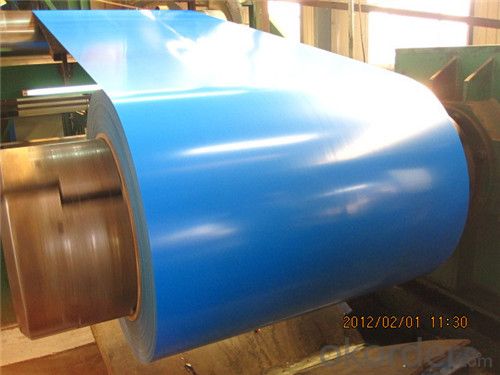

Z38 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z38 BMP Prepainted Rolled Steel Coil for Construction

Description of Z38 BMP Prepainted Rolled Steel Coil for Construction

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z38 BMP Prepainted Rolled Steel Coil for Construction

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3. Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle East, the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Applications of Z38 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z38 BMP Prepainted Rolled Steel Coil for Construction

Product | Z38 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z38 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different methods of tempering steel coils?

- There are several methods of tempering steel coils, including air tempering, oil tempering, salt bath tempering, and induction tempering. Each method involves heating the steel coils to a specific temperature and then allowing them to cool slowly to achieve the desired level of hardness and toughness. Air tempering involves exposing the steel coils to ambient air for gradual cooling, while oil tempering involves immersing them in heated oil. Salt bath tempering involves placing the coils in a bath of molten salt, and induction tempering uses electromagnetic induction to heat the coils. The choice of tempering method depends on the specific requirements of the steel and the desired properties of the final product.

- Q: i mean cor ten steel( rusted)

- Bill summed it up pretty quick and provided a link. For some reason you are focusing on the copper content when it really is insignificant in the overall picture of the sun hitting its surface. If you could elaborate more, maybe we could offer a better answer.

- Q: I want to build an indoor riding arena, should I go for Steel ones.

- Though okorder /.. You can also have a look!!

- Q: im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- Cold Steel takes a billet (read piece of metal stock) in high carbon steel, usually 1060 which is pretty good, and then heats it up and pounds it into shape with a pre-made form. This is called forging. Their swords are not Folded (the traditional manner) they are Forged. This is different from taking a piece of 1060 steel and just grinding it down into shape. The forging process creates very strong steel (not as strong as folding) that is much stronger than a sword or knife made from grinding a piece of metal down into shape. Cold Steel's stuff is generally thicker, but they are practical and with enough practice you can wield it just like a thinner lighter sword. Their weapons are what you would call battle ready meaning you could feasibly take it into a sword fight and use it like its more traditionally crafted counter part. The only downfall is its weight and and the fact that it isn't as strong as a folded steel sword, but it would do very well.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are several different coil packaging machine configurations used for steel coils, each designed to cater to specific coil sizes, weights, and packaging requirements. 1. Horizontal Coil Packaging Machine: This configuration is designed for packaging smaller steel coils. The machine typically consists of a conveyor system that transports the coil horizontally through the packaging process. It may include features such as automatic coil centering, wrapping, and strapping to ensure secure and efficient packaging. 2. Vertical Coil Packaging Machine: Suitable for larger and heavier steel coils, this configuration is designed to package coils in a vertical position. It typically includes a rotating arm or turntable that allows the coil to be rotated while being wrapped and secured with strapping. Vertical machines often have a higher throughput capacity and can handle coils of varying sizes and weights. 3. Ring Coil Packaging Machine: This configuration is designed to handle large and heavy steel coils. It consists of a rotating ring structure that surrounds the coil and moves up and down while wrapping and securing the coil with stretch film or other packaging material. Ring coil packaging machines can accommodate coils of various diameters and weights, making them versatile for different coil packaging requirements. 4. Eye-to-Sky Coil Packaging Machine: This configuration is specifically designed for steel coils that need to be packaged in an eye-to-sky orientation. It typically consists of a wrapping station that rotates the coil while stretch film or other packaging material is applied. This configuration ensures proper protection and stability during transportation and storage. 5. Eye-to-Horizontal Coil Packaging Machine: This configuration is suitable for steel coils that need to be packaged in an eye-to-horizontal orientation. It typically includes a conveyor system that transports the coil horizontally while stretch film or other packaging material is applied. Eye-to-horizontal machines can handle coils of varying sizes and are designed to provide secure packaging for easy handling. Overall, the choice of coil packaging machine configuration depends on factors such as coil size, weight, packaging requirements, and production throughput. Different configurations offer unique features and capabilities to ensure efficient and secure packaging of steel coils.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the irrigation system.

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- its used in lots of things (cutlery, bridges, engines), and riotinto have made a lot of money from it. and it's an alloy of iron with a bit of carbon in.

- Q: What are the safety precautions to be followed while handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Here are some safety precautions to be followed: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and hard hats. These items will protect you from potential hazards like falling objects, sharp edges, and chemicals. 2. Proper Lifting Techniques: Use proper lifting techniques to prevent strains and back injuries. Lift with your legs, not your back, and avoid twisting or jerking motions while handling the coils. If the coils are too heavy or awkward to lift manually, use mechanical lifting equipment like forklifts or cranes. 3. Secure Storage: Store steel coils in a secure and stable manner to prevent them from falling or rolling over. Use proper racks, shelves, or storage containers designed specifically for steel coils. Ensure that the storage area is clean, organized, and free from obstructions. 4. Handling Tools: Use appropriate handling tools like coil hooks, lifting clamps, or coil tongs to securely grip the steel coils. Avoid using makeshift or improper tools, as they can cause the coils to slip, resulting in accidents. 5. Secure Transportation: When transporting steel coils, ensure they are properly secured on the truck or flatbed. Use appropriate tie-downs, straps, or chains to prevent the coils from shifting or falling during transit. Follow all transportation regulations and guidelines to ensure safe transportation. 6. Awareness of Surroundings: Be aware of your surroundings and the presence of other workers or equipment in the area. Maintain a safe distance from moving machinery, forklifts, or other vehicles to avoid collisions or accidents. 7. Hazard Communication: Ensure that all employees handling steel coils are trained on proper safety procedures and understand the potential hazards involved. Display safety signs or labels to indicate the presence of heavy loads or hazardous materials. 8. Regular Maintenance: Regularly inspect and maintain equipment, such as lifting devices or storage racks, to ensure they are in good working condition. Report any defects or malfunctions to the appropriate personnel for prompt repairs. By following these safety precautions, you can minimize the risk of accidents, injuries, and damage when handling steel coils. It is important to prioritize safety in order to protect yourself and your coworkers in the workplace.

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- Sand casting useing silica sand was the classical method. Wood models called patterns made the cavity into which the metal was poured. Furnaces capable of melting iron and steel are not found everywhere. They are industrial machinery, not to be improvised. Some-one had better be very careful if he does get access to molten steel. There are some aspects of the process that are not intuitively obvious that can 'bite you' badly. Get at least some briefing from an experienced foundryman.

- Q: Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade was conceived when Kitiara and Sturm traveled together five years prior to the War of the Lance. Steel was then born at a woman named Sara Dunstan's house outside Palanthas. Kitiara let Sara raise him and when Sturm died Sara and Steel moved into the city of Palanthas. It's better explained in Second Generation by Margaret Weis and Tracy Hickman. Oh and I don't think the series is over commercialized I think that they could have done more with the original characters and the new characters. I'm also looking forward to the movie when it comes out next Autumn.

Send your message to us

Z38 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords