6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Thick Plate for mold production

The alloy 6061 has very good welding characteristics and may be welded by all of the common welding techniques. Gas tungsten arc welding is generally used for thin sections and gas metal arc welding is used for heavier sections.Commonly used in the manufacture of heavy-duty structures requiring good corrosion resistance, truck and marine components, railroad cars, furniture, tank fittings, general structural and high pressure applications, wire products, and in pipelines.

2.Main Features of Aluminum Thick Plate for for Boat and Lighting:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

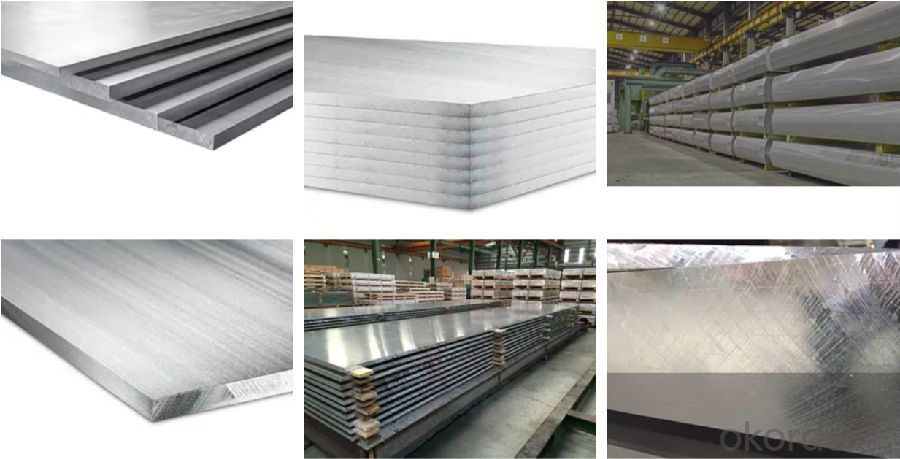

3. Aluminum Thick Plate Images:

4. Aluminum Thick Plate for for Boat and Lighting Specification:

Chemical Composition Limits for Aluminum Alloys

Composition in percent by weight according to The Aluminum Association. The values associates maximum limits unless shown as a range or a minumum.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others Each | Others Total | Al. Min. |

| 6061 | 0.40- 0.8 | 0.7 | 0.15- 0.40 | 0.15 | 0.8- 1.2 | 0.04- 0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1- 2.9 | 0.18- 0.28 | 5.1- 6.1 | 0.20 | 0.05 | 0.15 | Rem. |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.9 | 1.2- 1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchanging experience with several quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes and video,we will be responsible.

- Q:a 1 kg block of aluminum and a 1 kg block of lead are immersed in water, Both sink, but which experienced the greater buoyant force? Why?

- 1 kg of Aluminum will require more volume to occupy since it is lighter than lead. Lead has more density to Aluminum.So, when immersed in water Aluminum will displace more volume of water than lead. The buoyant force is equal to the Mass of water thus dispalced . Thus we can say Aluminum will experience more buoyant force.

- Q:Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- Durafix Aluminum

- Q:How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q:How do I clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, start by wiping them down with a soft cloth or sponge and a mild detergent or soap. Rinse the sheets thoroughly with clean water and dry them with a clean towel. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. To maintain the shine and prevent corrosion, you can apply a thin layer of aluminum polish or wax using a clean cloth. Regularly inspect the sheets for any signs of damage or oxidation, and address them promptly to ensure their longevity.

- Q:I broke the swing-arm of a cut-off saw, need to know how to weld it back. I have a stick welder and can weld steel, but have never messed with cast aluminum.

- Yes it could be welded with stick but the rod is hard to find (not that good of quality of weld too). Your best bet is to have it tig welded. If you have never welded aluminum then it is probably best to get someone to weld it for you. I would take it apart and take the parts to a weld shop and get an estimate on it. It may be cheaper to try to get the replacement parts from the manufacturer. Or look on eBay for a saw that's the same and try to find one that is damaged you'll get it cheaper. (30 + years welding - certified)

- Q:Are aluminum sheets non-magnetic?

- Indeed, aluminum sheets lack magnetic properties as they are not ferromagnetic. Instead, they fall under the classification of paramagnetic materials with a feeble reaction to magnetic fields. Consequently, aluminum sheets fail to exert any magnetic attraction or retention.

- Q:Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q:What is the color range available for aluminum sheets?

- Aluminum sheets come in a wide range of colors, offering a diverse selection. Standard colors include silver, black, white, bronze, and gold. Furthermore, aluminum sheets can be coated with different finishes, such as anodized, painted, or powder coated, which expands the color options even more. These coatings provide an array of colors, including vibrant shades like red, blue, green, yellow, and many others. Moreover, specialized processes enable the achievement of custom colors, allowing for personalized and unique choices. In summary, the color range for aluminum sheets is extensive and adaptable, meeting different aesthetic preferences and design needs.

- Q:Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile and efficient method that can be used to cut through a wide range of materials, including aluminum.

- Q:For my chem class that I just barely started taking, we're making bohr models. Even though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circles. I get everythign else about atoms except how they're actually made up lol. Maybe someone on here can explain it to me? I hope so because i have to make a model for it for friday.The element I'm asigned is aluminum btwYour help is greatly appreciated!

- Aluminum Bohr Model

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords