Excellent quality Ceramic Fiber Sandwich board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

newly-designed ceramic fiber sandwich panel

1. widely application

2. DIN JIS standard

3. long life span

Ceramic fiber sandwich panel:

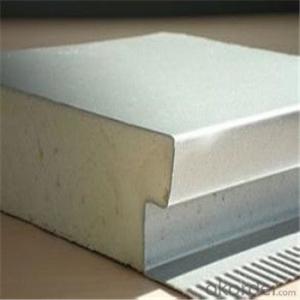

Ceramic fiber sandwich panel is shaped by rock wool and steel panel through automatic production line without further jointing at the site, it has good properities of heat preservation and sound insulation, heat insulation, fireproof.

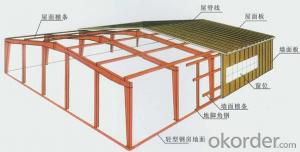

Usage: Widely used for the roof, exterior walls and internal partitions of industrial and civil buildings which have requirements of fire, sound insulation and thermal insulation, especially for the fire controlling projects.

Construction:

1)The upper and lower surfaces: Adopted by galvanized color steel plate, thickness 0.4-0.8mm. According to customer's specific need, it also can be used Galvanized color steel plate or aluminum plate. After rolling by the mould machinery the steel plate is stuck with the rock wool.

2)Rock wool core material: The density of rock wool block is 120kg/m3, it is staggered and rolled out with its fiber direction perpendicular to the upper and lower surface of the sandwich panel, the rock wool is closely-phase jointed filling the entire vertical and horizontal section of the sandwich panel. The rock wool between the blocks and steel sheet is shaped into one whole block by high-intensity foam, sophisticated process ensures high-density rock wool insulation between the inner body and metal plate can produce a very strong adhesion, which made rock wool sandwich panel has a strong stiffness.

Product Specifications:

1) Width <950mm/1150mm, length <120000mm can be fixed according to design requirements and transport conditions

2) Thickness: 50mm, 75mm, 100mm

Features:

1) Good Stiffness: After the polystyrene core material is shaped as a whole, and through heating and pressurizing, it is stuck to the surface of the steel plate. After figuration the sandwich panel has excellent integrity; And there is pressured waves on the upper surface on roof panel, the overall stiffness is better than other similar materials, by connected and fixed with the purlin the stiffness of the wall and roof panel is improved greatly.

2) Special deduction method: The access of the rock wool roof panel is connected by buckling, protecting the seam from leaking and save the installing parts of panel.

3) Strong and reasonable fixing method: The roof panel is fixed by the special made tapping M6 and jointed with the purlin thus it can resist typhoon and other the external force, the tapping is in the wave crest of the surface of the roof with special waterproof structure, moreover due to the special structures of the tapping, for example, there is a plastic cap on the screw cap to avoid leakage.

4) Short installation: No more process on the install site, it can not only keep clean of environment without influencing other production stages but also shorten the time of fixing back plate.

5) Anti-scratching: There is a pressure-sensitive adhesive film on the surface of the panel to protect the coating surface from scratching damage.

Advantages:

1) Good fireproof performance: Using rock wool materials, special process and formula, the sandwich panel has good fire performance. Tests showed that it can stand more than 1000 degree of the fire.

2)Good thermal insulation: The insulation thermal conductivity of the rock wool sandwich panel is low as λ = 0.043 W/m2 K,

3) Remarkable sound insulation and absorbtion

Sound insulation: The Rock wool sandwich panel has a significant reduction of noise transfer, it is particularly applied to place where there are regular flights. In addition, the indoor sound from the impact of the rain, hail, etc also decreased after using rock wool roof panel, but also significantly decreased.

According to ISO 717/82 and UNI 8270 / 7 criteria, sound insulation effect of rock wool sandwich panel with density of 100kg/m3 rock wool core material can achieve RW = 29 ~ 30 dB.

- Q:Similar to the color steel tile, floor board, the roof of the push is how much ah

- General wallpaper glue is sticky, you can consider using white latex to try.

- Q:How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q:This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- There is no harm have to brush your teeth ah ~ Do not you do not brush it? You are so powerful

- Q:What is the weight per unit area of 100 thick rock wool sandwich panels?

- First, the electricity management: ⒈ temporary electricity must be "" construction site temporary electricity safety technical specifications "JGJ46-88" compilation of electricity construction organization design and development of safe electricity technical measures and electrical fire protection measures. ⒉ temporary electricity engineering drawings must be drawn solely by the electrical engineering and technical personnel, after the approval of the technical person as a temporary basis for construction. ⒊ temporary electricity construction organization design content and steps: ⑴ site exploration, to determine the power line into the total distribution box (cabinet), the distribution of electrical box location and line direction. ⑵ load calculation, select the wire cross-section and electrical type, specifications. ⑶ draw electrical plan, elevation and wiring system diagram.

- Q:Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Flexible tube: flexible composite high-pressure transmission pipe products with patented technology installation and maintenance equipment, so that installation and maintenance more convenient, solid and reliable, to a greater extent reduce the cost of the project; no fire operations, greatly improving the oil field construction safety factor , Reducing the probability of personnel injury, and no need to rely on power supply, effectively shorten the installation and maintenance cycle, can quickly resume production; maintenance does not require cleaning lines Difference: composite pipe has good mechanical properties, with rust and oxidation resistance, acid and alkali, good resistance to intergranular corrosion and other chemical properties Flexible tube with good anti-tensile and anti-static, flame retardant performance; anti-fouling performance; flexible, light weight, transport fluid resistance is small, the use of free bending, long service life

- Q:Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q:What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q:Color steel room life in general how many years

- Safety information complete directory directory Chapter 1 construction site safety technical data management of the main content and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technology The establishment of the data Section IV of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (second file Box) Section III of the target management (the third file box) Section IV of the safe construction of the organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (The sixth file box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident ( The eleventh section of the security box (the eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (tenth File box) Section XII mechanical equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union Labor protection information

- Q:Color steel sandwich panels and synthetic resin tile which is more market

- Online shopping bar, do not go to the supermarkets to buy online shopping, then remember that can not be less than 250 points below the price of a sub-goods

- Q:The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Excellent quality Ceramic Fiber Sandwich board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords