wood pellet mill wood pellet making machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wood pellet machine, is also named wood pellet making machine, sawdust pellet machine, power pellet machine, straw pellet machine, biomass pellet machine, rice husk pellet machine,organic fertilizer pellet machine, feed pellet machine and straw coal making machine.

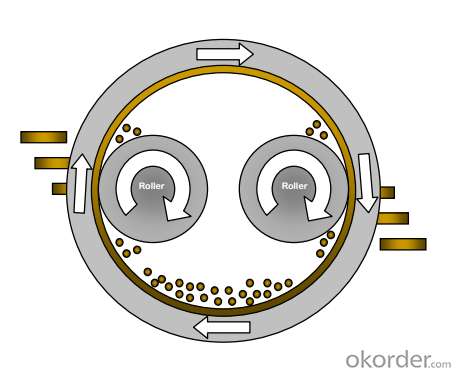

The new wood pellet machines solve the problems effectively of biological crude fiber granulating hardly and less effective. The main part works with high standard overloading reducer, which can ensure the power transmission efficient, stable, low noisy and longer lifespan by choosing high quality bearings. Ring die adopts the quick-release anchorear type, feeding conveyor adopts inverter to adjust the speed to feed more evenly. The new wood pellet machine adopts international advanced manufacturing technology, “roller wraps” is made of high alloy wearable material, this models have characteristics of unique design, reasonable structure, high efficiency and long lifespan.

Features:

1. High efficient, centrifugal, high pressure power, suitable for quenchless materials

2. Low wear rate, long lifespan for ring die and roller wraps

3. Rollers are with automatic lubrication system, can work continuously

4. The ring die adopts vertical type, can feeding upright with high efficiency, and is good for dissipating heat.

5. Long working life for ring dies: being made of alloy steel with special processing technic, having hard and wearable surface and tough inner part, having high impact toughness at low temperature.

6. Cost-effective: on the basis of the similar equipment, improving the technological content and function of machines. Full consideration on the price for the affordability of wide users.

Suitable range and application:

The product is applied to materials with low adhesiveness and quenchless. For example, rice husk, sunflower husk, peanut shell, fruit shell; branches,tree trunk,tree bark, kinds of wooden waste; kinds of crops straw; rubber,coal ash and other chemical raw materials. Applied in animal feed factories, wood processing plants,synfuel plants, fertilizer factories, chemical factories, etc, they are the most ideal compression molding equipment with small investment, quick effect,risk-free.

- Q: When can I get the certificate from the feed processing maintenance certificate

- 4, technicians (1) after the professional qualification certificate of the professional senior, continuous work in this profession more than five years, (2) obtain the advanced professional qualification certificate, professional engaged in the professional work eight years in a row. (3) of the professional qualification certificate of the professional senior senior vocational school graduates and college degree or above, majored in this professional and graduate, engaged in the professional work with 2 years in a row.

- Q: What is the mechanism of feed machinery

- Feed expander machine can be used for the expansion of raw materials such as corn, soybean meal, bean meal, rapeseed meal and cottonseed meal. Expander, feed expander,

- Q: What equipment does the production of feed premix need?

- 3, packing machine. For finished packaging. After mixing and mixing, the product is piped to the packaging machine for packaging. Measuring equipment. Including electronic balance, electronic balance and platform scale, used for weighing materials, semi-finished products and finished products. The above production equipment can meet the production of feed premix.

- Q: I want to open a private chat factory in a county-level city around the provincial capital.

- I have been in the feed factory for many years, the benefit is best is the pig, rabbit feed is the last chicken feed, do you do the whole price or the concentrated material? Knowing what you want to do with your plan is how much money you want to get out of the device. Be sure to be built in the traffic is the best place that has the railroad, your product cost ability is low otherwise have no competition ability, I don't love typing you can call to consult me

- Q: What kind of equipment do you need to start a cattle and sheep feed factory?

- If you do it all by hand, don't ask for production, just buy some of the simplest Labour tools, and you want to go to a blender anyway?

- Q: The price of complete equipment for large animal feed machinery

- The structure is simple, the whole steel frame type, the floor type three kinds. Integral steel frame type is compact, modelling is beautiful air; Floor type use, maintenance is convenient.

- Q: Method of crushing of feed mill

- The basic method of crushing is the process by which external forces overcome the cohesion and fracture of the intermolecular forces. Breaking: it mainly depends on the high-speed moving parts, the impact is the cracking, the method productivity is high, the heat is less, the ash powder is less suitable to the additive brittle material.

- Q: I want to run a small pig feed processing plant in the countryside, I don't understand the technology can do?

- At least 80,000 yuan, the equipment has a blender mixer for the machine

- Q: What equipment does a complete small feed processing plant need?

- A set of small feed units is a complete set of equipment. Other auxiliary equipment: belt loader, fan. Basically you don't need any other equipment.

- Q: What equipment does the feed factory need

- If you produce 10 tons of production each day, the 10 tons of raw materials will cost between 50 and 80,000 yuan. If have enough money, I suggest that you first do agent, selling other people's feed, open points belong to your market, after 3 ~ 5 years, have the experience and accumulation, the proposal to open a new factory to do not too late.

Send your message to us

wood pellet mill wood pellet making machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches