Wide Aluminum Coil for Radiator - Grade Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Coil Grade for Radiator Description:

They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminum Coil Grade for Radiator :

1) Radiator

2) Condenser

3) Insulation Material

4) construction

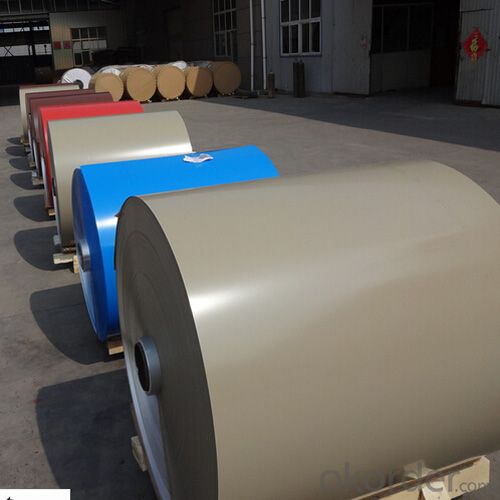

3. Aluminum Coil Grade for Radiator Images:

4. Aluminum Coil Grade for Radiator Specification:

Products | Alloy | Temper | Thickness(mm) | Width(mm) | length |

| Aluminum coil | 1XXX, 3003 8011, 3105 | H14, H16, H18, H24 , O | 0.08mm-6.0mm | 200mm-1500mm | 500mm-4000mm |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Pretty please can someone show me the steps on how to do this one?Calculate the mass in grams of iodine (I2) that will react completely with 43.7 g of aluminum (Al) to form aluminum iodide

- easily the guy earlier me did it precise yet made a mistake at one ingredient 0.07 mole is the # of moles of Al which desires to get replaced to moles of product, and then returned to come across mole of iodide. as quickly as thats stumbled on then you quite can use the MW to alter it to grams.

- Q: Do you have an aluminum coil first? Is there an aluminum plate?

- Yes, all aluminium sheets are made of aluminium rolls after slitting. The general process of aluminum plate production is: aluminium ingot - aluminum water - casting roll - aluminum roll ---- aluminum plate [Ji'nan excellent aluminum industry]. Welcome to visit.

- Q: Can aluminum coils be used in marine environments?

- Marine environments can indeed utilize aluminum coils. Aluminum is a favored option for marine applications because of its exceptional resistance to corrosion. When exposed to air, it develops a protective oxide layer on its surface, which aids in halting further corrosion. In marine settings, such as those with saltwater or high humidity, this oxide layer proves particularly effective. Moreover, aluminum's lightweight nature facilitates easier handling and installation in marine applications. Additionally, it possesses remarkable durability and can withstand challenging conditions, including exposure to UV rays and extreme temperatures. Consequently, aluminum coils find common usage in diverse marine applications, including boat hulls, shipbuilding, offshore structures, and other marine equipment.

- Q: How do aluminum coils contribute to the corrosion resistance of products?

- There are several ways in which aluminum coils contribute to the corrosion resistance of products. Firstly, aluminum itself is highly resistant to corrosion, thanks to the formation of a natural oxide layer when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and corrosion. When aluminum is shaped into coils, it offers additional benefits for corrosion resistance. The coil form allows for a more even distribution of the material, ensuring that the entire surface area of the product is covered by the protective oxide layer. This helps to prevent localized corrosion and ensures a consistent level of corrosion resistance throughout the product. Furthermore, aluminum coils can be coated with various protective coatings or treatments to enhance their corrosion resistance even further. These coatings provide an extra layer of protection against environmental factors like moisture, chemicals, and UV radiation, which can speed up corrosion. Additionally, aluminum coils are often used in conjunction with other materials, such as galvanized steel or stainless steel, in products. These combinations, known as bimetallic or trimetallic products, utilize the different properties of each material to enhance corrosion resistance. For example, the aluminum layer can act as a sacrificial anode, corroding preferentially to protect the underlying material from corrosion. To summarize, aluminum coils contribute to the corrosion resistance of products through the inherent corrosion resistance of aluminum, the even distribution of the material in coil form, the possibility of applying protective coatings, and the use of bimetallic or trimetallic combinations. These factors ensure that products made with aluminum coils have a longer lifespan and are better protected against corrosion in various environments.

- Q: What is the typical thermal conductivity of aluminum coils?

- The typical thermal conductivity of aluminum coils is approximately 205-220 W/mK. Aluminum is known for its excellent thermal conductivity, making it a popular choice for heat transfer applications such as in HVAC systems, refrigeration, and heat exchangers. The high thermal conductivity of aluminum allows for efficient heat dissipation and transfer, ensuring optimal performance and energy efficiency in these systems.

- Q: What is the maximum coil width available?

- The maximum coil width available depends on various factors such as the manufacturing capabilities of the specific supplier or manufacturer. However, in general, coil widths can range from a few millimeters to several meters. The maximum width is typically determined by the type of machine used to produce the coils and the size limitations of the raw materials being processed. It is recommended to consult with specific suppliers or manufacturers to determine the maximum coil width available for a particular product or application.

- Q: Are aluminum coils suitable for high-gloss applications?

- Yes, aluminum coils are suitable for high-gloss applications. Aluminum has excellent reflective properties and can be easily polished to achieve a high-gloss finish. Additionally, aluminum is lightweight, durable, and resistant to corrosion, making it an ideal choice for a wide range of high-gloss applications such as automotive trim, signage, and decorative elements.

- Q: Can aluminum coils be used in the production of aluminum composite roofs?

- Yes, aluminum coils can be used in the production of aluminum composite roofs. Aluminum coils are commonly used in the manufacturing process of aluminum composite roofs due to their durability, lightweight nature, and ability to resist corrosion. The coils can be easily formed and shaped into the desired profile for the roof, ensuring a seamless and aesthetically pleasing finish. Additionally, aluminum offers excellent thermal and sound insulation properties, making it an ideal choice for roofing applications. Its high strength-to-weight ratio also contributes to the overall structural integrity of the roof. Overall, using aluminum coils in the production of aluminum composite roofs provides a reliable and long-lasting roofing solution.

- Q: What are cold rolled aluminum coils and hot rolled aluminium coils, what are their respective features?

- Each has its advantages and disadvantages.Cold rolling mainly deals with non thermal strengthening of sheet metal. Generally, the surface requirement is relatively high, and the ultra-thin materials such as single zero foil, double zero foil and so on can only be rolled by cold rolling.

- Q: How do aluminum coils perform in extreme temperatures?

- Aluminum coils display remarkable performance in extreme temperatures, renowned for their ability to endure high heat without melting or deforming. This is due to aluminum's low melting point of 660°C (1220°F), which sets it apart from other metals. Consequently, aluminum coils are highly sought-after in industries such as automotive, aerospace, and HVAC, where heat resistance is paramount. In addition to excelling in extreme heat, aluminum coils also exhibit exceptional performance in freezing temperatures. This is attributed to aluminum's exceptional thermal conductivity, enabling it to efficiently transfer heat. As a result, even in frigid conditions, aluminum coils can promptly warm up and maintain a consistent temperature. Furthermore, aluminum's resistance to corrosion renders it an ideal choice for outdoor applications exposed to harsh weather conditions. Unlike other materials, aluminum does not rust or deteriorate when exposed to extreme temperatures, ensuring its durability and reliability. In conclusion, aluminum coils are specifically designed to withstand extreme temperatures, making them the preferred option for industries that prioritize heat resistance and long-lasting performance.

Send your message to us

Wide Aluminum Coil for Radiator - Grade Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords