Geotextile Drainage Fabric Warp Glass Fiber Composite Geotextiles for Real Estate from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

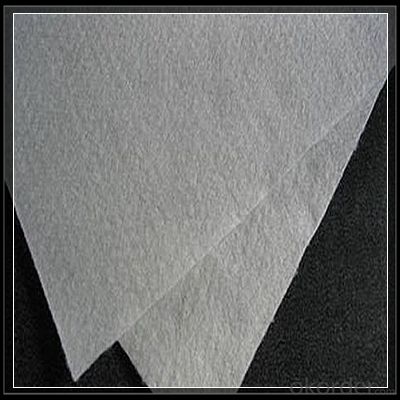

Warp knitted compound, that is bound by line by the warp, weft and acupuncture staple fiber geotextile layer repeatedly walk through, so that became one of the three series. Thus both the warp composite geotextiles with high tensile strength, low elongation characteristics, and both the performance of acupuncture nonwovens. Therefore, Warp is a composite geotextile reinforcement can be used for enhanced isolation protection, and has a three-dimensional integral method to gather and have good water levels, different role of water. Showed a solid matrix and pores because of its continuous phase, a porous filter effect, is a versatile geotextile composites. It is today a high level of application of the international geotechnical composite substrate.

Features:

High tensile strength, low elongation, vertical and horizontal deformation of the uniform, tear strength, excellent wear resistance, high permeability, filter and strong.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in railway track stabilization?

- Yes, geotextiles can be used in railway track stabilization. Geotextiles provide reinforcement and separation functions, preventing the mixing of materials and improving the stability of the track. They can help distribute loads, reduce deformation, and enhance the overall performance and lifespan of the railway track.

- Q: Can geotextiles be used in green infrastructure projects?

- Yes, geotextiles can be used in green infrastructure projects. They can serve as a key component in various applications such as erosion control, soil stabilization, and drainage systems. Geotextiles help to improve the overall performance and longevity of green infrastructure by providing reinforcement, filtration, and separation functions.

- Q: Can geotextiles be used for erosion control in golf courses?

- Yes, geotextiles can be used for erosion control in golf courses. Geotextiles are permeable fabrics that can be installed to stabilize soil and prevent erosion by providing a barrier against water flow. They are commonly used in various landscaping applications, including golf course construction and maintenance, to control erosion and improve soil stability.

- Q: Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q: Bentonite waterproof blanket and geotextile pond construction which is good

- Impermeable membrane construction convenience, waterproof blanket and high prices, the effect is better than impermeable membrane

- Q: What are the specifications for geotextiles and geogrids commonly used on expressways?

- You are the production, or sales, or procurement, the question asked, what model is the designer's decision

- Q: What are the installation techniques for geotextiles?

- There are several installation techniques for geotextiles, depending on the specific application and requirements. Some common techniques include trenching, anchoring, and overlaying. Trenching involves excavating a trench and placing the geotextile in the desired location, then backfilling the trench with soil or aggregate. Anchoring involves securing the geotextile to the ground using stakes or anchors, providing stability and preventing movement. Overlaying involves placing the geotextile on top of an existing surface, such as a road or landfill, to provide reinforcement and separation. The choice of installation technique depends on factors such as soil conditions, project specifications, and desired results.

- Q: What are the maintenance requirements for geotextile installations?

- The maintenance requirements for geotextile installations vary depending on the specific project and site conditions. However, in general, some common maintenance requirements for geotextile installations include regular inspection for damage or erosion, ensuring proper drainage and sediment control, removing any debris or vegetation that may accumulate on the geotextile, and addressing any issues or repairs promptly to prevent further damage. It is important to follow the manufacturer's guidelines and recommendations for maintenance to ensure the longevity and effectiveness of the geotextile installation.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavy materials like concrete or steel. Secondly, geotextiles have a high strength-to-weight ratio, providing excellent reinforcement and stabilization capabilities for soil and other materials. Additionally, geotextiles are permeable, allowing for proper drainage and preventing water buildup, which can lead to erosion or structural damage. Moreover, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring their long-term durability. Lastly, geotextiles are cost-effective, as they require less labor and equipment for installation and maintenance compared to traditional materials. Overall, the use of geotextiles offers numerous benefits in terms of efficiency, functionality, and sustainability in construction projects.

- Q: Geotextile use

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

Send your message to us

Geotextile Drainage Fabric Warp Glass Fiber Composite Geotextiles for Real Estate from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords