Pellet mill pellet-fodder expander wood pellet mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wood pellet machine, is also named wood pellet making machine, sawdust pellet machine, power pellet machine, straw pellet machine, biomass pellet machine, rice husk pellet machine,organic fertilizer pellet machine, feed pellet machine and straw coal making machine.

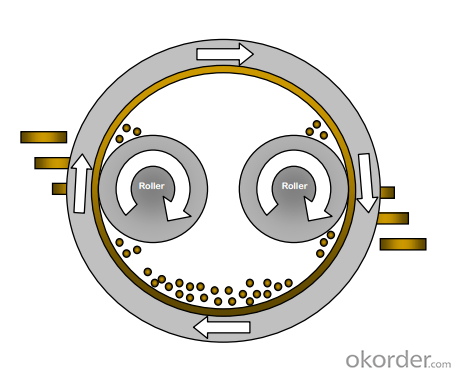

The new wood pellet machines solve the problems effectively of biological crude fiber granulating hardly and less effective. The main part works with high standard overloading reducer, which can ensure the power transmission efficient, stable, low noisy and longer lifespan by choosing high quality bearings. Ring die adopts the quick-release anchorear type, feeding conveyor adopts inverter to adjust the speed to feed more evenly. The new wood pellet machine adopts international advanced manufacturing technology, “roller wraps” is made of high alloy wearable material, this models have characteristics of unique design, reasonable structure, high efficiency and long lifespan.

Features:

1. High efficient, centrifugal, high pressure power, suitable for quenchless materials

2. Low wear rate, long lifespan for ring die and roller wraps

3. Rollers are with automatic lubrication system, can work continuously

4. The ring die adopts vertical type, can feeding upright with high efficiency, and is good for dissipating heat.

5. Long working life for ring dies: being made of alloy steel with special processing technic, having hard and wearable surface and tough inner part, having high impact toughness at low temperature.

6. Cost-effective: on the basis of the similar equipment, improving the technological content and function of machines. Full consideration on the price for the affordability of wide users.

Suitable range and application:

The product is applied to materials with low adhesiveness and quenchless. For example, rice husk, sunflower husk, peanut shell, fruit shell; branches,tree trunk,tree bark, kinds of wooden waste; kinds of crops straw; rubber,coal ash and other chemical raw materials. Applied in animal feed factories, wood processing plants,synfuel plants, fertilizer factories, chemical factories, etc, they are the most ideal compression molding equipment with small investment, quick effect,risk-free.

- Q: What is the mechanism of feed machinery

- Feed expander machine can be used for the expansion of raw materials such as corn, soybean meal, bean meal, rapeseed meal and cottonseed meal. Expander, feed expander,

- Q: What kind of equipment is needed for the processing of 100 fragrant pulp for cattle feed

- The raw material processed by high water content is dried, dried and dried.

- Q: What kind of equipment do you need to start a cattle and sheep feed factory?

- If you do it all by hand, don't ask for production, just buy some of the simplest Labour tools, and you want to go to a blender anyway?

- Q: The price of complete equipment for large animal feed machinery

- The large and medium-sized whole feed equipment adopts the computer to measure the ingredients automatically, the accuracy of the ingredients is good, the mechanization and the automation degree are high. The design standard complete feed project is the best technology plan, closely following the domestic and international development trend.

- Q: Method of crushing of feed mill

- Broken: using two of the original disc, engraved with the stiffness of the tooth surface to friction and the fracturing of feed, its advantage is the manufacturing cost is low, the power is small, feed temperature is higher, defect is grinding out powder, finely degrees is not easy to control. Suitable for processed plastic material. Crushing: 3, the use of two smooth surface roller, in the same relative rotational speed, the feed crushed, often used for flattening the barley feed, such as feeding newborn piggy as other animals.

- Q: I want to run a small pig feed processing plant in the countryside, I don't understand the technology can do?

- At least 80,000 yuan, the equipment has a blender mixer for the machine

- Q: Feed plants open what feed equipment

- Production from cows need delivery before and after birth, calf back before and after the island into adulthood cowshed, youth shelter, mother into the barn and milking parlour build, such as, as far as possible do streamline, and mutual interference, convenient production, deal with their relations, meet the needs of the production of the dairy life, and at the same time considering the barn to sports venues, diagnosis and treatment, health care facilities to cows to create a quiet and comfortable living environment. Even: beginning from the cow lie to gather the food, drinking water, the movement to the environment temperature, moderate, air quality, lighting control omni-directional design, provide services to the health of the dairy life.

- Q: What equipment does a complete small feed processing plant need?

- A set of small feed units is a complete set of equipment. Other auxiliary equipment: belt loader, fan. Basically you don't need any other equipment.

- Q: What is the price of a machine that processes straw feed? Specifications? The more detailed, the better

- High density (0.7-1) can be 20-30 times higher than the original straw, which can be easily circulated and stored. 2, good palatability, straw produced in the process of extrusion production of high temperature, 100 ℃, slightly paste fragrance, the animals love to eat, feeding rate can reach 100%. By being ripe, it is good for digestion. High temperature and high pressure, insect sterilization, no additives, are pure natural green feed, feed and feed safety. It is not flammable, it is stored for long periods.

- Q: What equipment does the feed factory need

- If you produce 10 tons of production each day, the 10 tons of raw materials will cost between 50 and 80,000 yuan. If have enough money, I suggest that you first do agent, selling other people's feed, open points belong to your market, after 3 ~ 5 years, have the experience and accumulation, the proposal to open a new factory to do not too late.

Send your message to us

Pellet mill pellet-fodder expander wood pellet mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches