WPC Door Frame Looks and Feels Like Natural Wood

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> Why choose WPC decking?

Natural colour

Resistance to water, rot and crack

Guaranteed to last

Low maintenance

Beautiful and broad range of finish

3> What are the main kinds of WPC currently?

Door frame

Wall panel

Skirting

Wardrobe door panel

Product Description

4> Specification of WPC?

Characteristics | WPC | Wood |

Moisture Resistance | Waterproof | Water absorptive |

Rot Resistance | Antisepsis | Rot except special treating |

Split Resistance | No Cracked | Cracked by weathering effect |

Distortion Resistance | Almost no Contraction/expansion | Distorting effected by chang of moisture and temperature |

UV Resistance | High Grade UV Resistance | Easily effected by UV |

Fading Resistance | Almost no | Easy to fade |

Outdoor adaptability | Great | Only few of treatedowood adaptive |

No need painting | No need | Need paint periodically |

Durable/longevity | > 8-15 years | < 3 years< span=""> |

Various Configuration | Extruded via various mould | simplex |

Environment Effect | Recyclable 100% | Consume woods |

Company Information

5> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

Preferential payment terms

good and reasonable price

quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

professional team for CRM order processing & QA & logistics

global logistic database, originated from Dubai

Packaging & Shipping

6> How to buy and concerned terms

MOQ – 800m per item

Lead time—2 weeks

Departure port—Shanghai

Package-- PE film, carton box or 2pcs.bundle, treated pallet

7> Certificates and Quality guarantee

Certificates – CE&ISO 9001 complied

Warranty—10 years

Quality guarantee—test report for each order under the strict management system

- Q: Doors and windows with a nail installed in the cement brick, is it necessary to have to nail on the cement brick, or as long as there are a few pieces in the cement brick, the other can be nailed to the red brick? Do you only need to nail on the concrete? More

- Now some local standards and acceptance specifications have been banned with a nail fixed window frame, whether it is concrete or brick wall. Drill holes should be used for expansion screws.

- Q: Aluminum alloy doors and windows frame installation, the box and the wall must be left between the joints? If the window frame on the mouth size is too small, direct contact with the wall, you can? Question added: is now in the installation of doors and windows, the box has been safe , Not hit the bubble. I would like to ask is not a small hole, no way to play bubble agent, which can also be through acceptance? Or must be demolished to re-hole, leaving a certain gap to play bubble? (Oh, I was a student in the internship, some uncertain is not through the acceptance.) If the wall and the box is not flexible connection, then what may lead to the consequences? More

- Did you mean that you first grind the wall? If it is according to national standards: between the box and the wall must stay 5 mm seam. But the national standard is the minimum standard, Party is the highest standard. Treatment is a total of 6 mm on both sides of the seam, marked with styrofoam can be.

- Q: The installation method of color steel activity room

- ① Before installation, the construction unit shall check the product certificate, design document and pre-assembly record of the component, and check the size of the recording component. Deformation of the steel structure, defects beyond the allowable deviation should be processed. Before installation, should be prepared in detail the measurement and correction process, thick steel plate welding should be installed before the simulation of the product structure of the process test, the preparation of the corresponding construction process. On the assembled roof truss should be a certain degree of arrogance. ② steel structure hoisting in place, the component positioning axis, elevation and other design requirements of the control point to do a good job marking, the quality of the lifting connector for welding before the inspection. Installed temporary support and steel cable to make steel roof truss in the construction process safe and stable. ③ steel installation, the construction unit should be submitted to each component after lifting the elevation size, welding, painting, etc. were submitted to the supervision and acceptance.

- Q: Red TV background wall, white wall, juvenile window frame with what color curtains nice, living room, bedroom, son room

- Curtain color as much as possible in the same color to find light, such as large windows with pale pink, small windows can be appropriate than the color deep. Or select the point of contrast is also OK, a small area, mainly used to embellishment.

- Q: What are the key points for the production and installation of wooden doors and windows?

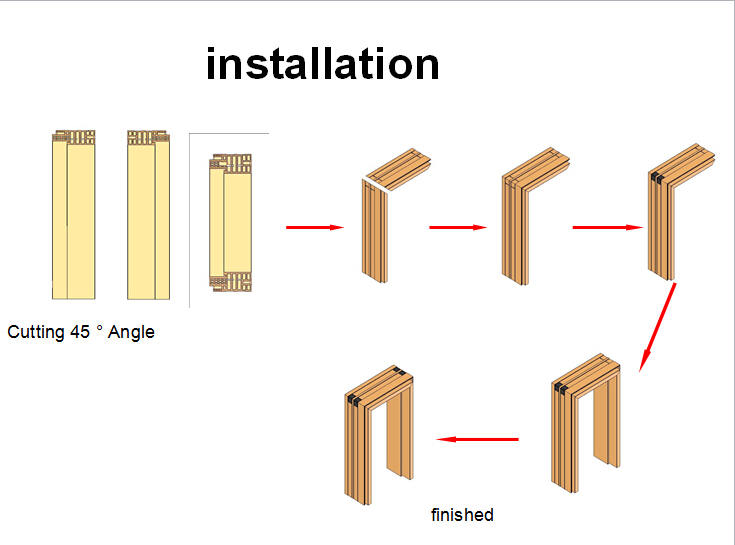

- 2, the first fixed hinge side, to be close can not have a gap, up and down and left and right vertical, with screws or gun nails fixed; 3, door sets and the door frame pressure can not exceed 0.3mm, the line in the saw 45 ° angle when the corner to be straight, if burr, sandpaper sanding after the fight; 4, after installing the door, check whether the two sides are equal, the door is too large or too small , Some to open and close the page must be the first amount of accurate size, before processing, assembly page when the screw to play straight, lock to be firmly flush; 5, good product protection.

- Q: Why do wooden doors and windows installed is the first installation of windows and doors after plastering and metal doors and windows and plastic doors and windows is the first plaster into the mouth after the installation

- This is not absolute, wooden doors and windows in general size is relatively fixed, the first legislation of the practice is more common, two metal and steel doors and windows larger size, can be processed in the factory production, so the practice of more

- Q: Now the general situation of the site is: the floor is the floor tile floor, doors and windows are wooden doors and windows, plaster has been in the door window when the mouth of the box and other boxes installed after the mouth. Down, do not know how to run well, mainly the door frame of the problem. Now is the first installation of doors and windows box and then shop tiles, or the first floor tiles and then install the door frame? If it is the latter, or do not keep the door of the floor tiles, such as the door frame after the installation, after the package? The first dry this, stuck here, the teachers to help, how to do down What experience to tell the little brother, not Sheng grateful. More

- First install the door frame, in the brick door frame is not installed first, then the door is easy to deformation off, the first installation of the door frame can effectively prevent the door and door frame deformation off the door of the situation, the door height in the production of the thickness of the brick Stay in the minus 1cm, to avoid the door core hanging feet friction floor tile.

- Q: The installation of the horizontal lines, vertical lines and out of the line, respectively, what is the use of what in the end

- 1, aluminum doors, window frame approach, check the horizontal line, draw vertical lines, entry and exit lines, window frames, holes on the bit, clean the hole. 2, oblique wood wedge fixed window frame, correction, nail fixed iron feet, check. 3, mortar or fine concrete foot iron feet. 4, iron foot mortar dry solid, remove the wooden wedge, powder outdoor hole. 5, note the blowing agent, outdoor playing the first degree of silica gel. 6, window frame mortar sealing box, rub real, take the pulp. 7, door and window frame inside the silicone, outdoor playing second degree of silica gel. 8, installation box fan. After installation, the connector, the blowing agent to conceal acceptance. The vertical and horizontal of the doors and windows to measure the actual volume, so that the installation quality to meet the requirements. In the installation of aluminum doors and windows, generally according to the following procedures for acceptance: the installation of pre-acceptance doors and windows openings, installation doors and windows frame, check the door and window frame, playing expansion agent, outdoor first silicone, acceptance expansion agent, silicone, , Acceptance hole, painting, playing silicone, acceptance of silicone, doors and windows fan installation, doors and windows as a whole acceptance, water test. Doors and windows all installed, but also to spray test to check the leakage of doors and windows.

- Q: How to deal with waterproof coatings on aluminum windows

- With a rosin perfume just fine! Give you a picture to see!

- Q: Rough leveling how to use?

- Before the construction should measure the wall to determine the thickness of the wall leveling layer, if the wall flatness is very good, you can reduce the leveling layer thickness, do not have to worry about whether the material can meet the strength, because the Pratt thick rough construction thickness from 5mm To 50mm are suitable. Determine the thickness of the leveling layer should be in the wall for the elevation of the line, the spacing between each tendons in the 1.2-1.5m or so, according to the experience of construction workers to determine the vertical arrangement of tendons from the corner position in turn arranged. Prades without formaldehyde rough leveling is a one-component powder products, according to the requirements of the amount of water (about 45%) can be used evenly stirred. Base surface requirements solid clean without powder, no sand, no peeling, surface attached debris, oil should be clear, the hole should be filled in advance. Check whether the doors and windows frame is securely connected and fill the gap between the door frame and the wall with a good "paste". Adjust the "slurry" should be within 30 minutes on the wall, in the grassroots first thin scraping again, the purpose is to make the material and the grass-roots contact between the full. And then approved on the wall enough to adjust the "slurry" with a 2m long by a one-time scratch can be. Indoor pillars, the location of the wall angle should be increased Prades Corner, the height of not less than 2m.

Send your message to us

WPC Door Frame Looks and Feels Like Natural Wood

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords