Platform Bed Frame

Platform Bed Frame Related Searches

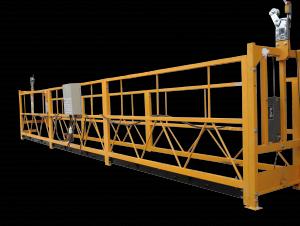

Platform Twin Bed Frame Platform Bed Shop Platform Beds Iron Frame Bed King Size Platform Bed Affordable Platform Beds Silver Bed Frame Bed Frame Wheels Iron Bed Frames Stainless Steel Bed Frame Iron King Bed Frame Metal Double Bed Frame Iron Full Bed Frame Metal Frames For Beds Iron Beds Frames Bed Stand A Frame Lifting Equipment Bed Backboard Platform Elevator Render Board Suspended Platform Iron Bunk Beds Frame Custom Inclined Platform Lift Reasonably Priced Bunk Beds False Ceiling Frame Bunk Beds With Mattresses Steel Frames For Furniture Bunk Beds For Girls Kids Canopy BedPlatform Bed Frame Supplier & Manufacturer from China

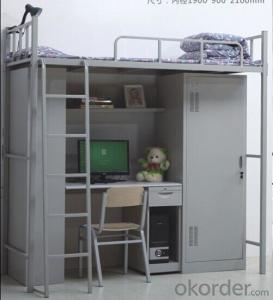

Platform Bed Frame, a versatile and stylish addition to any bedroom, typically includes a low-profile frame, slats, and sometimes a headboard. These bed frames are designed to provide a sturdy and stable sleeping surface without the need for a box spring, making them an ideal choice for those seeking a minimalist and space-saving solution. The sleek design of Platform Bed Frame complements a wide range of bedroom aesthetics, from modern to traditional, and can be easily adapted to various room sizes and layouts.Platform Bed Frame is widely used in residential settings, hotels, and dormitories due to its durability, affordability, and ease of assembly. This product is particularly popular in urban areas where space is at a premium, as it allows for maximized floor space and a clutter-free appearance. Additionally, Platform Bed Frame is an excellent choice for those who prefer a lower sleeping height, such as the elderly or individuals with mobility issues.

Okorder.com is a leading wholesale supplier of Platform Bed Frame, boasting a vast inventory that caters to a diverse range of customer needs. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Platform Bed Frame is manufactured to the highest standards, using durable materials and expert craftsmanship. This allows customers to enjoy a reliable and long-lasting product that not only enhances the comfort of their sleep but also adds a touch of elegance to their living space.

Hot Products