Tensar Biaxial Bx Geogrids for High Tensile Strength Fiberglass in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

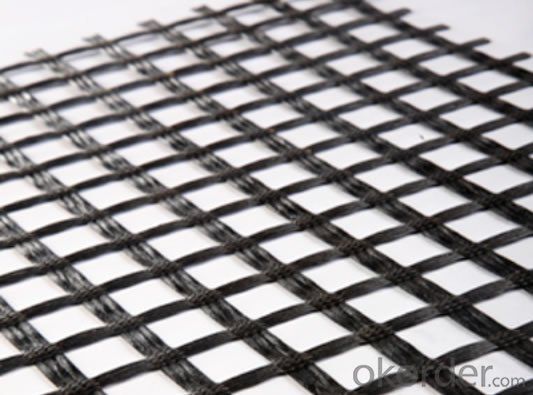

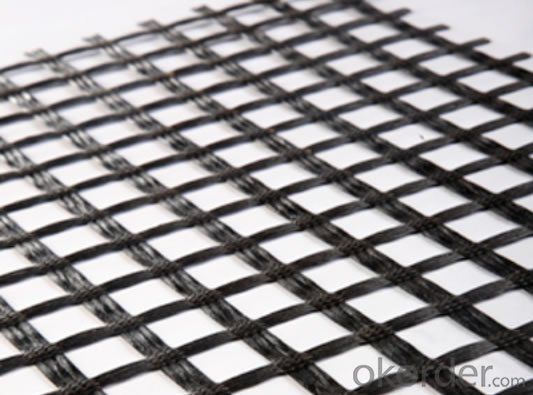

Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact polyethylene and polypropylene. Geogrids are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

Main application objects of the materials:

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and greek beds;

Fixation of the railroad cone slopes;

Support wall construction.

“Technostroytex” LLC geogrids are a honeycomb of polyethylene bands of 1.7 mm thickness (standard), bound by ultrasonic welding joints chequerwise.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids suitable for reinforcing steep slopes?

- Yes, geogrids are suitable for reinforcing steep slopes. Geogrids are commonly used in various civil engineering applications, including slope stabilization. They provide additional stability by distributing the forces exerted by the soil and preventing soil erosion. Geogrids are lightweight, flexible, and have high tensile strength, making them an ideal choice for reinforcing steep slopes and preventing potential landslides.

- Q: Can geogrids be used in railway construction?

- Yes, geogrids can be used in railway construction. Geogrids are commonly used to reinforce and stabilize the railway track substructure, providing improved load distribution and preventing soil movement. They help to increase the overall strength and stability of the track, making it more resistant to deformation and settlement. Additionally, geogrids can help reduce the maintenance needs of the railway infrastructure, making them a beneficial solution for railway construction projects.

- Q: Technical specifications of glass fiber grating

- Specification EGA1 * 1A-N EGA1 * 1CA-N EGA1 * 2A-N EGA2 * 2C-N EGA1 * 1A EGA1 * 1CA EGA1 * 1B EGA2 * 2A EGA2 * 2CA * 2B fracture strength of EGA1 * EGA2 * EGA2 * 2B-N * 1B-N * 1C * EGA2 *

- Q: How do geogrids improve the performance of mechanically stabilized slopes under dynamic loading?

- Geogrids improve the performance of mechanically stabilized slopes under dynamic loading by providing reinforcement and enhancing the soil's strength and stability. They distribute the applied forces more evenly, reducing stress concentrations and preventing slope failure. Additionally, geogrids increase the friction between soil particles, reducing lateral movement and maintaining slope integrity even during dynamic loading events such as earthquakes or heavy traffic.

- Q: What is the difference between a uniaxial and a biaxial geogrid?

- A uniaxial geogrid is designed to provide strength and stability in one direction, typically in the longitudinal axis. It is used to reinforce soil or other materials in applications such as road construction, retaining walls, and embankments. On the other hand, a biaxial geogrid is designed to provide strength and stability in both the longitudinal and transverse directions. It offers enhanced reinforcement capabilities and is commonly used in applications where multidirectional support is required, such as steep slopes, ground stabilization, and pavement systems.

- Q: Are geogrids resistant to biological clogging?

- Yes, geogrids are resistant to biological clogging. They are typically made from materials such as high-density polyethylene (HDPE) or polyester which are resistant to biological degradation. Additionally, geogrids have an open structure that allows for effective drainage and prevents the accumulation of organic matter that could lead to clogging.

- Q: Plastic grid plate making process

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. The plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: Can geogrids be used in reinforced slopes?

- Yes, geogrids can be used in reinforced slopes. Geogrids are commonly used in reinforced slopes to enhance the stability and strength of the soil. They are designed to distribute the load and provide additional reinforcement to the slope, improving its resistance against erosion and slope failures.

- Q: How do geogrids enhance the stability of steep railway cuttings?

- Geogrids enhance the stability of steep railway cuttings by providing reinforcement and increased tensile strength to the soil. These materials are placed within the soil to create a network of interconnected elements, which distribute and transfer loads more efficiently. This helps to resist the lateral forces exerted by the soil, preventing slope failure and maintaining the integrity of the railway cutting.

- Q: How do geogrids improve the load distribution in pavements?

- Geogrids improve the load distribution in pavements by providing reinforcement and increasing the stability of the structure. They distribute the load more evenly across the pavement, reducing stress on the layers beneath. This helps to prevent cracking, rutting, and other forms of pavement distress, ultimately extending the lifespan of the pavement.

Send your message to us

Tensar Biaxial Bx Geogrids for High Tensile Strength Fiberglass in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords