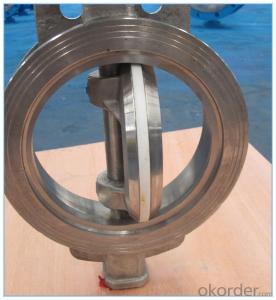

Wafer Type PTFE seated Butterfly Valve with Handle wheel/Lever operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wafer Type PTFE seat Butterfly Valve with Handle wheel/Lever operation

The Butterfly Valve Standard

Designed: API609, ASME B 16.34,AWWA C 504, BS EN593

Face to Face: API 609,AWWAC504, BS2080, and ISO5752

Flange End: ASME B 16.5, ASMEB 16.47, BS EN1092, ISO7005

Inspection Test: API 598, BSEN 12266, ISO 528

Materials Choose

Body Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Disc Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

SeatMaterials:304/316/Graphite/Asbetos/PTFE

Specifications

Pressure:PN10/PN16/PN25/CL150/CL300

Size: DN40---DN3200

Drive Mode: Manual/Wormgear/Electric/Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

Delivery:

within 15-30days after receipt of at sight L/C or 30% as advance payment by T/T

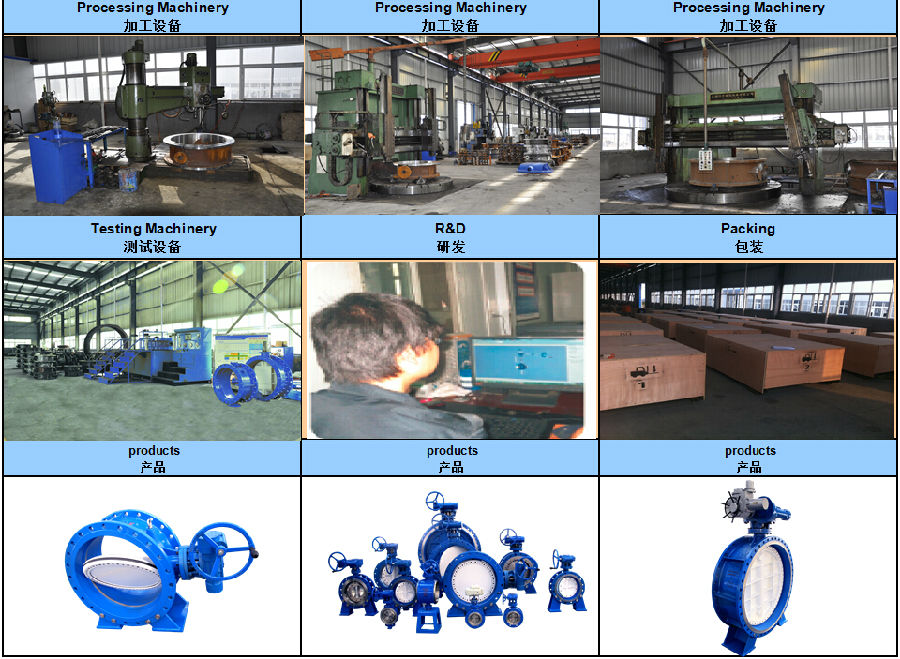

Butterfly Valve Packing: Seaworthy packing:

1. Single Butterfly Valve is packed with foam plastic bag.

2. Put sponge in each floor

3. Electric or pneumatic actors will Individual packaging it with wood box.

4. Export Wooden Packing

5. We can pack according to specific customer requests.

6. Customers’ logos are available on package.

7. Design and manufacturing the wood box to save the sea cost if needed .

What can we do for you?

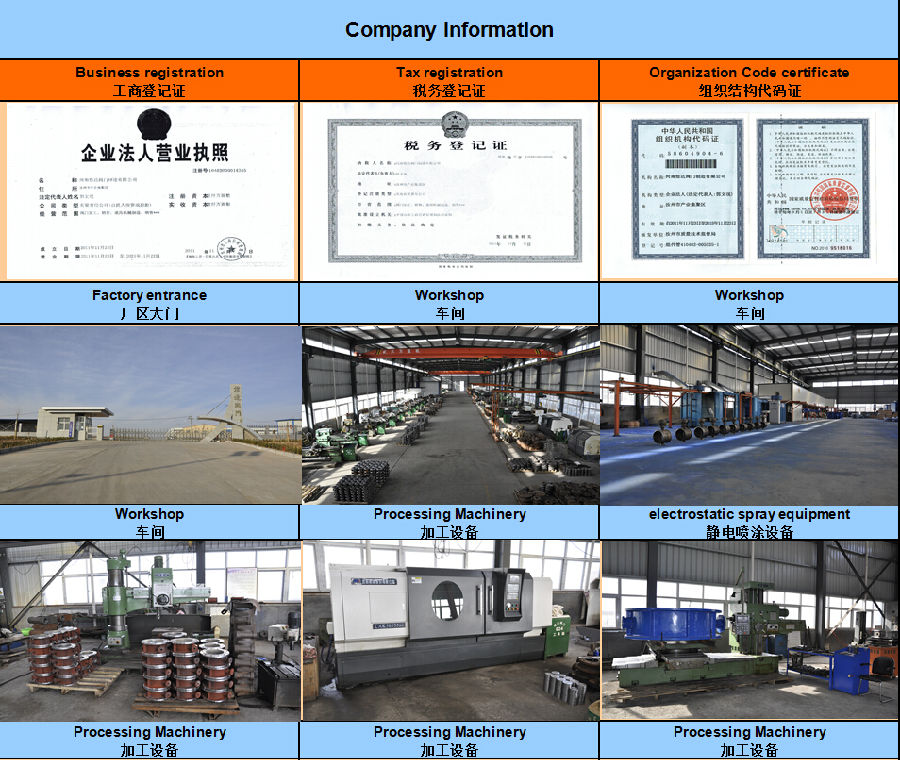

1. Save lots of your cost. As you know, more than 85% butterfly valves are made from Tianjin in China, our factory is located in this most advantage place too.

2. Your OEM orders are welcomed. We have own foundry, serve OEM customers from more than 23 countries.

3. Each valve is taken for two times pressure test before leave factory! Each butterfly valve has 24 months guarantee period.

4. You’ll never be low on supply---with our monthly capacity of 32000 sets.

5. More than 40 salesmen are always working with you and listening to you.

- Q: Classification of telescopic butterfly valve

- (2) temperature butterfly valve. 120 C<t<450 C butterfly valve(3) normal temperature butterfly valve. One 40C<t<; 120 C butterfly valve(4) low temperature butterfly valve. One 100<t< one, 40 C butterfly valves(E) ultra low temperature butterfly valve. T< one, 100 C butterfly valve (1) clip butterfly valve(2) flanged butterfly valve(3) lug butterfly valve;(4) welded butterfly valve

- Q: How do you draw the butterfly valve in the engineering drawing?

- Butterfly valve there are many kinds of painting, mainly designed to draw on the staff, according to the design institute out of the icon.

- Q: What is the medium flow rate when the centerline butterfly valve is fully open?

- After inspection, the product certificate shall be attached to the factory.Butterfly: also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control air, water, steam, all kinds of corrosive media, mud, oil, metals and radioactive liquid media and other types of fluid flow.

- Q: What are the advantages of butterfly valves?

- Butterfly valve, also known as shutter valve, its advantages are:A. has a large circulation capacity and is about 1.2 times the same size as two seat valves;

- Q: Butterfly valve general use occasions

- Valve is especially suitable for low differential pressure, large diameter, large flow of gas and slurry liquid. For general control valve, DN300mm is big valve, only individual to DN450, and for the butterfly valve, DN500 below is a small valve, DN500 ~ 1000 is the standard valve, the largest butterfly caliber up to 9m. Visible, large diameter pipe with the main butterfly valve.

- Q: What is the effect of nylon coating on butterfly valve plate? Thank you

- Mainly media will not be contaminated by rust on the body, you should say that the central soft sealing butterfly valve, the central valve is generally cast steel or cast iron material, so useNylon coatingLining up. There are soft seals, sealing performance is relatively high

- Q: What does butterfly valve do?

- [1] butterfly valve is also known as turn over plate valve, is a simple structure of the control valve, but also can be used for low pressure pipe medium switch control.[2] butterfly valve: butterfly valve refers to the closure of parts (valve or butterfly plate) for the disk, around the valve shaft to achieve rotation and closing of a valve, the main cut off on the pipe and throttling role. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve used in furnace, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection engineering system, conveying a variety of corrosive and non corrosive media pipeline, used to adjust and cut off the media flow. Butterfly valve categories are: handle butterfly valve, turbine butterfly valve, pneumatic butterfly valve, electric butterfly valve and so on.

- Q: Butterfly valve switch direction respectively?

- First, if the butterfly valve has been installed on the pipe, you can first see the mark on the handwheel. Second, there is a switch indicator on the general worm gear.

- Q: How can the flange butterfly valve be installed on the pipe?

- Outlet pipe configuration.If in the pipeline, the valve in order to do not bear the direction of the force and bending moment, it is best to set the valve at the exit side of the expansion joint. Valve opening and closing valve water pressure should not be borne by the foot, but through the valve flange, by the pipeline to bear as well.Butterfly valve structure is generally shorter length, and its butterfly plate will be extended to adjacent pipes or other parts, so be careful not to collide with other parts and interference. And to prevent the error matching pipe diameter greater than C and collide with the butterfly plate.Butterfly valve as a regulator, just adjust the flow and pressure. The valve is regulated by loss of pressure.

- Q: DN80 flange butterfly valve, DN80 flange butterfly valve DN80, flange butterfly valve DN80 what is the difference?

- Of course there are differences, the general market sales of the DN80 are many flange plate copper rod butterfly valve, quality can not reach the national standard, to use copper rod copper butterfly valve quality is king.

Send your message to us

Wafer Type PTFE seated Butterfly Valve with Handle wheel/Lever operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches