Thickest Ventilation Fire Resistant Aluminum Foil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Ventilation Fire Resistant Aluminum Foil Description:

Ventilation Fire Resistant Aluminum Foil is Alumium double layer flexible ducts are specifically produced for low and medium pressure hearting, cooling, ventilation, exhaust and air conditioning systems Air tight alum flexible ducts are produced from multi layers alum strengthened with high tension hard steel spring wire, it has high elasticity and flexibility

2.Main Features of the Ventilation Fire Resistant Aluminum Foil:

HealthyPE insulation material

Minimum echoes possible

Fire resistances, self-supporting, leaking proof & corrosion resistant

Completely flexible ducting for routine exhausting

Reinforced double-layer aluminum foil construction

Ideal for HVAC, bath and general ventilating application

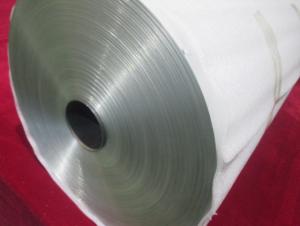

3. Ventilation Fire Resistant Aluminum Foil Images

4. Ventilation Fire Resistant Aluminum Foil Specification:

| diameter | spring wire (mm) | carton size(mm) | |

| space | diameter | ||

| 4" | 25 | 1.0 | 115*115*430 |

| 5" | 25 | 1.0 | 140*140*430 |

| 6" | 30 | 1.0 | 165*165*380 |

| 7" | 30 | 1.1 | 185*185*380 |

| 8" | 35 | 1.1 | 215*215*380 |

| 10" | 40 | 1.2 | 265*265*380 |

| 12" | 40 | 1.2 | 315*315*380 |

| 14" | 40 | 1.2 | 365*365*400 |

| 16" | 40 | 1.3 | 415*415*400 |

| 18" | 40 | 1.3 | 465*465*400 |

| 20" | 40 | 1.3 | 515*515*400 |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: If I use a aluminum foil baking pan and put 25 egg cardboard type of carton on the top and and use Poly Twine to soak up water up to the egg carton to water the seedsI can make this for a couple of dollars vs spending $100s for a professional seed growerMy only question is will the Poly Twine soak up water or what should I us to soak the water up?

- I have a few pots that have a false bottom plate that stand inside the pot but an inch above the pot bottomIts on legsThere is a hole in the side below this bottom plate to pour in waterThe plate has a wide cotton like strap that dips down below the plate on both end and the middle sits above the plateBy pouring water in the hole , this strap pulls it up to the soilBut egg carton may loose the water too fast by evoporationBesides, just one big square pan can give roots more space than those tiny cellsI would take that aluminum pan, poke holes in the bottom, fill with soil, plant seeds and periodically dip the whole pan in an inch of water for 15 minutes.

- Q: Just want an opinion.

- Take a small metal rod a coat hanger perhaps andscrape out the resin from the stem and bowlYou can then roll it into a ball.lol

- Q: It leaves this gross green satin on my fingerI wear it almost 24/7, its an antique.is that why? Help me!Thanks in advance.

- just use a turkey paster there basically the same thing and its long enough to get it all the way up there

- Q: WHAT DO YOU DO IF YOU SWALLOW,BY ACCIDENT,THE SMALL TAB ON THE TOP OF A PEPSIE CANDO YOU WAIT IT OUT AND LET THINGS PASS NATURALLY.IS IT DANGEROUSIAM AN ADULT.? HELP- NO DOCTOR YET SASHA

- A 45 pound felt paper is good for the first layerThe Second layer is the roof covering and can be one of several types1Half lap asphalt roll roofing is used with a 1/2 over lap and a layer of roof tar/cement that is applied between the overlap layersGalvanized or aluminum nails are applied to the surface that is overlapped at 12 spacing along this overlap area2A Bituminous roll roofing is applied with a large blow torch and propane fuelIt is pre cut to an over size and heated on the back side to soften the material as it is rolled out with a 4 overlapNo nails are needed since it is secured to the 45 pound felt, nailed Vigorously to the wood sheeting3Rubber/vinyl roofing is applied with an adhesive to the felt and secured around the edges with a metal strip that is them covered with a rubber stripA special cleaner and adhesive is required from the roofing supplier.

- Q: Find the volume of an aluminum can that has a radius of 6.5 centimeters and a heights of 18 centimeters use 3.14 and round to the nearest tenth.

- Few things are really bad for you in moderation and some are even goodSo don't forget to live! I see people trying so hard to live long lives that they forget that life is to be livedA saying I like goes something like this: You shouldn't sedately end life in a pristine, well perserved bodyRather, you should come sliding sideways into the end of life in a fully worn and used up body with a big grin exuberantly proclaiming Man! What a ride!

- Q: Hi- I've been learning a little bit about casting aluminum objects from a home foundry- I've come across the topic of shrinkage and this raises concerns:Suppose I want an aluminum copy of an object that is an exact match in size and shape.Say, the your intake manifold in your carWhat method of casting do I use? Close to the same size is nice but a 2% size difference would likely cause functional problemsLost foam? Pressing one half of the object into one half of a flask, then the other half of the object into the other?

- Well, in the strictest terms the bonding between carbon fiber (CF) and aluminum (AL) had better be at least a bit reactive or else you won't get a good bondThere are many AL parts that have a CF overlay but there are some things that you'll need to do for good success: 1) The AL must be phosphatized to exacuate the oxygen from the metalIt should be laminated immediately afterwards without touching the metal with your bare hands to avoid contamination; 2) The CF must be cured onto the AL using some kind of vacuum system, perhaps a strong plastic sealable bag into which the AL/CF item is placed, then the air pumped out using a vacuum pump; 3) You'll need to use thermoset epoxy that activates with peroxide to bond the CF to itself and the two objects togetherIt will be a rather high ratio, perhaps 20% to 25% epoxy to CF- makes for a messy day I know the answer because I design bike frames and parts utilizing this method.

- Q: i am fundraising for an exchange to frace next year and i have decided to sell caramel apples, but i dont know what to wrap them in without it getting stuck to the caramelany ideas?thanks (:

- Arabic there are quite a few letters in arabic which are meaningful even when used aloneEg: wa - and ka - like fa - so, thus, therefore hu - ( pronounced as who ) his ha - her ka - your e - my na - our lots more !!!.:-)) Urdu is another such language Eg : haan - yes to - so Hey dosen't english have such words too? Eg : so, NO( that definitely a complete sentence !!), bee, tea, sea, Good question.:-}

- Q: ok so we have to build a solar receptor kind of thing that will get warm and stay warm in the sun(learining about solar power) it can be made of anything but glass or metal (aluminum foil alowed) I'd like it to be made of mostly stuff i can find around the house or easy to find at storesand it can't be too big( able to fit in a larger locker.)ANY IDEAS??

- You might be talking of silver-leaf; which is simply flattened silver that adheres to almost anything you press it onGold-leaf is much better known and acts the same way.

- Q: Alpha raysBeta raysGamma raysProton raysI think it's beta rays, am i right?

- Yes bet rays can penetrate paper and your skin but is stopped by aluminium or woodGamma is only stopped by a couple of metres of leadAnd alpha is stopped by paper or your skinSo yes beta.

- Q: Aluminum and iron (III) oxide, Fe2O3, react to form aluminum oxide, Al2O3, and ironFor each mole of aluminum used, 426.9 kJ of energy is released under standard conditionsWrite the thermochemical equation that shows the consumption of 4 mol of Al(All of the substances are solids)Please help me how the chemical equation is sopposed to look like as wellIm sooo stucked! Please help!

- fiberglass is cheaper and a better insualtor that foam sheets but if you are having moisture problems you should defiantly stick with the foam

Send your message to us

Thickest Ventilation Fire Resistant Aluminum Foil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords