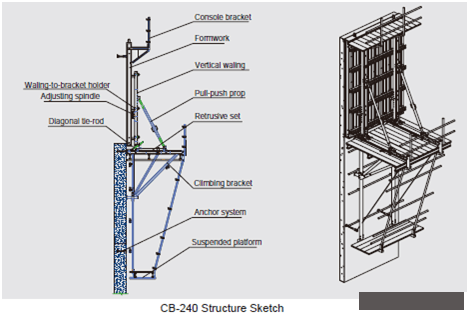

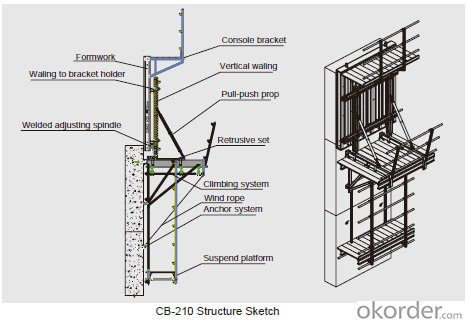

Vertical Structure Support System for Climbing Bracket CB240 & CB210

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

2. Main Features of Climbing Bracket CB240 & CB210

-High bearing capacity

-Simple moving procedure by crane

-Fast striking process without a crane

-Safe with work platform

3. Climbing Bracket CB240 & CB210 images

4. Climbing Bracket CB240 & CB210 Specifications

5. FAQ of Climbing Bracket CB240 & CB210

1) What can we do for you?

.We can ensure the quality of Climbing Bracket CB240 & CB210 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: How is the load capacity of a steel prop determined?

- The load capacity of a steel prop is determined by various factors such as the material's physical properties, dimensions, and design specifications. It is typically determined through rigorous testing and analysis conducted by engineers, considering factors like the prop's diameter, wall thickness, height, and the type of material used. These tests assess the prop's ability to withstand vertical loads, lateral forces, and other dynamic loads, ensuring that it can safely support the intended weight and maintain structural stability.

- Q: What are the main considerations when using steel props for supporting false ceilings?

- When utilizing steel props to support false ceilings, there are several key factors to take into account. To begin with, it is vital to ensure that the steel props are sized and strengthened appropriately to bear the weight of the false ceiling. The weight of the false ceiling will vary depending on factors such as the materials utilized and the size of the area it covers. It is crucial to select steel props with a load-bearing capacity that surpasses the weight of the false ceiling in order to guarantee stability and safety. Next, the height and spacing of the steel props must be carefully calculated and planned. The spacing between the steel props will depend on the size and weight of the false ceiling, as well as any additional loads that may be placed on it, such as lighting fixtures or ventilation systems. It is important to ensure that the spacing of the steel props is sufficient to evenly distribute the weight of the false ceiling and any additional loads. Another consideration is the installation process of the steel props. It is vital to adhere to the manufacturer's instructions and guidelines for proper installation. The steel props should be securely anchored to both the floor and the ceiling to prevent any movement or instability. Additionally, regular inspections of the steel props should be conducted to ensure they remain in good condition and are not damaged or weakened over time. Furthermore, fire safety is a crucial consideration when using steel props to support false ceilings. While steel is a fire-resistant material, it is important to ensure that the false ceiling materials and any insulation used are also fire-resistant. Adequate fire protection measures should be in place to prevent the spread of fire in case of an emergency. Lastly, it is important to take into account any building regulations or codes that may pertain to the installation of steel props for false ceilings. Local building codes may have specific requirements regarding the use of steel props, such as minimum load-bearing capacities or installation methods. It is essential to comply with these regulations to ensure that the installation is safe and meets the necessary standards. Overall, the main considerations when utilizing steel props for supporting false ceilings include selecting appropriate prop size and strength, calculating height and spacing, proper installation, fire safety measures, and compliance with building regulations. By carefully considering these factors, one can ensure the safe and effective use of steel props for supporting false ceilings.

- Q: Can steel props be used in residential construction projects?

- Yes, steel props can be used in residential construction projects. Steel props, also known as adjustable steel props or steel shores, are temporary supports used to provide vertical support to structures during construction or renovation. They are commonly used in residential construction projects to support beams, walls, and other load-bearing elements. Steel props are preferred in construction due to their strength and adjustability. They can be easily adjusted to the required height and provide stable support to heavy loads. They are typically made of high-quality steel, which ensures their durability and ability to withstand heavy loads. In residential construction projects, steel props can be used in various scenarios. For example, they can be used to support temporary beams during the installation of new windows or doors, to provide additional support to walls during demolition or renovation, or to support the weight of a temporary roof structure during the construction of a new floor. Furthermore, steel props are versatile and can be easily adjusted to fit different heights and angles, making them suitable for various applications in residential construction. They can be quickly installed and removed, saving time and effort in construction projects. However, it is important to note that the use of steel props should be done by professionals who have the necessary knowledge and experience to ensure their safe and proper installation. Improper use of steel props can lead to accidents or structural failures, which can be dangerous and costly. In summary, steel props can be effectively used in residential construction projects to provide temporary support to structures. Their strength, adjustability, and versatility make them a reliable choice for supporting various load-bearing elements. However, it is crucial to ensure that they are installed correctly by qualified professionals to ensure safety and avoid any potential risks.

- Q: How do steel props compare to jack posts in terms of performance?

- Temporary supports in construction and renovation projects often include steel props and jack posts. While their purpose is the same, providing temporary structural support, they have performance differences. Steel props, also known as steel shore posts or acrow props, are adjustable steel tubes with a threaded end capable of extension or retraction to the desired height. Typically made from high-quality steel, they are designed to withstand heavy loads. Known for their strength, stability, and versatility, steel props are useful in various applications such as supporting walls, beams, and floors during construction or renovation. They are easy to install, require minimal maintenance, and can be adjusted to fit different heights and angles. Steel props are particularly preferred when dealing with larger and more complex structures due to their high load-bearing capacity. On the other hand, jack posts, also known as screw jacks or adjustable basement support poles, are more commonly used in residential applications, especially for temporary support in basements or crawl spaces. Comprising a steel post with a threaded rod, they can be adjusted by turning a nut at the top. Jack posts are generally lighter and less durable than steel props. They are designed for supporting lighter loads and are not suitable for heavy-duty applications. However, jack posts are more affordable and easier to transport and install compared to steel props. Regarding performance, steel props surpass jack posts in terms of load-bearing capacity and strength. They are capable of supporting heavy loads, making them more suitable for larger and more complex structures. Steel props offer greater stability and can be adjusted to fit various heights and angles, making them more versatile in different construction scenarios. Conversely, jack posts are more suitable for lighter loads and residential applications, where their affordability and ease of installation are advantageous. In conclusion, steel props and jack posts both serve as temporary supports but differ in performance. Steel props are stronger, more stable, and versatile, making them suitable for heavy-duty and complex construction projects. Jack posts, however, are more affordable and easier to install, making them preferable for lighter loads and residential applications. The choice between the two depends on the specific project requirements and load-bearing needs.

- Q: How do you determine the correct size of a steel prop for a specific application?

- Determining the correct size of a steel prop for a specific application involves several factors that need to be considered. Firstly, it is essential to assess the load-bearing capacity required for the specific application. This involves calculating the weight and force that the steel prop will be subjected to during use. Factors such as the weight of the materials being supported, the span or distance between the props, and any additional loads or forces that will be applied should be taken into account. Additionally, the height or vertical distance that needs to be supported is crucial in determining the correct size of a steel prop. Longer props may be required for higher heights to ensure adequate stability and support. The type of steel used in the prop is another important consideration. Different grades of steel have varying load-bearing capacities and durability. It is important to consult with industry standards and guidelines to determine the appropriate grade of steel for the specific application. Furthermore, local building codes and regulations need to be considered when determining the correct size of a steel prop. These regulations may dictate specific requirements or limitations on the use of props, such as maximum weight capacities or minimum safety factors. Compliance with these regulations is essential to ensure the safety and structural integrity of the application. In summary, determining the correct size of a steel prop for a specific application requires considering the load-bearing capacity required, the height to be supported, the grade of steel used, and compliance with local building codes and regulations. Consulting with industry standards and guidelines, as well as seeking professional advice if necessary, can help ensure the correct size is determined for a safe and successful application.

- Q: Are steel props suitable for use in the construction of bridges?

- Yes, steel props are suitable for use in the construction of bridges. Steel props, also known as shoring systems or temporary supports, are commonly used in bridge construction to provide temporary support to the structure during construction or repair work. Steel props offer several advantages that make them suitable for bridge construction. Firstly, steel is a strong and durable material, capable of withstanding heavy loads and adverse weather conditions. This makes it an ideal choice for providing temporary support to bridge components such as beams, girders, or decks. Additionally, steel props are adjustable, allowing for easy installation and customization based on the specific requirements of the bridge construction project. They can be extended or retracted to provide the necessary support height and can be easily secured in place using various locking mechanisms. This adjustability ensures that the temporary support system can accommodate the changing needs of the construction process. Moreover, steel props are lightweight and easy to transport, making them convenient for use in bridge construction projects. Their modular design allows for quick assembly and disassembly, saving time and labor costs. Furthermore, steel props are versatile and can be used in various bridge construction scenarios, including the construction of new bridges, bridge repairs, or bridge widening projects. They can be used in combination with other temporary support systems, such as formwork or scaffolding, to ensure the stability and safety of the bridge during construction. In conclusion, steel props are suitable for use in the construction of bridges due to their strength, durability, adjustability, versatility, and ease of use. They provide temporary support to bridge components, ensuring the stability and safety of the structure during construction or repair work.

- Q: Are steel props adjustable in tight spaces?

- Yes, steel props are adjustable in tight spaces. Their telescopic design allows for easy adjustment and adaptability to fit various heights and spaces, making them a suitable choice for cramped or confined areas.

- Q: Can steel props be customized based on specific project requirements?

- Yes, steel props can indeed be customized based on specific project requirements. Steel props are versatile and can be adjusted in terms of height, size, and load capacity to suit the unique needs of different construction projects. This customization ensures that the steel props provide optimal support and stability for the specific project at hand.

- Q: Can steel props be used for supporting temporary screen walls and partitions?

- Yes, steel props can be used for supporting temporary screen walls and partitions. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary structures to provide support and stability. They are designed to be adjustable in height, making them suitable for different applications and varying load requirements. When it comes to supporting temporary screen walls and partitions, steel props can be an ideal choice due to their strength and stability. They can be easily installed and adjusted to the desired height, providing a secure and reliable support system for the screens and partitions. Furthermore, steel props are typically made from high-quality steel, which gives them excellent load-bearing capacity. This means that they can handle the weight of the screens and partitions without any risk of collapsing or sagging. The adjustable feature of steel props also allows for fine-tuning the height, ensuring a perfect fit and optimal support for the temporary walls and partitions. In summary, steel props are a suitable choice for supporting temporary screen walls and partitions. Their strength, stability, and adjustability make them an effective support system that can provide the necessary stability and security for such structures.

- Q: Can steel props be used for temporary support during bridge construction?

- Yes, steel props can be used for temporary support during bridge construction. Steel props are commonly used in construction projects to provide temporary support and stability. They are strong, durable, and adjustable, making them suitable for various construction applications, including supporting bridge structures during construction.

Send your message to us

Vertical Structure Support System for Climbing Bracket CB240 & CB210

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches