White HDPE Tarpaulin with UV Treated Print Logo

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PE Tarpaulin with UV Treated Logo:

PE fabric both sides laminated, reinforced by PP rope in hem on all around edges. Aluminum eyelets every 1 meter or 3’ or 1yd interval (30cm, 50cm interval also available).

Specification of PE Tarpaulin with UV Treated Logo:

Weight: 70g/m2-300g/m2

Density / sq. inch :7*6, 7*7, 8*7, 8*8, 10*8, 10*10, 12*12, 14*14, 16*16

Color: Any color available

Size: 2*3m, 3*4m, 4*6m….. any size available

Denier: 750-3000 Denier

UV. FR treatment also available

PE fabric both sides laminated, reinforced by PP rope in hem on all around edges. Aluminum eyelets every 1 meter or 3’ or 1yd interval (30cm, 50cm interval also available).

Application of PE Tarpaulin with UV Treated Print Logo:

PE Tarpaulin can be widely used in as the cover as well as other usage. It can be used in industrial, agricultural, garden and home.

Industrial: Covers for general use, scaffoldings in construction sites, underground sheets,

Covers for truck, cars, boats, containers, warning tapes,

Covers for materials, roofs, road repair sites, fences

Agricultural: Covers for timber, hay, cotton and all kinds of crops

Covers for daring crops

Home/Garden use: Covers for garden, backyard use

Covers for furniture

Gazebo tentd, dining canopies, swimming pool covers

Packing of PE Tarpaulin with UV Treated Print Logo:

1. For rolls , packed in a plastic bag with a label between rolls and bag

2. For Tarpaulin sheets, Each piece in a polybag with a label then proper pieces in a carton box packing or same color bale packing

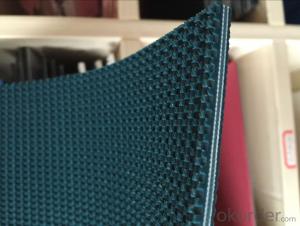

Picture of PE Tarpaulin UV Treated Print Logo

- Q: How do you glue a broken plastic basin?

- Find you a soft plastic, burn it, drop the drop of plastic in the dew place!!

- Q: What are the different materials used to make olive nets?

- The different materials used to make olive nets include polyethylene, polypropylene, and nylon.

- Q: What is the plastic bottle used to make after crushing?

- Plastic is a component of polymers, which has a thermal reshaping, that is, heating the plastic, turning it into a liquid, re plasticity, producing new plastic bottles, or other plastic products!

- Q: How does an olive net affect the harvesting efficiency?

- An olive net significantly improves harvesting efficiency by simplifying the process. The net is spread out beneath the olive tree, and when the tree is shaken or mechanically stimulated, the olives fall onto the net, making it easy to collect them. This eliminates the need for manual picking and reduces the time and effort required for harvesting, thus increasing efficiency.

- Q: How does an olive net help prevent damage to the olives during harvesting?

- An olive net helps prevent damage to the olives during harvesting by creating a protective barrier that catches the falling olives. This prevents them from hitting the ground and potentially getting bruised or damaged.

- Q: How do olive nets impact the overall cost of olive production?

- Olive nets can have a positive impact on the overall cost of olive production. By using nets, farmers can protect the olives from damage caused by birds, insects, or adverse weather conditions, leading to a higher yield and reduced losses. This results in increased profitability and a lower overall cost of production. Additionally, olive nets can also facilitate the collection of olives, making the harvesting process more efficient and reducing labor costs.

- Q: Do olive nets protect against olive tree frost damage?

- No, olive nets do not protect against olive tree frost damage. Olive nets are primarily used for harvesting olives and preventing birds from eating the fruit. To protect olive trees from frost damage, other measures like covering the trees with frost blankets or using heaters or fans for air circulation are more effective.

- Q: Can olive nets be used on trees with a dense foliage?

- Yes, olive nets can be used on trees with dense foliage. Olive nets are designed to catch falling olives during harvesting, regardless of the density of the tree's foliage.

- Q: Do olive nets affect the flavor of the olives?

- No, olive nets do not affect the flavor of the olives.

- Q: How do olive nets prevent fruit oxidation in olives?

- Olive nets prevent fruit oxidation in olives by providing a protective barrier that shields the fruits from direct exposure to sunlight and oxygen. These nets cover the olive trees, preventing the olives from getting overripe or sunburned, which can lead to oxidation and deterioration of the fruit. By reducing the contact of olives with air and sunlight, the nets help to maintain the quality and freshness of the olives, preventing them from undergoing the oxidation process.

Send your message to us

White HDPE Tarpaulin with UV Treated Print Logo

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 1000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords