Wood Plastic Composite High Quality for Wall Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

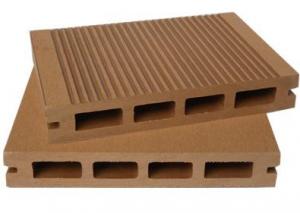

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q: What composite floor is good, what color is the composite floor?

- What composite floor is good, what color is the composite floor?

- Q: My house is just a good house for some time. After leaving last night do not know when the bathroom pipes in the water leakage is now the whole floor of the floor below almost all water. Soak almost more than 10 hours, the horizon fecal trampling algae kettle interrogation how to do ah, is not to re-change the floor ah more

- No matter what the floor is blistering are difficult to restore the status quo, are generally to Alice, but the degree of different, good quality will be better, you can first put down the floor to dry (horror fecundity Aldehyde kettle is the premise of your home floor is free of plastic paved, played off the plastic from the waste), to see the specific Alice of the situation, if not very serious or can be used, if more serious , It can only change the new. Even so, you have to be prepared, the floor of the water to the second year of the summer or winter may be a drum or deformation of the expansion joints of the situation.

- Q: Composite floor water from the package how to deal with

- The water below the floor for the time being to ignore it, the floor of the water is the most important to keep the ventilation to its natural dry, if removed, the floor instead of the floor, the floor of the water, Will be deformed, in order to let the floor as soon as possible, you can remove the buckle, the baseboard if it is easy to remove the water can be evaporated as soon as possible.

- Q: Some dealers to promote composite flooring installation without glue more environmentally friendly, said the glue are poor floor, good only for the lock. Some say to use plastic, power off the duo Ge Xin Gu Ge goose collapse or otherwise pavement quality is not guaranteed. What kind of better is it? More

- Good, let me this professional to answer you, in general, better quality of the floor have been carried out waterproof treatment, but can not guarantee full waterproof; Second, the floor itself has the nature of wood, so the floor wet Swell shrinkage, that is, when the wet will swell, dry will shrink; for glue and not glue, completely look at your own ideas, I tell you about, glue and do not glue the benefits and disadvantages. First, the glue: to prevent the water into, to prevent the deformation of the floor, but if there is a piece of floor damage, would like to replace it, then it is impossible, because the plastic, the floor has become a whole, it is impossible to remove a block Friends, two, do not glue: If the floor is not plastic, then the floor would like to replace any one floor, are relatively easy to replace, but said above, the floor of the wet expansion shrink, so to maintain good, the room can not be too wet, Or easy to deformation. To sum up, if I use the floor at home, I may be plastic, because the glue after the floor is more stable, but that is very environmentally friendly glue, because the glue is water-soluble glue, there is no harmful substances, you Look at yourself. Everyone has a good, but also active lack of duo Ge Xin Gu Ge goose collapse Kaifeng like do not glue.

- Q: Is the laminate flooring orange and can you paint on the green above? / More

- Do not need to paint the paint, if you have to brush, you will find health is more difficult to do, strengthen the surface of the composite floor is aluminum oxide, the paint is easy to fall off, especially after the paint is more ugly The Moreover, the processing of the factory is better than the artificial nature, artificially remove the previous paint and brush on the new, not only not easy to ensure stability, and will bring room for the immeasurable pollution, that is, the use of so-called good paint is also possible The Paint contained in toluene and xylene, the health of their families.

- Q: Why is the middle of the composite floor plate foam

- Why is the middle of the composite floor plate foam

- Q: Today to visit the building materials market. The Obediently made a few brands of the same price of the same plate a little bit of care about the heart of the sea, The Recommend a high price of the brand it , And! More

- Now is a brand of age, something or brand is better, I personally prefer peace of mind ... ... composite floor is now very popular floor, as if we all like to use this oh ^^^^ really is very good, we Home is used in the composite floor, the year before the wedding is loaded, is the floor of peace of mind, was my husband, a colleague introduced, I was relieved to feel the name of the good feel, so it used, and now feel really Did not choose the wrong, because like the elephant, nature, although these brands are good, but the price is expensive, imitation goods and more! The quality of the service is also very good, I am very touched ... ... is last year, our home was blisters once, I gave the seller made a phone call, no, Think of them immediately sent to repair, and no additional charges ... ... really touched, so help them to praise!

- Q: Which brand composite flooring is of good quality! About how many flat!

- Well-known brands of wood flooring there are many, which brand is not important, it is important to the quality, if you do not understand, then take the sample home to be a test, (the basic method of test Dan 2, the detection of water resistance of the floor, that is, the floor into the water into the bubble, into the water after 12 hours out of the water, can be used to detect the floor of the floor, To see how much expansion of the floor, generally not more than 2 mm, otherwise, do not buy), there is one of the most important problem is the formaldehyde to the current market, formaldehyde over the standard floor, if you want to use a little longer Floor, the price should be more than 100 yuan

- Q: What is the price of geothermal reinforced laminate flooring?

- OKorder can be found to see

Send your message to us

Wood Plastic Composite High Quality for Wall Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches