Vacuum Bagging Film-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vacuum Bagging Film

Product Description

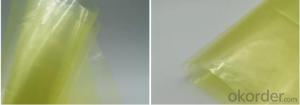

Vacuum bagging film is widely used in the composites industry, in vacuum infusion process, vacuum bagging pressure process and autoclave process. It is a technique in which you create uniform pressure to the surfaces of the obiect inside of a bag, holding parts together while the adhesive cures. Pressurizing a composite lamination serves several functions. It removes any trapped air between layers and provides pressure that prevents shifting of fiber orientation during cure. It also reduces humidity and improves the fiber-to-resin ratio in the composite part.

Technique Data

Temperature:150℃

Thickness:65μm,50μm,75μm

Width:≤14m

Length:Tailored

Density:1

Colour:yellow

Longitudinal Tensile Strength:>35MPA

Tensile Strength crosswise:>40MPA

Longitudinal elongation:>300%

Elongation crosswise:>350%

- Q: 3.2*2.5 meters cloakroom, in the corner of the section how to deal with? How about making a corner with each other?

- Wardrobe length can not just try the wall size, and then need to find a special treatment of corner products, in order to use the corner of space, some commodities also take into account consumer spending habits, but also made such products,

- Q: How can the aluminum alloy window be fixed with the corner and the whole frame?

- The general approach is to fix the whole frame in the frame mounted on the wall and hit the iron, steel nails or expansion screws, then iron and fixed, then fill foam, after solidification with cement lime and smooth wall.

- Q: How should the TV wall be installed on the corner?

- Chinese traditional style TV wallIf you prefer China's long established traditional cultural atmosphere, then hang a group of calligraphy and painting on TV wall is also very elegant. The choice of calligraphy and painting is of great importance, "the small tree, the new painting is not ancient, the big must be the house."". Although only a simple set of calligraphy and painting, the living room has become the punchline, more fully reflects the owner's identity, status, talent, grade etc..

- Q: What is the position of the steering wheel sensor and what is its function?

- In addition, through the photoelectric encoder to collect corners, but in automotive applications, due to the reliability of photoelectric sensors and other issues, the use of less products, not much described here.

- Q: IKEA corner wardrobe 96cm size, why 73cm?

- Tolerance is accurate, and if you have a strong practical ability, the installation is smooth.

- Q: Shops corner how to decorate?

- Just make a publicity campaign based on your product

- Q: Ask about the product performance and advantages of DJ series corner band sawing machines!

- If you are interested, you can check the relevant product information at the super CNC website, and hope that my answer will help you.

- Q: Microcrystalline stone xinzhongyuan ceramics why stick after a period of time where the angle is easy to crack?

- Because they belong to the originator of Microcrystalline stone, we have been working with bode for many years, and there has been no after-sale problem. The design and quality of the bricks are excellent! Do not buy cheap Microcrystalline stone, cheap Microcrystalline stone will be easy to scrape, and the real Microcrystalline stone is very wear-resistant, and I hope to help you!

- Q: Plastic products surface of weld line, how to deal with the clip

- The weld line is also called the weld line and clip watermark, is due to the early part of the molten resin from different directions by cooling, at the combination failed to completely fusion came faintly. Can only be weakened or moved to irrelevant places.

- Q: Pcliao injection of smooth surface not light is going on

- This defect is commonly believed to occur frequently during die filling and pressure holding. In fact, dark spots appear near the gate and usually occur at the beginning of the injection cycle. Tests show that the occurrence of surface slip is actually due to the injection speed, or rather the flow velocity at the tip of the melt flow.

Send your message to us

Vacuum Bagging Film-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches