WPC outdoor wood plastic floor HDPE wood plastic material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000 m²/month

- Option:

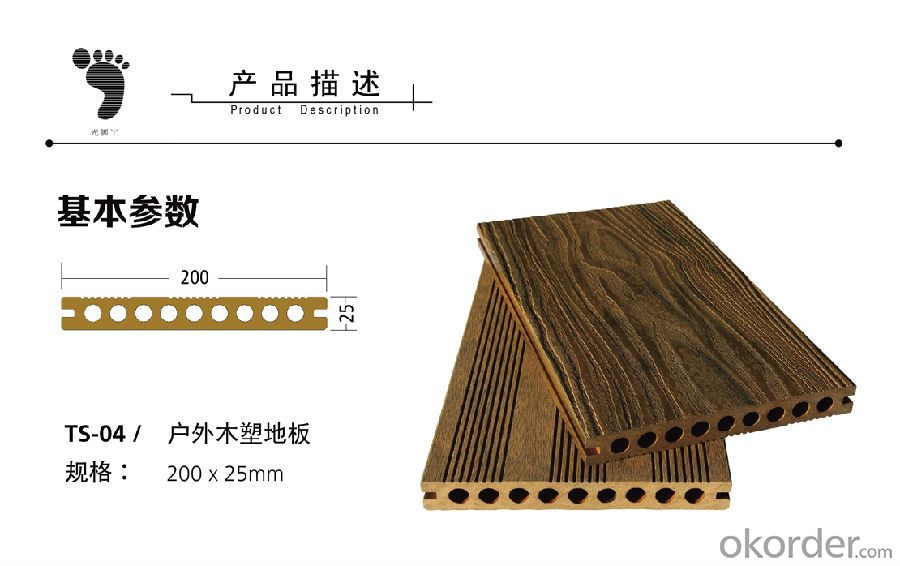

- 200*25mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

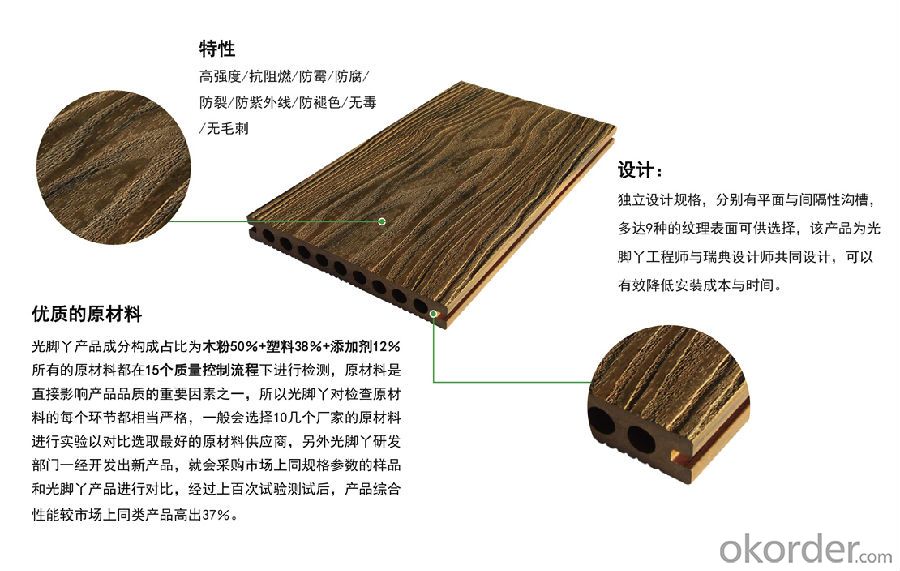

Product structure description:

Barefoot wood plastic is a combination of natural wood fiber and eco-friendly plastic polymer. It is a composite material. The manufacturing process is wood powder plastic and the required coupling agent and additives. It is fully mixed under high temperature and high pressure. Extruder extrusion is cooled. The barefoot control of the raw materials is extremely strict. The raw material of the wood fiber in the product is 80 mesh aspen wood powder is uniform and fine; the plastic polymer uses high density polyethylene; the US DuPont import auxiliaries; the first-class raw materials for the future The mechanical properties of the formed product provide a strong guarantee to ensure the stability of the product.

Main features of the product:

1. Strong bending strength (compressive ability) and high weather resistance:

We insist on the use of high quality HDPE (High Density Polyethylene), which has higher crystallinity than ordinary plastics on the market (low density, medium density) and thus exhibits higher strength. The process of rotation from the molten state to the solid state takes some time to eventually form crystals. HDPE undergoing this process will achieve higher shrinkage, 2-3 times the tensile strength of LDPE (low density polyethylene) and a compressive strength of 4600 psi. At the same time it has good heat resistance and cold resistance.

Weather resistance: good performance from minus 40 degrees to over 60 degrees

2, waterproof and moisture resistance:

3. Photooxidation and fading (anti-fading);

4. Effectively prevent oxidation and breakage, and have a long service life;

5, effective slip resistance;

6, no need to paint maintenance costs are low:

Get competitive prices from our large capacity. At the same time, the large capacity of the factory can be delivered quickly.

. No formaldehyde or harmful substances.

. Environmentally friendly products, the government vigorously promoted.

- Q:What is the meaning of strengthening the wear speed of composite flooring?

- What is the meaning of strengthening the wear speed of composite flooring?

- Q:This type of floor to hear someone say good. But the price is not expensive? More

- See what you are going to buy what level to send, such as simple decoration is not to buy too good to see if you want to decorate it

- Q:i have moisture on the floor all along one of my walls, about 6 or 7 boards have to be replace.the floor is just glued to the concrete slab, i went to homedepot to buy something to apply to the concrete or something to apply before installing the new floor, but the clerk told me i have to replace the whole floor, because there is nothing to apply before the floor and underlayments are too thick and the floor would not be leveled.Please can anyone help me with a solution so i dont have to replace 1000sq ft of floor.thank you

- You definitely do not have to replace 1000 ft2 of floor. The problem you are having is one of the reasons I did not go with the glued floor, I could not figure out how to vapor proof the floor from water. I would take out the boards that are bad and then asses the problem if you have to take out one more farther in to get a good place to bond to. I replaces a piece in the middle of a regular hardwood floor once and it takes a bit of time and patience to remove the bad piece without messing up the good ones that can be left. If you can leave the toungue or groove on the mating piece to match up to. Make sure the area is clean of the old glue. I would then get some of the cushion vapor barrier that you can buy and put it under the boards that are going over the moisture problem area. I do not think a coating would work. A 1/8 inch layer should not be noticeable and if it is go back and remove another board to lessen the slope of the floor. You could also use some 15 pound roofing felt to give a vapor barrier. Then when you glue back try to attach the new boards to the underside of the old boards so that glue does not come through. And note before you do this I would go to a wood flooring store and ask an experienced installer if you are going in the right direction. If you plead stupidity it is remarkable what you can learn from some of those old guys.

- Q:Is the composite floor insulator, if the person standing on the composite floor, one hand touch 220V FireWire, will electric shock more

- Composite floor is insulated, but in some cases the insulation effect is not so good, too many impurities

- Q:Composite wood floor cracking with what glue is good

- Floor cracking can generally change, if you have to fill it, it is best to find a piece of the same floor, with a small piece of knife, and then glue with 502 glue, you can

- Q:Is about to pay the election of the election of wood flooring, read a lot, do not know which floor good point, also please Supreme guidance! Question added: a good floor can also recommend Ha! Price slightly cheaper! Composite floor! More

- One of the top ten brands of laminate flooring: one of the top ten brands of flooring composite flooring: one of the top ten brands of composite wood flooring: one of the top ten brands of composite wood flooring: One of the top ten brands of flooring: Cicero flooring composite wood flooring one of the top ten brands: Parker floor composite wood flooring one of the top ten brands: Kenya floor composite wood flooring one of the top ten brands: Yangtze flooring composite wood flooring One of the top ten brands: macro resistance to harm the official car to mention the rules of the sea plate off the board of one of the top ten brands: Kyrgyzstan as the floor of the floor is like a solid wood do not know the complex you can go to see Thank you for the above composite floor

- Q:Can the composite floor be installed,

- Theoretically possible. Composite floor installation method 1. In the composite floor before the installation of the first check whether the door can be opened freely, if not, to the bottom of the door to a certain thickness, and then lay a layer of PVC over the ground film, so that can play a noise And the effect of moisture. 2. Place the first composite panel at the corner, the tongue and groove on the wall, with a wooden wedge leaving about 10mm of the expansion joints. 3. When installing the wall to the last board, take a full plate, place it in parallel with the previous tenon, set aside 10mm crossed on the wall end, install until the end of the line, if the remaining material length For 40cm, you can keep to the next line to use. 4. From the second line, the inside of the tongue and groove to be evenly coated with the floor of the special glue (the first line does not glue), the floor is fully installed, and then wet cloth or plastic scraper in time to spill the glue off. 5. Tighten the floor with a hammer and a wooden last. 6. After the first two lines, in a timely manner with a rope or ruler to calibrate. 7. left the last line of time, to take a piece of the whole board, on the already installed on the floor, up and down alignment, and then take another floor, on the board above, one end of the wall, and crossed, along the line Saw, this is the width of the floor required. Installed to the last line of the board, put the wood last block, the use of special fasteners will be squeezed into the floor, after installation 2 hours, the withdrawal of wood last.

- Q:What is the height of the solid wood flooring and the composite floor after laying? How much is the solid wood floor?

- Solid wood flooring is generally 18mm, strengthen is 12mm, come and go is not the most important difference is that solid wood to shop keel, the difference is big

- Q:Has anyone worked with Bostik EFA for installing an engineered floor? Is EFA better than Bostik Best?

- Bostik Best is the premium adhesive in the wood flooring industry, also the most expensive. You should look at Mapei 980, or Taylor MS Plus adhesives for a lower cost option.

- Q:Home underground water pipes leaking, to the composite floor valve crisp Juyi wrong with nitrogen hair open repair, the floor is a card slot, not very good demolition, but also afraid to break the floor, and ask how to open better The (To open the location is in the bathroom door 40cm place) Question added: I would like to split from the room at the stalls try, their own should pay attention to what? More

- Home underground water pipes leaking, to the composite floor valve crisp Juyi wrong with nitrogen hair open repair, the floor is a card slot, not very good demolition, but also afraid to break the floor, and ask how to open better The (To open the location is in the bathroom door 40cm place) Question added: I would like to split from the room at the stalls try, their own should pay attention to what? More

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC outdoor wood plastic floor HDPE wood plastic material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000 m²/month

- Option:

- 200*25mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords