Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

1. Detailed Specifications:

| Product | Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

3. Image:

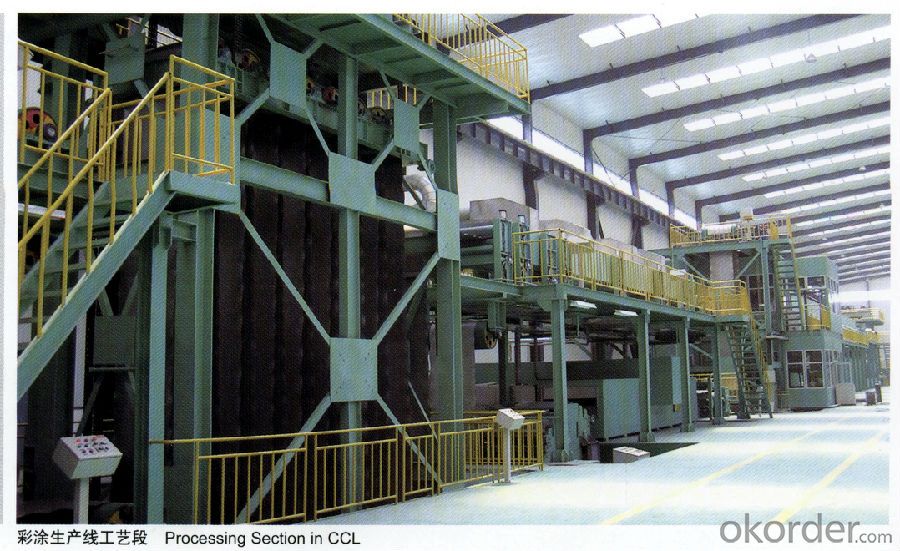

production Line:

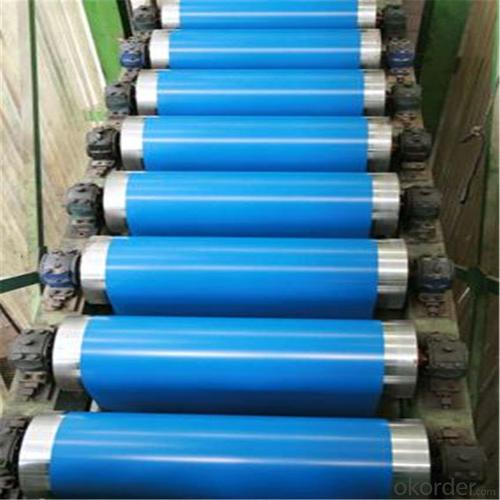

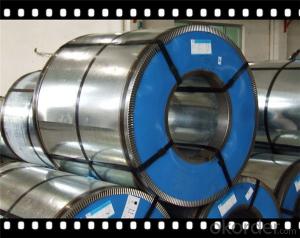

production show:

4.Packaging & Delivery

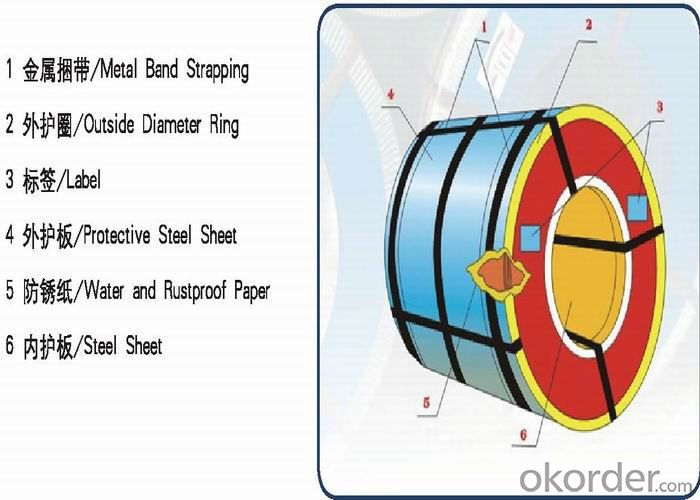

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q: What are the different types of steel coil storage racks?

- There are several different types of steel coil storage racks, including coil cradles, coil saddles, coil blocks, and coil storage bins. Each type is designed to safely and efficiently store steel coils based on their size, weight, and specific requirements.

- Q: I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Get a Kershaw hunting knife. Kershaw uses only good quality knife steel and they have plenty of hunting knives under $100.

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. Generally, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This coating process involves applying a thin layer of holographic material onto the surface of the steel coils, creating a visually striking and distinctive holographic pattern.

- Q: What are the different types of steel coil edge condition options?

- There is a variety of steel coil edge condition options available, each offering distinct characteristics and advantages. The most common types are as follows: 1. Mill Edge: This is the basic and widely used type of steel coil edge condition. It occurs naturally during the hot rolling process and is characterized by a rough and uneven edge. Mill edge coils are typically suitable for applications where edge quality is not crucial, such as general fabrication. 2. Slit Edge: Slit edge coils are produced by cutting the edges of the steel coil using a slitting machine. This process results in a smoother and more uniform edge compared to mill edge coils. Slit edge coils are often preferred for applications that require a higher level of precision, such as in the automotive or electrical industries. 3. Trim Edge: Trim edge coils are similar to slit edge coils but undergo an additional trimming process to eliminate any defects or imperfections from the edges. This creates an even smoother and cleaner edge, making trim edge coils ideal for applications where appearance and aesthetic quality are important, such as in architectural or decorative purposes. 4. Deburred Edge: Deburred edge coils undergo a deburring process to remove any sharp or burr-like edges. This is done to ensure safety and prevent injuries during the handling or processing of the coils. Deburred edge coils are commonly used in industries where worker safety is a priority, such as in construction or manufacturing. 5. Rounded Edge: Rounded edge coils have their edges rounded off to eliminate any sharp corners or edges. This type of edge condition is often utilized in applications where the coils will come into contact with delicate materials or surfaces, as it helps prevent scratching or damage. It is important to consider the specific requirements of the application and the desired outcome when choosing a steel coil edge condition. Each type offers its own unique benefits, and factors such as precision, appearance, safety, and functionality should be taken into account when selecting the appropriate option.

- Q: I was wondering what material most common motorcycle gas tanks are made out of? is it steel? stainless steel? aluminum? what are the advantages and disadvantages or each?

- Aluminum Motorcycle Gas Tank

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through visual inspection, magnetic particle inspection, or ultrasonic testing. Visual inspection involves examining the surface for any visible defects such as scratches, dents, or corrosion. Magnetic particle inspection uses magnetic fields and iron particles to detect surface cracks or defects that may not be visible to the naked eye. Ultrasonic testing involves using high-frequency sound waves to detect internal and surface defects in the steel coils. These inspection methods help ensure the quality and integrity of the steel coils before they are further processed or delivered to customers.

- Q: How are steel coils used in the manufacturing of industrial valves?

- Steel coils are used in the manufacturing of industrial valves as they provide the necessary raw material for creating valve bodies, stems, and other components. The coils are shaped, cut, and formed into different valve parts, ensuring strength and durability. These steel components are then assembled, welded, and machined to create fully functional industrial valves used in various applications such as oil and gas, chemical processing, and water treatment industries.

- Q: The steel is orangish in colour and is mostly made of copper

- Steel is an alloy of iron and carbon and optionally one or more of numerous other materials. Copper is normally not used, except sometimes in small percentages. Steel is never yellow or orange in color. Reactivity of steel depends on the materials it is alloyed with. Chromium and nickel with steel make stainless steel, which is much less prone to reactive than iron. .

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- Steel plate is divided into many kinds of PU, low alloy, boiler plate, vessel plate, high strength plate, etc..

Send your message to us

Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords