Platform Twin Bed Frame

Platform Twin Bed Frame Related Searches

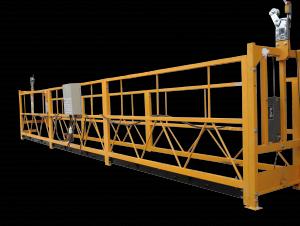

Platform Bed Frame Metal Double Bed Frame Platform Bed Iron Frame Bed King Size Platform Bed Shop Platform Beds Silver Bed Frame Iron Bed Frames Affordable Platform Beds Iron Full Bed Frame Iron King Bed Frame Bed Frame Wheels Stainless Steel Bed Frame Iron Beds Frames Metal Frames For Beds Twin Size Headboard Bed Stand Frame Custom Bed Backboard Render Board Suspended Platform Steel Frames For Furniture Iron Bunk Beds False Ceiling Frame Reasonably Priced Bunk Beds Double Hanging Egg Chair Touch Bedside Table Lamps Black Bedside Table Lamp Bunk Beds With Mattresses Bedside Table With LightPlatform Twin Bed Frame Supplier & Manufacturer from China

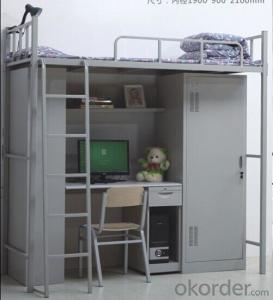

Platform Twin Bed Frame is a versatile and space-saving furniture item that offers a sturdy and comfortable sleeping surface. This type of bed frame is designed to eliminate the need for a box spring, providing a sleek and modern look while also maximizing the available floor space in a room. The Platform Twin Bed Frame is ideal for small apartments, dormitories, and any space where maximizing room is essential.The Platform Twin Bed Frame is widely used in various settings, such as residential homes, college dorms, and hotels, where space efficiency is a priority. This bed frame is particularly popular among individuals who prefer a minimalist design and those who want to reduce clutter in their sleeping area. It can accommodate a twin-sized mattress, making it suitable for children's rooms or as a guest bed in a small apartment.

Okorder.com is a leading wholesale supplier of Platform Twin Bed Frame, boasting a large inventory that caters to the needs of various customers. With a commitment to quality and affordability, Okorder.com ensures that the Platform Twin Bed Frame is available to a broad range of clients, from retailers to individual consumers. By offering a comprehensive selection of Platform Twin Bed Frame options, Okorder.com has established itself as a reliable source for this practical and stylish furniture item.

Hot Products