Wafer Type Eccentric Butterfly Valve DN300 PN16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wafer Type Butterfly Valve DN300 PN16

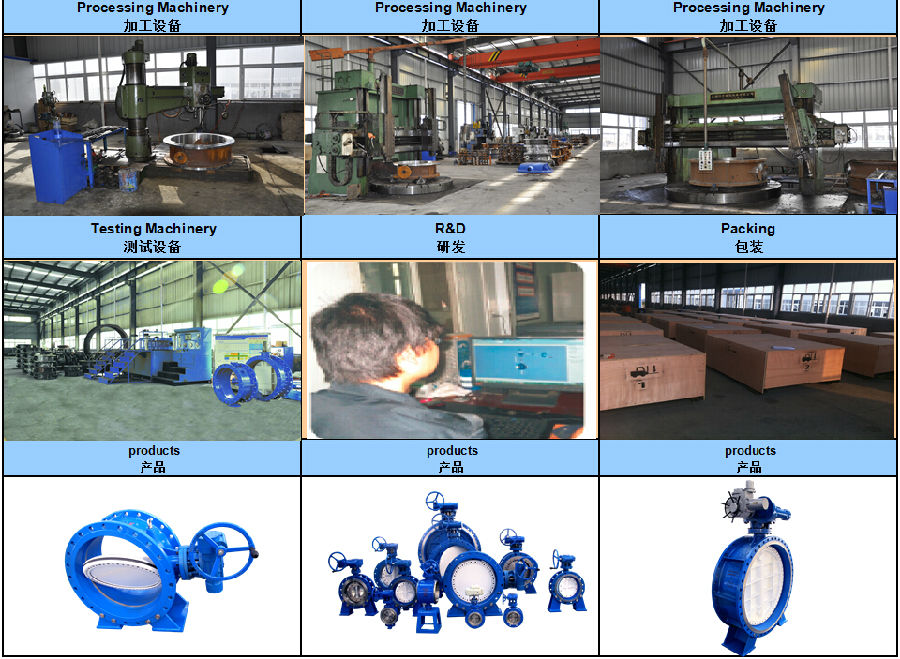

The Butterfly Valve Standard

Designed: API609, ASME B 16.34,AWWA C 504, BS EN593

Face to Face: API 609,AWWAC504, BS2080, and ISO5752

Flange End: ASME B 16.5, ASMEB 16.47, BS EN1092, ISO7005

Inspection Test: API 598, BSEN 12266, ISO 528

Materials Choose

Body Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

Disc Materials:WCB/WCC/LCB/QT450-10/QT500-7/CF8M/CF3M

SeatMaterials:304/316/Graphite/Asbetos/PTFE

Specifications

Pressure:PN10/PN16/PN25/CL150/CL300

Size: DN40---DN3200

Drive Mode: Manual/Wormgear/Electric/Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

- Q: Today saw the butterfly valve and butterfly valve, I do not know what is the difference between the two

- It should be the same. Butterfly valve (also called butterfly) English Name: butterfly valve: headstock disc disc disc plate and can rotate around the axis of the valve body of a valve rotating. Construction: mainly composed of valve body, valve stem, disc and sealing ring. The valve body is cylindrical and has short axial length and is internally provided with a plate.

- Q: Transformer butterfly valve and pressure relief valve difference

- The butterfly valve is usually fitted with an oil immersed transformer between the tank and the radiator to control the flow of oil between the transformer tank and the heat sink. When large power transformers are delivered, the radiators are usually individually packed to reduce transport sizes. The butterfly valve is closed to prevent the outside air or water from entering the transformer tank. When the transformer is transported to the installation site, the radiator is installed on the butterfly valve one by one. When the radiator is installed, the butterfly valve can be opened so that the oil flow between the transformer, the oil tank and the radiator can be circulated, so as to play the role of heat dissipation.When the transformer is running, it is found that when the radiator has seepage, the butterfly valve can be closed to avoid further leakage of transformer oil, and a new radiator can be replaced.

- Q: What does "10" in the butterfly valve "D71X-10" mean?

- The pressure of 10 kg 1.0MPA is usually cast iron

- Q: The difference between butterfly valve and gate valve

- Its varieties and quantities are still expanding, and the development of high temperature, high pressure, large caliber, high sealing, long life, excellent regulation, as well as multi-function development of one valve. Its reliability and other performance indicators have reached a high level. Disadvantages, there is a certain resistance to the medium. Gate valves are more used in steam pipes and large diameter water supply pipelines, because of the general requirements of fluid resistance is small, the use of gate valve. Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open. Need a higher installation space, the valve sealing surface has a certain self sealing capacity, its spool by the media pressure closely with the valve seat sealing surface contact, to achieve tight leakage.

- Q: How much is the Honeywell butterfly DN300?

- Find the agent or find a reliable valve plant a lot of foreign brands are in Chinese OEM so find a reliable factory is relatively good service to keep up

- Q: Have an iron block, aluminum heads, solid roller lifters, Jessel rocker shafts, what should my valve clearances be cold, and hot??

- Because you apparently have a built engine here rather than a factory assembly which simply has solid lifters, and the data you have is either inconclusive or conflicting then I will recommend the following procedure: Assemble them cold and adjust to Intake .010 and exhaust .020. After firing up the engine, adjust the carb, if it is so equipped, to a smooth rich idle and run it in for a couple of hours mixing idling with moderate load and a few full throttle pulls through 2nd gear to seat the rings. Bring it back into the shop good and hot and set the valve clearances at .008 intake and .016 exhaust hot. After adjusting the valves readjust the idle to 700 RPM and set the timing. initially set the timing at about 2 degrees BTDC until you hav run in the engine, If you are without clear specifications for timing use a vacuum gauge and play with it between 2 and 10 degrees BTDC with the vacuum advance disconnected and plugged, you are looking for the highest vacuum at idle as a starting point. Run it hard including lugging it in high gear at around 2500 to 3500 rpm at or near full throttle, if you are getting spark knock back it down 2 degrees at a time until it does not knock when lugged. If you get no spark knock when lugging it you might try advancing the timing 2 degrees above the vacuum indicated optimal setting but do not go beyond that point. After setting the valves and timing readjust the carburetor to the best lean idle and set to 650 to 700 rpm depending on where it feels comfortable. In the old days a lot of this was done totally by ear - hence the term engineers. Today I think most holders of that revered title do not have a clue where the term came from.

- Q: What does the triplex of pneumatic butterfly valve mean?

- Air pressure reducing valve, filter, oil mist these three parts

- Q: Specifically an engine valve retainer.

- There okorder for year make model engine valve diagram and you should find a drawing of your setup.

- Q: e.g. a patient with a prosthetic aortic valve and a patient with a prosthetic mitral valve. Also, can you get stenosis of mechanical valves or just tissue grafts?Thanks!

- mechanical okorder /

- Q: Hey YA! I am looking at getting an 01 Honda Prelude this month and valve adjustment keeps coming up when people discuss this car and other cars as well. What is this? Does it cost a lot to do, and is it important? Thank you!

- Adjusting hydraulic lifters, also called setting the valve lash provides the necessary travel and operation for the opening and closing of the intake and exhaust valves. Most new vehicles use hydraulic lifters, since their operation and design provides an easy and simple method of keeping the valve train in synchronization. You can perform the adjustment with a cold, static engine or during engine idle once the operating temperature has been reached. Adjusting the lifters on a running engine, however, can present a problem with oil splashing upward from the tappets. They make a spring clip to prevent it from getting all over the engine and compartment. Cost vary from city to city Mechanic to mechanic Hope it helps Lr

Send your message to us

Wafer Type Eccentric Butterfly Valve DN300 PN16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches