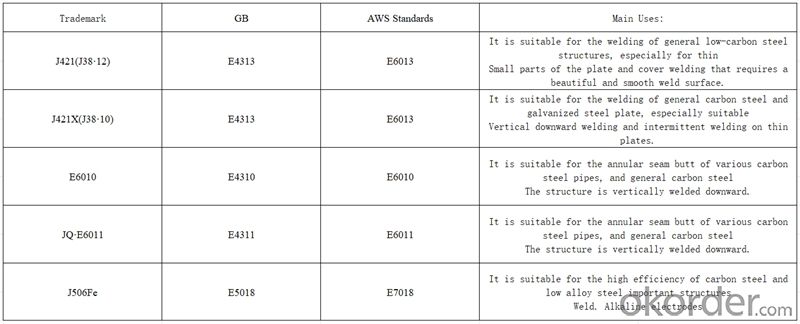

Welding Electrodes for Welding Steel pipes and Steel Plates E6013,E6010,E6011,E7018

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our welding electrodes products boasts a combination of durability, versatility, and ease of use that sets them apart in the industry.

It engineered to deliver exceptional performance, reliability, and versatility across a wide spectrum of welding applications. These electrodes are meticulously designed and rigorously tested to ensure they meet the highest industry standards, making them an ideal choice for professionals and enthusiasts alike.

High-Quality Core Material:

Our products crafted from premium-grade steel materials, our welding electrodes are designed to withstand high temperatures and maintain their strength during the welding process. This ensures a strong, reliable weld joint.

Versatile Applications:

Suitable for use in both AC and DC welding environments, our electrodes cater to a diverse range of welding tasks including mild steel, stainless steel, cast iron, and low-alloy steel welding. Enhancing your work's flexibility and efficiency.

Compliance & Safety:

All our welding electrodes comply with international safety standards and regulations, ensuring the safety of both welders and the environment during use.

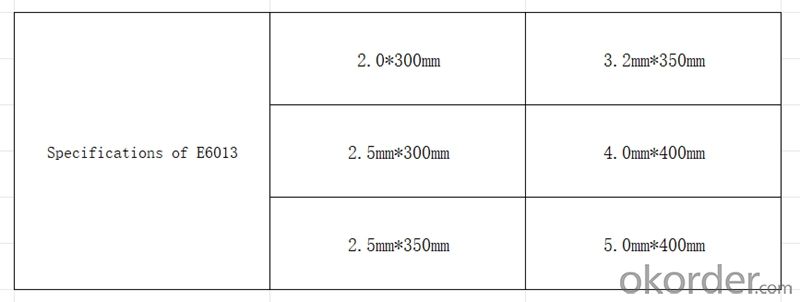

Our Regular Specifications:

1)WELDING ELECTORODES:

AWS:E6013,E6010,E6011,E7018

DIAMETER:2.0mm-5.0mm

LENGTH:300mm,350mm,400mm

2)WELDING WIRE--STANDARD

AWS:ER70S-6,E71T-1C,E71T8-Ni1-J

MIG WIRE AND FLUX CORED WELDING WIRE

MIG WIRE ‘S DIAMETER: 0.8mm、0.9mm、1.0mm、1.2mm

15kg/D270;5KG/D200

FLUX CORED WELDING WIRE’S DIAMETER:1.0mm 1.2mm 1.6mm

15kg/D270, 5KG/D200

3)WELDING FLUX:

1.SURFACING FLUX -CORED WELDING WIRE

2.CARBON STEEL AND LOW-ALLOY STEEL SUBMERGED ARC WELDING WIRE

3.SINTERED FLUX

- Q: 400A DC inverter welding machine, suitable for long welding electrode

- 3.2.................. But it depends on what you're welding

- Q: What type of welding machine does not use electrode welding machine?

- The welding machine without electrode is of the same type, that is, common standard welder.Because the welding machine interface size can be adjusted, you can use a variety of electrodes. Instead of an electrode with a welding machine.The electrode (covered electrode) is a strip of metal gas welding or welding when the filler metal in the joint welding of the workpiece. The electrode material is usually the same as the material of the workpiece.

- Q: Please tell me the current corresponding to various types of welding electrodes in detail!

- Empirical formula for welding current and electrode diameter: I=dk I--- welding current (A); d--- electrode diameter (mm); k--- empirical coefficient (30~50)Welding current of phi 2.5 electrode is 50A ~ 80AWelding current of phi 3.2 electrode is 100A ~ 130AWelding current of phi 4 electrode is 160A ~ 200AMore than 4 of the diameter welding current is 200A ~ 250A

- Q: What type of welding rod is used for welding 16MnD?

- J507, preheat 150 degrees before welding, choose different welding current and voltage according to different wire diameter.2.5, 3.24575-100, 110-130, 150-165, 230-250

- Q: What wire and electrode are used for the welding of 0Cr18Ni10Ti stainless steel pipes? Thank you

- 1, 0Cr18Ni10Ti stainless steel pipe welding using H0Cr20Ni10Ti welding wire, welding rod using A132 or A137.2, if welding with electrodes, I suggest the use of A137 welding, because of its crack resistance performance than A132 much better.

- Q: J422 electrodes are marked with "THJ422". What does TH represent?

- J422 is the brand of welding rod GB. As for the TH is the enterprise stipulated grades, the first letter T should be on behalf of the welding electrode (strip of the first letter); second letters H, should be related to the electrode trademark or manufacturer's name.

- Q: How long is the effective period of welding rod?

- If the stock period exceeds the prescribed time limit, the electrode, flux and flux cored wire must be re examined before the relevant functional departments can be issued and used. complexTest principle to check whether the welding material may affect the quality defects, generally limited to appearance and process performance test, but there are doubts on the performance of welding materials, can increase the necessary inspection item.The prescribed time limit may be determined by the following method from the date of production:A) the period of recommendation for welding materials, quality certificates or manuals;B) a low hydrogen type welding material for acid welding materials and moisture resistant packages, sealed for two years;C) graphite type welding materials and other welding materials for one year.

- Q: What is the price of titanium - calcium welding rod and low hydrogen type electrode?

- The calcium titanium electrode and the low hydrogen electrode are the type of electrode. The coating composition of titanium calcium type refers to the electrode with titanium dioxide and calcium carbonate, acidic and low carbon steel electrode, hydrogen electrode is the electrode with low hydrogen material such as low hydrogen sodium or potassium hydrogen based low carbon steel electrode is alkaline. The coating composition is different, so the welding process performance difference is relatively large, acidic carbon electrode process performance is stable, the basic AC / DC arc stability; alkaline and carbon steel electrode because of easily ionized material, arc stability is relatively poor, and many can only adapt to the DC welding welding, the weld metal the hydrogen content is low, so it can ensure the internal quality of weld. As for the price, can not be generalized, titanium calcium welding rod some prices higher than the low hydrogen electrode, but experience, low hydrogen electrode price than titanium calcium type electrode price is higher, about 500-700 yuan per ton. Because I manufacture welding materials.

- Q: I want to buy a small inverter welder, I heard that welding machine is very light, how heavy is it? It's the kind of carry. And how much is the price?. I wonder if the welder can use an acid welding rod? When welding, is it the same as the feeling of communication? I used the DC blow, it seems a little big. It's not good at all.. There is also a big point of 315 inverter welding machine, how much is it?.

- The kind of welding machine that you said could be used with an acid electrode. He has many functions, which can be shared by AC and DC, with separate DC or AC, of course, the price is different. About 20KG or so, the market is now available from 300-800. Import, brand, public can not be the same, the price varies greatly. The big 315 is now 450-550 between.

- Q: What kind of material is E4303 electrode?

- E4303 electrode, it's made of carbon steel

Send your message to us

Welding Electrodes for Welding Steel pipes and Steel Plates E6013,E6010,E6011,E7018

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches