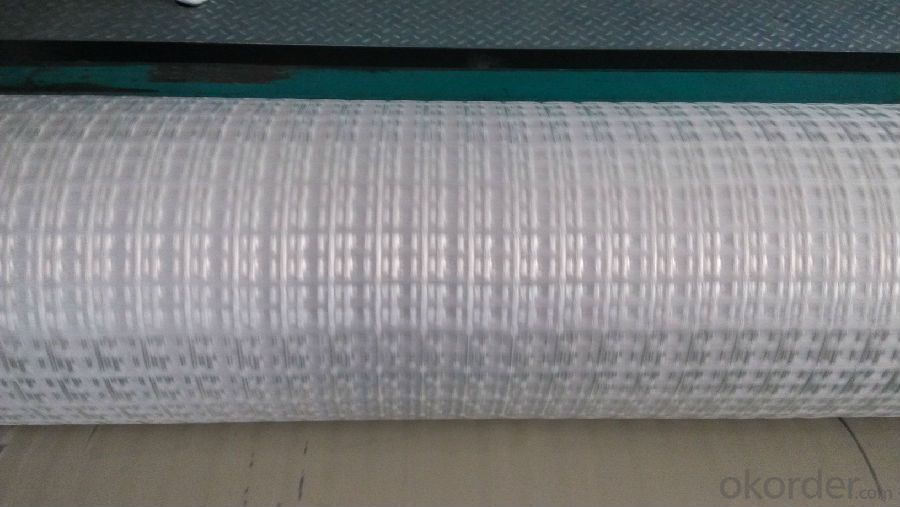

Fiberglass geogrid for Road - High quality geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

5.FAQ

Good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

- Q:How is fiberglass fabric printed?

- Fiberglass fabric is typically printed using a process called screen printing. In this method, a mesh screen is used to transfer ink onto the fabric, creating the desired design or pattern. The screen is prepared by blocking out areas that are not to be printed, and then ink is pushed through the screen onto the fabric using a squeegee. This allows for precise and durable printing on fiberglass fabric.

- Q:What are the different fiberglass fabric weaves for thermal insulation?

- There are several different fiberglass fabric weaves that are commonly used for thermal insulation purposes. These weaves are designed to provide excellent heat resistance and insulation properties. One of the most common weaves used for thermal insulation is the plain weave. This weave consists of a simple over-under pattern, where each weft thread passes alternately over and under each warp thread. The plain weave is known for its balanced strength and stability, making it suitable for a wide range of applications. Another popular weave for thermal insulation is the satin weave. This weave is characterized by a series of floating warp or weft threads that pass over several consecutive threads before being interlaced again. The satin weave creates a smooth and lustrous fabric with a high degree of flexibility and drapeability. It is ideal for applications where a lightweight and flexible insulation solution is required. The twill weave is another option for fiberglass fabric used in thermal insulation. This weave is characterized by a diagonal pattern created by the interlacing of the warp and weft threads. Twill weaves are known for their strength and durability, making them suitable for applications that require a more robust insulation solution. Additionally, the leno weave is often used for thermal insulation. This weave involves the twisting of adjacent warp threads around each other to create small, open spaces in the fabric. These spaces allow for improved air circulation and moisture management, making leno weave fabrics ideal for applications where breathability is important. Overall, the choice of fiberglass fabric weave for thermal insulation will depend on the specific requirements of the application, such as desired insulation properties, flexibility, strength, and breathability.

- Q:Is fiberglass fabric suitable for use in medical implants?

- Medical implants necessitate biocompatible materials, which do not induce any adverse reactions or harm to the human body. While fiberglass fabric possesses strength, durability, and resistance against high temperatures, its usage in medical implants is infrequent due to its potential to trigger inflammatory reactions, cause tissue damage, or generate toxic effects. Instead, medical implants frequently incorporate materials like titanium, stainless steel, or biocompatible polymers such as polyethylene or polyurethane. These materials have undergone extensive testing to guarantee their safety and compatibility with the human body. Additionally, they are engineered with specific properties that facilitate integration with surrounding tissues, stimulate healing, and minimize the risk of complications. To conclude, fiberglass fabric is unsuitable for medical implants because of its lack of biocompatibility. It is crucial for medical implants to be composed of materials that are safe, non-toxic, and well-tolerated by the body, ensuring successful outcomes and patient safety.

- Q:Is fiberglass fabric resistant to chemicals in water treatment facilities?

- Yes, fiberglass fabric is generally resistant to chemicals in water treatment facilities. It has excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents, making it a suitable choice for various applications in water treatment facilities.

- Q:How does fiberglass fabric compare to Kevlar fabric?

- Both fiberglass fabric and Kevlar fabric find extensive use in various industries due to their desirable properties. However, they possess distinct differences that make them suitable for different applications. To begin with, fiberglass fabric is woven together using fine strands of glass fibers. It is renowned for its exceptional strength and durability, making it a popular choice for applications that demand high tensile strength and resistance to abrasion. Moreover, fiberglass fabric exhibits excellent heat and chemical resistance, making it suitable for insulation, electrical components, and corrosion-resistant applications. On the contrary, Kevlar fabric is crafted from synthetic para-aramid fibers, which are known for their outstanding strength-to-weight ratio. In comparison to fiberglass fabric, Kevlar fabric is significantly stronger, boasting a higher tensile strength. This characteristic renders it ideal for applications where weight reduction and high impact resistance are critical factors, such as bulletproof vests, body armor, and aerospace components. Another notable contrast between these two fabrics lies in their heat resistance properties. Although fiberglass fabric showcases excellent heat resistance, Kevlar fabric exhibits remarkable flame resistance. Consequently, Kevlar fabric proves highly suitable for applications that prioritize fire protection, including firefighting suits and thermal insulation. In terms of cost, fiberglass fabric is generally more affordable than Kevlar fabric. The latter is relatively expensive due to its advanced manufacturing process and superior performance characteristics. In conclusion, the selection between fiberglass fabric and Kevlar fabric ultimately depends on the specific requirements of the application. Fiberglass fabric excels in providing strength, durability, and resistance to heat and chemicals, while Kevlar fabric offers an exceptional strength-to-weight ratio, impact resistance, and flame resistance.

- Q:What are the weight options for fiberglass fabric?

- Fiberglass fabric, also known as glass fiber cloth, is available in a variety of weight options to suit different applications. The weight of fiberglass fabric is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight options for fiberglass fabric can range from as low as 0.5 oz/yd² (17 g/m²) to as high as 32 oz/yd² (1086 g/m²) or even more. The weight of fiberglass fabric determines its thickness, strength, and durability. Lighter weight fiberglass fabrics are often used for applications that require high flexibility and conformability, such as in the manufacturing of circuit boards or for reinforcing and repairing small parts. They are also commonly used in aviation and aerospace industries, where weight reduction is crucial. On the other hand, heavier weight fiberglass fabrics are typically used in applications that require higher strength and impact resistance. These can include boat building, automotive parts manufacturing, construction, and even in the production of bulletproof vests and armor. It is important to note that the weight of fiberglass fabric is just one factor to consider when choosing the right fabric for a specific application. Other factors like weave pattern, finish, and resin compatibility should also be taken into account to ensure optimal performance.

- Q:Can fiberglass fabric be used for insulation in cryogenic applications?

- Yes, fiberglass fabric can be used for insulation in cryogenic applications. Fiberglass is known for its excellent insulating properties, as it effectively traps air pockets within its structure, reducing heat transfer. This makes it suitable for use in cryogenic applications where extremely low temperatures need to be maintained. Additionally, fiberglass is a non-flammable material, which is crucial for ensuring safety in cryogenic environments. It is also resistant to moisture and chemicals, which further enhances its suitability for use in cryogenic insulation. However, it is important to note that the specific type of fiberglass fabric used in cryogenic applications should be selected carefully. There are different grades and thicknesses of fiberglass fabric available, and the selection should be based on the specific requirements of the cryogenic application to ensure optimal insulation performance. In summary, fiberglass fabric can be used for insulation in cryogenic applications due to its excellent insulating properties, non-flammability, and resistance to moisture and chemicals. Proper selection of the specific type of fiberglass fabric is important to ensure the best insulation performance in cryogenic environments.

- Q:Can fiberglass fabric be used for reinforcement in pharmaceutical tanks?

- Yes, fiberglass fabric can be used for reinforcement in pharmaceutical tanks. Fiberglass fabric is known for its high strength-to-weight ratio and excellent resistance to corrosion, chemicals, and extreme temperatures. These properties make it an ideal material for reinforcing tanks in the pharmaceutical industry, where the tanks may come into contact with various chemicals and substances. Fiberglass fabric can provide structural support, increase the durability and lifespan of the tanks, and ensure they meet the required safety standards. Additionally, fiberglass fabric is lightweight, making it easier to handle and install in tank applications. Overall, the use of fiberglass fabric for reinforcement in pharmaceutical tanks is a reliable and efficient choice.

- Q:Can fiberglass fabric be used for insulation in industrial ovens?

- Yes, fiberglass fabric can be used for insulation in industrial ovens. Fiberglass fabric has excellent thermal insulation properties and can withstand high temperatures, making it an ideal choice for insulating industrial ovens. It can effectively trap heat, preventing it from escaping the oven, and thus improving energy efficiency. Additionally, fiberglass fabric is durable, resistant to chemical and moisture exposure, and has low thermal conductivity, making it a reliable and long-lasting option for insulation in industrial ovens.

- Q:When decorating, how can the waterproof of kitchen and toilet be checked and accepted?

- Do closed water test. The kitchen and bathroom were filled with water up to 20cm high. For 24 to 48 hours of closed water test, the water level was observed to drop significantly and to see if there was any water seeping from the ground floor. For the light wall, the water is detected to see if there is water leakage on the back.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass geogrid for Road - High quality geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords