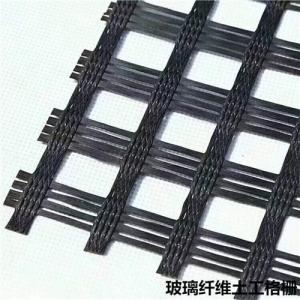

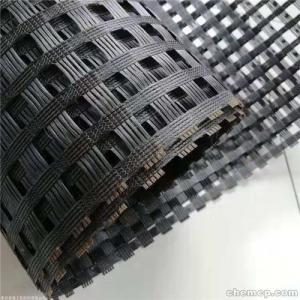

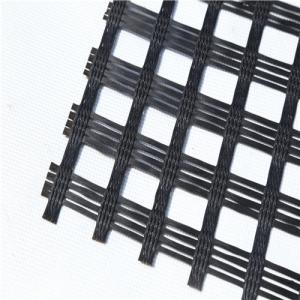

Fiberglass Geogrid with Asphalt Coating for Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Fiberglass Geogrid Specification

Tensile Strength: 25-25KN, 30-30KN, 50-50KN, 80-80KN, 100-100KN, 120-120KN,

Roll Size: 3.95x100m, as request,

Fiberglass Geogrid Application

1) Roadbed reinforcement, prevent road surface crack.

2) Road reconstruction

3) Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

Packaging & Delivery

Packaging Details: PP bags or PE film. Or Packed as customers' requests;

Delivery Detail: 10-20days after the payment received.

Remarks: we are very large fortune 500 enterprise with more than 20branches in worldwide, and have almost ten years export experience in geosynthetic field. We have kunlun bank account and have many Iran geosynthetics customers.So if any question or support, please just feel free to contact me at any time.

- Q:Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Polyester warp knitted polyester coating is PVC glue, glass fiber geogrid is that sensitive asphalt rubber. An anti-corrosion, a alkali resistance. Material is not the same, the appearance is not difficult to distinguish between experts

- Q:How do geogrids improve the performance of paved and unpaved roads?

- Geogrids improve the performance of paved and unpaved roads by providing reinforcement and stabilization to the soil and pavement layers. They distribute loads more evenly, reducing the formation of cracks and potholes. Geogrids also enhance the tensile strength of the road, allowing it to withstand heavier traffic and minimize deformation. Overall, geogrids increase the durability, lifespan, and structural integrity of both paved and unpaved roads.

- Q:Geogrid TX160 what does that mean?

- It has a high degree of three-dimensional mesh screen, which is used in civil engineering to increase the bearing capacity of the foundation and improve the crack resistance of the pavement.

- Q:Fiberglass grille width

- Glass fiber molded grating 1.5--1.6 fiberglass pultruded grid 1.6--1.8

- Q:How do geogrids help with slope stabilization?

- Geogrids help with slope stabilization by providing reinforcement and increased stability to the soil. They are typically made of high-strength materials and are installed within the slope to distribute the forces and prevent soil erosion. The geogrids interlock with the soil particles, creating a stronger and more stable structure that can withstand the forces of gravity and external loads. Additionally, they reduce lateral movement of the soil, preventing slope failure and improving overall slope stability.

- Q:Can geogrids be used in coastal protection?

- Yes, geogrids can be used in coastal protection. Geogrids are commonly used in erosion control and stabilization projects, including coastal areas. They provide reinforcement to soil and help prevent erosion by increasing the overall stability of the coastline. Geogrids can be used in various coastal protection applications such as retaining walls, revetments, and slope stabilization, helping to mitigate the impact of waves, tides, and currents.

- Q:Details of fiberglass geogrid

- 2, anti fatigue crackIn the old cement concrete pavement asphalt overlay, its main function is to improve the use function of the road, and the contribution to the bearing capacity is not big. The asphalt overlay on the old asphalt concrete pavement is different, and the asphalt overlay will be combined with the old asphalt concrete pavement. Therefore, the asphalt overlay on asphalt concrete pavement, in addition to the emergence of reflective cracks, but also because of the long-term effects of fatigue cracks. We overlay load do stress analysis of old asphalt concrete pavement and the asphalt because of asphalt overlays under flexible surface cover layer of the same nature and the asphalt surface, when subjected to loads, road surface deflection will occur. The surface layer under pressure in direct contact with the wheel of the wheel load in asphalt overlay, the outside edge of the area, the surface layer by force, due to the two force regional force are different in nature, and close to each other, so in the junction of two force area is prone to damage force mutation. Fatigue cracking occurs under the action of long term loads.Fiberglass geogrid in bituminous surface layer, to the compressive stress and tensile stress dispersion in the two block of stress region is formed between the buffer zone, where the stress gradually changes instead of mutation, reduces the stress mutation on asphalt surface damage. At the same time, the low elongation of fiberglass geogrid reduces the deflection of pavement, which ensures that the pavement will not be deformed.

- Q:What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are two different types of geosynthetics used in various civil engineering and environmental applications. Geogrids are typically made of high-strength polymer materials, such as polypropylene or polyester, and are designed to provide reinforcement and stabilization to soil structures. They have a grid-like structure with open apertures, allowing soil particles to interlock within the grid, improving load distribution and preventing soil erosion. Geogrids are commonly used in slope stabilization, retaining walls, and road construction. On the other hand, geosynthetic clay liners (GCLs) are composite materials consisting of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is highly absorbent and expands upon contact with water, creating a low permeability barrier. GCLs are primarily used as hydraulic barriers for containment applications, such as landfill liners, pond liners, and wastewater treatment facilities. They provide excellent resistance to liquid flow and act as a barrier to prevent the migration of contaminants. In summary, the main differences between geogrids and geosynthetic clay liners lie in their composition, purpose, and applications. Geogrids focus on soil reinforcement and stabilization, while GCLs are primarily used as barriers to control liquid flow and prevent the migration of contaminants.

- Q:Can geogrids be used in ground reinforcement for recreational facilities?

- Yes, geogrids can be used in ground reinforcement for recreational facilities. Geogrids provide stability and reinforcement to the soil, making them suitable for applications such as sports fields, playgrounds, and running tracks. They help prevent soil erosion, improve load-bearing capacity, and enhance the overall durability of the ground, ensuring a safe and reliable surface for recreational activities.

- Q:How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing additional stability and reinforcement to the soil. They distribute the loads more evenly, prevent soil erosion, and increase the overall strength of the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with Asphalt Coating for Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords