possess durability, corrosion resistance, and a high strength-to-weight ratio. They can withstand extreme temperatures, making them ideal for applications that involve high-pressure fluids or gases, such as in the oil and gas industry. Additionally, stainless steel pipes are commonly utilized in food processing, chemical plants, and wastewater treatment facilities due to their hygienic properties and chemical resistance. Moreover, they have a smooth interior surface, reducing friction and enabling efficient fluid flow. On the other hand, concrete pipes are recognized for their strength, longevity, and resistance to external loads. They are frequently employed in sewer systems, stormwater drainage, and culverts due to their ability to withstand heavy traffic loads and high groundwater pressures. Furthermore, concrete pipes are fire-resistant and provide excellent insulation, making them suitable for applications requiring fire protection. In terms of cost, stainless steel pipes generally have a higher price than concrete pipes. However, stainless steel pipes necessitate minimal maintenance and have a longer lifespan, which can compensate for the initial cost. Conversely, concrete pipes, though cheaper, may require more frequent repairs and have a shorter lifespan. Ultimately, the selection between stainless steel pipes and concrete pipes depends on the specific project requirements, including the intended application, environmental conditions, budget, and anticipated lifespan. Seeking advice from a professional engineer or pipe materials specialist can ensure the appropriate choice of pipe material for a given project.

- Q:What are the dimensions and sizes of stainless steel pipes?

- Different industrial and commercial applications are served by stainless steel pipes of varying dimensions and sizes. The sizing of these pipes is determined by their nominal diameter (DN) and the schedule or wall thickness. The nominal diameter represents the approximate internal diameter of the pipe and is commonly expressed in inches or millimeters. The most frequently available stainless steel pipe sizes range from 1/8 inch (3.175 mm) to 48 inches (1219 mm) in nominal diameter. However, larger sizes can be custom-made to meet specific requirements. The schedule or wall thickness of stainless steel pipes is indicated by a schedule number, which reflects the thickness of the pipe's walls. The most commonly used schedules for stainless steel pipes include Sch 5, Sch 10, Sch 40, and Sch 80. The higher the schedule number, the thicker the walls of the pipe. Apart from the dimensions and sizes, stainless steel pipes also come in various lengths, typically ranging from 20 feet (6.1 meters) to 40 feet (12.2 meters). Custom lengths can also be ordered based on specific project needs. It is important to note that these dimensions and sizes may differ based on the standards and specifications established by different countries and industries. Hence, it is crucial to consult the relevant standards or collaborate with a reliable supplier to ensure the precise dimensions and sizes of stainless steel pipes for a particular application.

- Q:What is the difference between 304H and 316H stainless steel pipes?

- The main difference between 304H and 316H stainless steel pipes lies in their chemical composition and corrosion resistance properties. 304H stainless steel contains higher levels of carbon than 316H, which provides it with improved high-temperature strength and resistance to sensitization. On the other hand, 316H stainless steel has higher levels of molybdenum and nickel, leading to enhanced corrosion resistance and suitability for use in more aggressive environments, such as marine applications. Overall, the choice between 304H and 316H stainless steel pipes depends on the specific requirements and environmental conditions of the application.

- Q:Can stainless steel pipes be used for underground applications?

- Yes, stainless steel pipes can be used for underground applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions found underground, making it a suitable choice for various underground applications such as drainage systems, sewage pipes, and water supply lines.

- Q:Can stainless steel pipes be tempered?

- No, stainless steel pipes cannot be tempered.

- Q:304 stainless steel pipe, 20*2 pressure, how many kilograms?

- 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 is equivalent to 0Cr19Ni9 in our country(0Cr18Ni9) stainless steel. 304 chromium 19%, containing nickel 9%. The 304 is the most widely used stainless steel, heat-resistant steel, steel, steel industry utility. For food production equipment, general chemical equipment, nuclear energy, etc..

- Q:Can stainless steel pipes be used for brewery and beverage industry applications?

- Yes, stainless steel pipes can be used for brewery and beverage industry applications. Stainless steel is highly resistant to corrosion, making it suitable for handling liquids and beverages. It is also easy to clean and maintain, ensuring the hygienic requirements of the industry are met. Stainless steel pipes are commonly used in these industries due to their durability, longevity, and compatibility with various fluids.

- Q:Are stainless steel pipes suitable for heat recovery systems?

- Stainless steel pipes, indeed, prove to be apt for heat recovery systems. With its exceptional durability and resistance against corrosion, stainless steel emerges as an ideal material for applications that involve extreme temperatures and harsh environments. The primary objective of heat recovery systems is to seize and exploit waste heat generated from industrial processes, and stainless steel pipes efficiently handle the heat transfer procedure while ensuring their steadfastness over time. Moreover, stainless steel showcases remarkable thermal conductivity, which further enables efficient heat transfer. Consequently, the utilization of stainless steel pipes in heat recovery systems guarantees utmost performance and longevity.

- Q:Can stainless steel pipes handle high temperatures?

- Yes, stainless steel pipes are capable of handling high temperatures. Stainless steel is known for its excellent heat resistance, making it suitable for various applications that involve elevated temperatures. The specific grade of stainless steel used will determine the maximum temperature the pipes can withstand. For instance, austenitic stainless steel grades such as 304 and 316 can typically handle temperatures up to around 1600°F (870°C), while higher alloyed grades like 310 and 321 can withstand even higher temperatures. This heat resistance is due to the presence of chromium and other alloying elements in stainless steel, which form a protective oxide layer that prevents corrosion and oxidation at high temperatures. Therefore, stainless steel pipes are commonly used in industries such as petrochemical, power generation, and heat exchangers, where high temperatures are prevalent.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 stainless steel,stainless steel sheet,stainless steel plate in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords