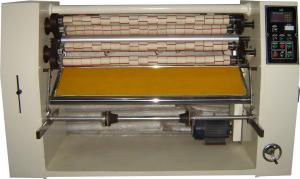

ZJ1300 x 3.0 Slitting line stainless steel cutting machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ⅰ. Technological Capability:

1.1 Raw material: carbon steel strip, fine steel strip, and low alloy steel strip

(σs≤350MPa,b≤500MPa )

1.2 Specification of raw material:

Thickness of steel strip 0.6 - 3.0mm

Width of steel strip 700 - 1300mm

Inner diameter of strip coil 508mm

Max Outer diameter of strip coil 1800mm

Max weight of strip coil 15 tons

1.3 Finished Product

Inner diameter of strip coil 610mm

Outer diameter of strip coil Max1800mm

1.4 Slitting capacity

quantity of srip 4- 15 strips

1.5 Max Line Speed 100m/min

1.6 Input Power: 380Volt, 3 phase, 4 lines, 50Hz.

1.7 Feeding Direction: Left side or right

II Technical flow:

Coil loader → Uncoiler → shovel board device → Feed Flattener → end shear → Centering device→ Slitter→ scrap winder → Accumulator →tension stand→ Recoiler→ Movable support→ Separating Presser → coil unloader

- Q: What is the arrangement principle of cutting order in machining?

- First datum, then other.That is to say, we should first process the surface that is used as the base of the precision, and then finish the other surfaces with the machined standard as the reference.

- Q: What is the relationship between metal cutting and numerical control machine tools?

- Metal cutting is more extensive, it can be said that the basic machinery belongs to.

- Q: Metal cutting machine tool manufacturing is mainly mechanical, machine, drilling machine, grinding machine etc.. Its safe operation

- The electric safety earthing; the rotating mechanism has the reliable protection device;

- Q: What is the rigidity of process system in metal cutting?

- The so-called process system stiffness, refers to the workpiece surface processing in the cutting force to the component Fp, the tool relative to the workpiece in the direction of the Y shift ratio: k=Fp/y

- Q: What is the difference between metal cutting machine tools and metal forming machine tools?

- Metal cutting machine tools are cutting, grinding or special processing methods to process all kinds of metal workpiece, so as to obtain the required geometry, size, accuracy and surface quality of the machine tools (except hand carried).

- Q: The main form of bit wear is the front wear Is that right?Shaper processing is a forming process? Yes?

- The main form of bit wear is the front wear Usually. But some high-temperature alloys, non-metallic grinding materials on the sub resistance wear equally quickly, for example, commonly used POM plastic

- Q: How about the metal cutting parameters?

- According to the workpiece machining allowance and machining requirements, selected cutting depth.

- Q: How is the cutting force calculated in a metal cutting unit?

- The power consumed in the cutting process is called the cutting power Pm (GB Po). The cutting power consumption for Fz and Fx power and Fy direction without displacement, so no power consumption.

- Q: What are the main factors that affect the quality of metal cutting?

- Influence of wear resistance on surface quality. A just finished friction pair two contact surface, the initial stage in the surface roughness of the peaks of the contact, the actual contact area is far less than the theoretical contact area in contact with each other, the Department has a very large unit of stress, the actual contact area generated at the shear plastic deformation and elastic deformation between shape and peak damage caused by severe wear.

- Q: What's the name of the machine that processes cutting tools?

- Welding tools such as cubic boron nitride and so on, and high frequency welding equipment.

Send your message to us

ZJ1300 x 3.0 Slitting line stainless steel cutting machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords