Ultra High Temperature Insulating Fire Brick - Alumina Bubble Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

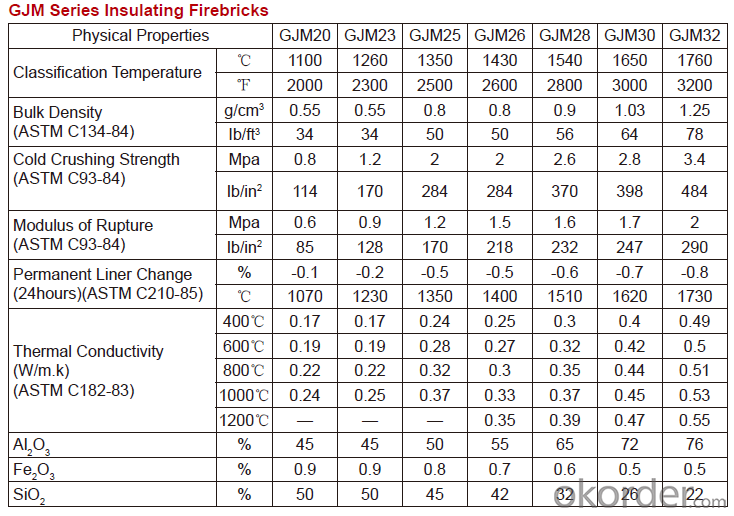

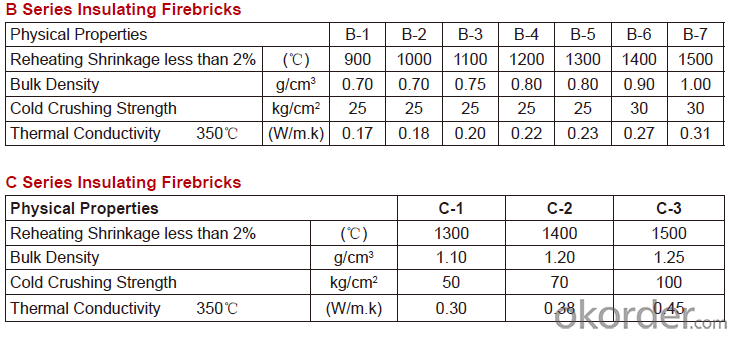

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used for insulation in walls or roofs?

- Insulating fire bricks are primarily designed for high-temperature applications such as furnaces and kilns, not for typical insulation purposes in walls or roofs. While they do provide excellent thermal resistance, they are not structurally suitable or cost-effective for conventional construction. Other insulation materials specifically designed for walls and roofs, such as fiberglass or foam boards, are more appropriate for these applications.

- Q: Refractory bricks, burner bricks, insulation bricks? Is it a kind of thing?

- Not the same thing, refractory bricks and insulation bricks of raw materials, the proportion is not the same. This is the chain of various types of products

- Q: Advantages and disadvantages of wall insulation system?

- The advantages of internal insulation: insulation walls, paint inside the wall, and direct people or other biological contact, in order to ensure human or biological health in insulation coating insulation at the same time, we must first ensure that the paint is non-toxic, no volatile substances.

- Q: Are insulating fire bricks suitable for use in cement plants?

- Yes, insulating fire bricks are suitable for use in cement plants. Insulating fire bricks are made from lightweight refractory materials that are designed to resist high temperatures and thermal shock. These bricks have low thermal conductivity, which means they can effectively insulate against heat transfer. In cement plants, where high temperatures are generated during the production process, insulating fire bricks can be used in various applications. They can be used to line the kiln, where the raw materials are heated to extreme temperatures to produce cement clinker. The insulating properties of these bricks help to reduce heat loss and improve energy efficiency in the kiln. Additionally, insulating fire bricks can be used to line the preheater tower and other high-temperature areas in the cement plant. These bricks provide insulation and protection against the intense heat, helping to prolong the lifespan of the equipment and reduce maintenance costs. Furthermore, the lightweight nature of insulating fire bricks makes them easier to handle and install compared to traditional refractory bricks. This can save time and labor during the construction or repair of cement plant equipment. Overall, insulating fire bricks are a suitable choice for use in cement plants due to their high-temperature resistance, low thermal conductivity, and ease of installation. They can contribute to improved energy efficiency, equipment durability, and cost savings in cement plant operations.

- Q: Are insulating fire bricks suitable for applications requiring low thermal conductivity?

- Yes, insulating fire bricks are suitable for applications requiring low thermal conductivity. Insulating fire bricks are specifically designed to have low thermal conductivity, making them ideal for situations where heat insulation is necessary. These bricks are made from lightweight and porous materials, such as clay and other refractory materials, which provide excellent insulation properties. The porous structure of insulating fire bricks traps air within the material, reducing heat transfer and resulting in low thermal conductivity. This makes them effective in applications such as kilns, furnaces, and other high-temperature environments where minimizing heat loss is crucial. Overall, insulating fire bricks are a reliable choice for applications that demand low thermal conductivity.

- Q: Do insulating fire bricks require maintenance?

- Yes, insulating fire bricks require minimal maintenance. They are designed to withstand high temperatures and are resistant to cracking or crumbling. However, regular cleaning to remove any debris or buildup is recommended to maintain their insulating properties and extend their lifespan.

- Q: What is the water absorption of insulating fire bricks?

- The water absorption of insulating fire bricks is typically low, ranging from 5% to 10%.

- Q: Can insulating fire bricks be used in chimney liners?

- Yes, insulating fire bricks can be used in chimney liners. They are designed to withstand high temperatures and provide insulation, making them suitable for use in chimneys to improve efficiency and prevent heat loss.

- Q: Are insulating fire bricks suitable for use in steel mills?

- Yes, insulating fire bricks are suitable for use in steel mills. Insulating fire bricks have high temperature resistance and excellent thermal insulation properties, making them ideal for lining furnaces and kilns in steel mills. They help to maintain high temperatures while minimizing heat loss, resulting in energy efficiency and cost savings. Additionally, insulating fire bricks also provide protection against thermal shock and chemical corrosion, enhancing the overall durability and longevity of steel mill equipment.

- Q: What is the exterior wall insulation material made of graphite?

- Graphite is polystyrene board, polyurethane graphite plate, from the point of view of building the acceptance specification in the use process, the core index of insulation material is the heat transfer coefficient and safety, by now a large number of glazed hollow bead slurry from the actual situation it seems difficult to ensure the quality of construction materials should be on site workers slurry mixing, finished product the quality gap made out of very large.

Send your message to us

Ultra High Temperature Insulating Fire Brick - Alumina Bubble Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords