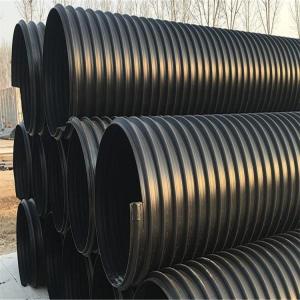

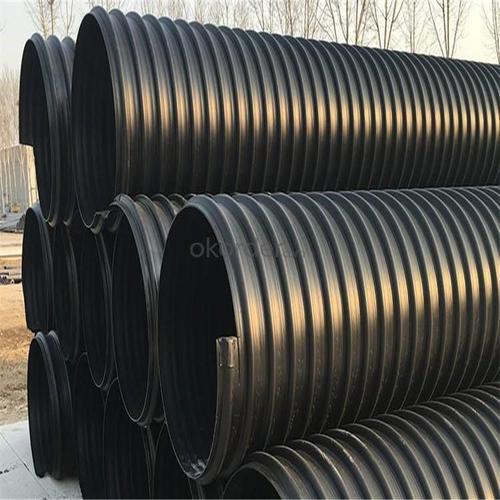

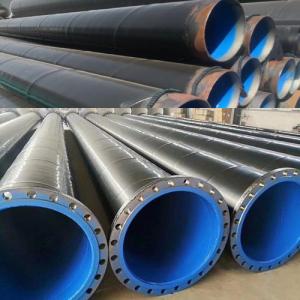

Underground Metal Reinforced PE Spiral Corrugated Pipe for Drainage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Metal Reinforced PE Spiral Corrugated Pipe for Drainage

Press grade: SN8/SN10/SN12.5/SN16

Size: DN300MM-DN1800MM

Standards:

Features:

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports used for aboveground steel pipes, including pipe hangers, pipe shoes, pipe clamps, and pipe rollers. These supports are designed to provide stability, prevent sagging, and distribute the weight of the pipe evenly, ensuring the structural integrity of the system.

- Q: Are steel pipes suitable for underground mining operations?

- Yes, steel pipes are suitable for underground mining operations. Steel pipes are known for their durability, strength, and resistance to corrosion, making them ideal for use in harsh underground mining environments. They can withstand high pressure and are capable of transporting various substances, such as water, air, or mining materials, with reliability and efficiency. Additionally, steel pipes can be customized to meet specific mining requirements, ensuring their suitability for underground operations.

- Q: How do you calculate the flow rate in a steel pipe?

- When calculating the flow rate in a steel pipe, several factors must be taken into consideration. The primary factor to consider is the cross-sectional area of the pipe, which can be determined using the formula A = πr², where A represents the cross-sectional area and r represents the radius of the pipe. Afterwards, it is necessary to ascertain the velocity of the fluid moving through the pipe. This can be accomplished by utilizing the equation v = Q/A, where v denotes the velocity, Q represents the volumetric flow rate, and A represents the cross-sectional area of the pipe. To determine the volumetric flow rate, one can employ the equation Q = AV, where Q represents the volumetric flow rate, A represents the cross-sectional area, and V represents the average velocity of the fluid. Furthermore, it is essential to take into account the properties of the fluid being transported through the pipe. Factors such as density and viscosity can impact the flow rate. In conclusion, the flow rate in a steel pipe can be calculated by determining the cross-sectional area of the pipe, calculating the velocity of the fluid, and considering the properties of the fluid being transported.

- Q: Are steel pipes more expensive than other types of pipes?

- The cost of steel pipes can vary compared to other pipe types due to various factors. In terms of upfront cost, steel pipes are generally more expensive than certain pipe types. This is primarily because the production process and raw materials for steel pipes are highly costly. Additionally, steel pipes are renowned for their strength and durability, making them a popular option for applications involving high pressure or extreme conditions. However, when considering long-term costs and benefits, steel pipes are often more economically viable. They have a longer lifespan compared to certain pipes, reducing the need for frequent repairs or replacements. Furthermore, steel pipes possess excellent corrosion resistance, making them suitable for diverse environments and reducing maintenance expenses over time. Moreover, the strength and durability of steel pipes contribute to a reduced likelihood of leaks or failures, resulting in significant cost savings to prevent damage or loss. When comparing the cost of steel pipes to other pipe types, it is crucial to consider the specific requirements and characteristics of the project or application. Factors like the transported fluid or material, required pressure rating, expected lifespan, and environmental conditions should all be taken into account. Ultimately, despite steel pipes having a higher upfront cost, their long-term durability and reliability often make them a cost-effective choice in numerous applications.

- Q: Are steel pipes resistant to impact?

- Yes, steel pipes are generally resistant to impact due to their high strength and durability. They can withstand external forces and are less likely to deform or break upon impact compared to other materials.

- Q: What are the common standards and specifications for steel pipes?

- The common standards and specifications for steel pipes include ASTM A53, ASTM A106, API 5L, and ISO 3183. These standards outline the requirements for the manufacturing, dimensions, and mechanical properties of steel pipes used in various industries such as oil and gas, construction, and transportation. Additionally, specific applications may have their own standards and specifications that need to be met for quality and safety purposes.

- Q: What are the different types of steel pipe unions?

- Various industries and applications commonly utilize several types of steel pipe unions. Some of the most frequently used types are as follows: 1. Threaded Union: This union features female threads on both ends, facilitating easy attachment to two male threaded pipes. It ensures a reliable connection that is resistant to leaks. 2. Socket Weld Union: On one end, this union has a socket, while the other end is equipped with a female threaded connection. It is specifically designed for socket welding, where the pipe is inserted into the socket and then welded around the joint, resulting in a robust and long-lasting connection. 3. Butt Weld Union: This specific union is employed for joining two pipes with butt weld ends. It necessitates beveling the pipes and subsequently welding them together, creating a sturdy and permanent connection. 4. Compression Union: Typically used for connecting pipes made of softer materials like copper or plastic, compression unions consist of a compression nut and a compression ring. These components are tightened onto the pipe, ensuring a tight and secure seal. 5. Flanged Union: This union is equipped with flanges on both ends, allowing it to be bolted onto two flanged pipes. Flanged unions are commonly utilized in applications where easy disassembly and reassembly are necessary. 6. Grooved Union: Grooved unions possess grooves on their ends, which are utilized for connecting pipes by inserting them into the grooves and securing them with a coupling. They are often utilized in fire protection systems and other applications where quick installation and easy maintenance are of utmost importance. These examples represent only a fraction of the numerous types of steel pipe unions available. The selection of a union depends on the specific requirements of the application, such as the pipe material, size, and operating conditions. Seeking advice from a professional or consulting industry standards can aid in determining the most suitable union for a particular project.

- Q: Seamless steel pipe and welded pipe what is the difference?

- Identification method: see the inside of the pipe, because the external, will deal with the welded pipe is inside a gap, you can see some, some, is not easy to see, you can slowly by hand touch, or see the specifications are relatively thin, welded pipe

- Q: How do steel pipes handle water hammer?

- Steel pipes can effectively handle water hammer by absorbing the pressure surges caused by sudden changes in water flow. The solid and durable nature of steel helps to dampen the impact and prevent damage to the pipes or other components of the plumbing system. Additionally, steel pipes can be designed and installed with appropriate supports, expansion joints, and water hammer arrestors to further mitigate the effects of water hammer.

- Q: How to make the internal tooth of the steel pipe?

- Compared with the ordinary light pipe, tube can effectively prevent the formation of steam film between the seal and the pipe wall, increase the light disturbance flow inside the tube, the tube wall temperature is more uniform, which can avoid the light pipe damage, and improve the heat transfer efficiency of boiler. The number of thread head of internal thread pipe is 4, 6 head and 8 head according to need. The main materials are 20G, SA210C, T2, T12, 12Cr1MoVG, 15CrMoG, T22, T23 and so on. China needs 2.5~3.0 tons per year of inner thread tube.

Send your message to us

Underground Metal Reinforced PE Spiral Corrugated Pipe for Drainage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords