Wood Plastic Decking!/Friendly and comfortable outdoor WPC plank/Hot!

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Wood Plastic Decking Description

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Wood Plastic Decking

WPC/PVC outdoor decking, indoor decking, soft pvc decking, wall panel, handrail, arbor,stand colum, tray panel, keel, grilling, connection, horny line, great wall panel, buckle ceiling, square pillar, door frame, door line, door mullion, PS foam profile, Accessoreis

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

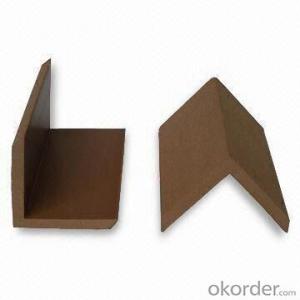

三.Wood Plastic Decking Images

四.Wood Plastic Decking Specification

Name | Wood Plastic Decking |

Size | W*H=145*30 mm |

Length | 2200mm, 2900mm, 5400mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Wood Plastic Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Performance requirements for plastic flooring

- Including the appearance quality, comfortable, water resistance and other properties.1, appearance quality. Including color, pattern, off Ze, flatness and crack, etc.. In general, the distance from the 60cm, the visual can not be uneven, Guan Ze and color unevenness, cracks and other phenomena.

- Q: Wood floors and wood floors in the outdoor anticorrosion materials?

- Wood floors and wood floors two anti-corrosion materials have advantages, is also a lot of people in the use of. Wood floor appearance than the wooden floor was neat rot, but somehow anticorrosive wood floor is pure wood, wood is the feeling of wood floor can not be replaced. If it is very modern, choose plastic wood floor, the contrast with the rotten wood floor.

- Q: Can the plastic stair step of the cement in the home spread the plastic floor

- Depends on the smoothness of the stairs, if the surface has a lot of pit pit bag is not installed directly

- Q: Composite floor plastic sheeting down the impact of heat

- The floor of the thermal resistance value is 5 times the floor tile, the same inlet temperature, the room floor is better than low floor tile room above 3 degrees, your home is normal, remove the film under the floor as not useful, the fundamental reason is that your home water temperature is too low, usually the floor room, into the water temperature above 50 degrees, up to 55 is will be very hot. I estimate your home water temperature will not reach 45 degrees will appear this situation. And warm design relationship

- Q: Classroom platform shop plastic floor with no need to do self leveling?

- The floor is made of civil leather, paper and leather, the life of 1 to 2 years, not fireproof material, the price of 5 yuan to 15 yuan of 1 square meters, while the PVC floor is pure engineering material and plastic floor, PVC, life of 6 to 20 years, fire prevention materials,

- Q: Technology of plastic floor

- 6, the wall and the ground Yin and yang angle of 90 degrees, the Yin and yang angle into a straight line, the ground requires flat pressure.7, check whether the ground shell, sand and protruding concave convex, cracks and other phenomena.

- Q: What is the material of the plastic foam plate

- The general use of four roller mill factory plasticized PVC, after the pressure of the surface is smooth and smooth, cooling after the edge of the strip is the product

- Q: Warm the house, with plastic floor?

- The varieties and patterns are very much, the price from tens of dollars to several hundred dollars, I give the child the choice is a 85 yuan, to the living room, bedroom and other choice is a 160 yuan, children room floor is the cartoon, colorful and beautiful, the other room is wood Road, in fact I think the shop is on the grade, and not before the kind of floor leather appearance, many people go to my home, feel very high-grade, style, and home decoration environment is very fit. And because the floor like wooden floor is a mosaic, but a whole, so there is no seams, children at home often pee or water ah, ah and milk on the floor, wipe with a rag on the line, do not have to worry about it will penetrate into the floor.

- Q: PVC plastic flooring should be how to pave the road, want to shop this floor, but do not know PVC plastic floor price per square meter of stone? Tell me what the trouble!

- For different horizon: 1, cement: Horizon must clean wet (if it is to be painted after the paint is dry), all cracks and holes with suitable fillers (such as gypsum). 2, wood floor: to ensure that the original floor clean, clean, no glaze, no wax, no oil, and firmly stick to the ground, the filling of all cracks and holes with the appropriate (such as gypsum). 3, PVC floor: remove all dirty oil or wax floors, must not be laid on the soft plastic or rubber floor, the floor will be removed or covered with a layer of three plywood, and the filling material is suitable for all cracks and holes (such as gypsum).

- Q: 3dMAX plastic flooring how to paste like tiles

- To glue the words similar to the Philippine Neal reflection, the middle part of the reflection is slightly low, high light slightly higher blur, you can set a little bump map

Send your message to us

Wood Plastic Decking!/Friendly and comfortable outdoor WPC plank/Hot!

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords