Tensar Triax Geogrid

Tensar Triax Geogrid Related Searches

Tensar Triaxial Geogrid Tensar Interax Geogrid Tenax Geogrid Triax Geogrid Triaxial Geogrid Tensar Tensar Uniaxial Geogrid Tensar Triax Tx170 Geogrid Geogrid Triax Tensar Triax Tx7 Geogrid Tensar Triax Tx140 Geogrid Tensar Biaxial Geogrid Tensar Triax Geogrid Price Tensar Triax Tx130s Geogrid Tensar Ux Geogrid Geogrid Tensar Tensar Triax 160 Geogrid Tensar Triax Tx 140 Geogrid Tensar Triax Geogrid Cost Tensar Triax Tx5 Geogrid Tensar Triax Tx160 Geogrid Tensar Structural Geogrid Triaxial Geogrid Triax Tx Geogrid Tensar Triax Geogrid Tx160 Tensar Geogrid Calculator Tensar Bx1100 Biaxial Geogrid Tensar Bx1100 Geogrid Tensar Type 2 Geogrid Tensar Geogrid Reinforcement Tensar Bx1200 Biaxial GeogridTensar Triax Geogrid Supplier & Manufacturer from China

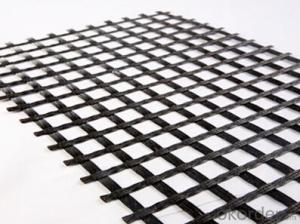

Tensar Triax Geogrid is a high-performance geosynthetic product designed to provide reinforcement and stabilization for various civil engineering applications. This advanced material is engineered to enhance soil strength, reduce settlement, and improve overall performance of the construction project. The Tensar Triax Geogrid is widely used in applications such as road construction, slope stabilization, retaining walls, and embankments, offering a reliable solution for soil reinforcement and erosion control. Its unique triaxial structure allows for uniform distribution of forces, ensuring optimal performance and durability in various soil conditions.The Tensar Triax Geogrid is a versatile product that caters to a broad range of usage scenarios, making it an essential component in modern civil engineering projects. It is particularly beneficial in situations where soil conditions are poor or where additional support is needed to prevent soil movement and maintain structural integrity. By incorporating this geogrid into the construction process, engineers can achieve greater stability, reduce material requirements, and minimize long-term maintenance costs. This makes the Tensar Triax Geogrid an invaluable tool for professionals in the field, contributing to the success and longevity of their projects.

Okorder.com is a leading wholesale supplier of Tensar Triax Geogrid, offering a vast inventory of this high-quality product to customers worldwide. As a reputable distributor, Okorder.com ensures that customers have access to the best materials at competitive prices, making it easier for them to source the geogrids they need for their projects. With a commitment to customer satisfaction and a focus on providing top-notch products, Okorder.com has established itself as a trusted source for Tensar Triax Geogrid and other geosynthetic materials.

Hot Products