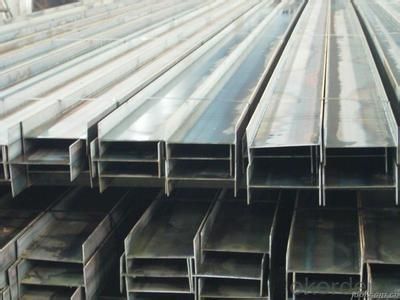

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Details

| Dimensions: | 5#-40#AB | Grade: | Q235,Q345/SS400, SM400A,SM400B | Place of Origin: | China (Mainland) |

| Certificate: | CQC | Model Number: | 5#-40# | Shape: | U Channel |

| Application: | manufacture and fabrication of a broad range of engineered products | Perforated Or Not: | Not Perforated | Standard: | GB,JIS,EN |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as per your request |

| Delivery Detail: | 25-45 days |

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Advantages

Full size

High quality

Prompt shipment

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Specifications

Product | U channel steel | ||

| Standard | JIS AISI ASTM GB DIN BS | ||

| Grade | Q235,Q345/SS400,SM400A,SM400B,SPFC590 | ||

| Size | 50*37*4.5mm---400*104*14.5mm | ||

| Length | 6m,9m,12m,or cut the goods to the clients'request | ||

| Shape | U | ||

| Package | Standard export packing or as per your request | ||

| Application | Construction,shipbuilding,machine-made household industry | ||

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Pictures

- Q: Are steel channels suitable for agricultural applications?

- Yes, steel channels are suitable for agricultural applications. They are strong, durable, and have high load-bearing capacity, making them ideal for constructing farm buildings, fences, and equipment supports. Additionally, steel channels are resistant to harsh weather conditions and provide excellent structural stability, ensuring long-lasting performance in agricultural settings.

- Q: Are steel channels available in custom sizes?

- Yes, steel channels are available in custom sizes. Steel channels are typically manufactured in standard sizes, but many suppliers also offer the option of customizing the dimensions to meet specific project requirements. This allows customers to obtain steel channels in lengths, widths, and depths that are not readily available in standard sizes. Custom-sized steel channels are commonly used in various industries, including construction, manufacturing, and engineering, where precise measurements are crucial for the successful completion of a project. By offering custom sizes, suppliers provide flexibility and ensure that customers can obtain steel channels that perfectly fit their needs.

- Q: Are steel channels suitable for use in the construction of equipment frames?

- Yes, steel channels are suitable for use in the construction of equipment frames. Steel channels, also known as C-channels or U-channels, are commonly used in the construction industry due to their strength, durability, and versatility. They provide excellent structural support and stability, making them ideal for equipment frames. Steel channels are made from high-quality steel, which offers superior strength and load-bearing capacity. This makes them capable of withstanding heavy loads and providing a stable platform for equipment. Additionally, steel channels have excellent resistance to bending, twisting, and warping, ensuring that the equipment frame remains sturdy and reliable. Furthermore, steel channels come in various sizes and thicknesses, allowing for customization to suit specific equipment requirements. They can be easily cut, welded, and shaped to fit the desired frame design. This flexibility in design and construction makes steel channels an attractive choice for equipment frames, as they can be tailored to meet the specific needs of the equipment being supported. In terms of cost-effectiveness, steel channels offer a great value for money. They have a long lifespan and require minimal maintenance, making them a durable and cost-efficient option. Steel is also a recyclable material, making it an environmentally friendly choice for construction projects. Overall, steel channels are highly suitable for use in the construction of equipment frames. Their strength, durability, versatility, and cost-effectiveness make them an excellent choice for supporting and securing equipment in various industries.

- Q: Are steel channels resistant to pests or termites?

- Yes, steel channels are highly resistant to pests and termites. Unlike wood, which is vulnerable to insect infestation, steel channels provide an inhospitable environment for pests. Termites do not feed on steel, as it is not a source of cellulose, which is their primary food source. Therefore, steel channels are an excellent choice for construction projects in areas prone to pest or termite infestations, as they offer long-lasting durability and protection against such issues.

- Q: How do steel channels contribute to building adaptability?

- There are several ways in which the use of steel channels contributes to the adaptability of buildings. To begin with, steel channels play a crucial role in providing structural support and reinforcement. They are utilized in the construction of beams, columns, and trusses, which effectively distribute the weight of the building and ensure its stability. This structural strength allows for greater flexibility in building design and layout, as it permits the creation of larger open spaces and reduces the need for load-bearing walls. This adaptability is particularly important in modern building design, where there is a high demand for open floor plans and flexible spaces. Moreover, steel channels possess exceptional durability and resistance to various environmental factors. They can withstand extreme temperatures, high winds, and seismic activity, making them suitable for construction in diverse locations and climates. This durability is critical for building adaptability, as it guarantees that the structure can endure changes in environmental conditions and remain functional over an extended period. Additionally, steel channels are known for their ease of use and the ability to be easily modified or reconfigured. Their modular nature facilitates simple assembly, disassembly, and modification of building components. This flexibility allows for future expansion or modification of the building without the need for significant structural changes. It also enables the building to adapt to changing needs or functions, such as transforming a commercial office into a residential apartment. Furthermore, steel channels are highly recyclable, making them an environmentally sustainable choice for construction. They can be melted down and reused multiple times without compromising their structural integrity. This recyclability contributes to building adaptability by allowing for the reuse of steel components in different construction projects, reducing waste, and conserving resources. In conclusion, steel channels contribute significantly to the adaptability of buildings by providing structural support, durability, ease of modification, and recyclability. These qualities enable buildings to accommodate changing needs, layouts, and functions, making them versatile and adaptable over time.

- Q: What is the difference between C steel, U steel and channel steel?

- U type steel (hot rolled U steel mine roadway Name: U steel) is English steel like the letter "U" with a cross section, sometimes with a cross section of Japanese letters "better" shape. Main features: large pressure, long support time, easy installation, not easy to deformation and so on. Main uses: mainly used in mine roadway, roadway support, and two times of the tunnel supporting etc.. As the main shape steel for the retractable metal support of tunnel, U steel is widely used at home and abroad.

- Q: What are the different types of hangers used for steel channels?

- There are several different types of hangers used for steel channels, including clevis hangers, u-bolt hangers, pipe hangers, and beam clamps. These hangers are designed to provide support and secure the steel channels in various applications, such as construction, plumbing, and electrical installations. Each type of hanger has its own specific design and mounting method to accommodate different channel sizes and load capacities.

- Q: Can steel channels be customized to specific dimensions?

- Yes, steel channels can be customized to specific dimensions. Steel channels are versatile and can be fabricated to meet specific requirements in terms of width, height, and thickness. This customization is achieved through various manufacturing processes like cutting, bending, and welding. By altering these dimensions, steel channels can be tailored to fit specific applications and structural requirements. Whether it is for construction, machinery, or any other industry, steel channels can be customized to meet the desired dimensions and specifications.

- Q: Can steel channels be used in agricultural applications?

- Indeed, agricultural applications can make use of steel channels. These versatile structural components possess both strength and durability, rendering them highly suitable for diverse uses within the agricultural sector. They can be utilized to construct barns, sheds, and other farm structures, as well as to establish support systems for irrigation, fencing, and enclosures for livestock. Furthermore, steel channels exhibit resistance against pests, rot, and fire, ensuring enduring and dependable support for agricultural operations. Moreover, their capacity to endure heavy loads and unfavorable weather conditions positions them as an ideal choice for applications within the agricultural industry, where strength and durability hold utmost importance.

- Q: What are the different types of corrosion protection for steel channels?

- Steel channels have various corrosion protection methods available, depending on specific requirements and environmental conditions. Some common methods include: 1. Galvanization: A highly popular corrosion protection method for steel channels involves coating them with a layer of sacrificial zinc. This prevents corrosion by corroding the zinc layer instead of the steel. 2. Powder coating: Channels can be protected by applying a dry powder, which is then baked to create a protective layer. This not only offers excellent corrosion resistance but also enhances the channels' aesthetics. 3. Epoxy coatings: Aggressive environments often require the use of epoxy coatings. These create a durable barrier against moisture and chemicals, preventing corrosion of the steel channels. 4. Paint coatings: Cost-effective paint coatings involve applying multiple layers to form a barrier between the metal and corrosive elements in the environment. 5. Hot-dip galvanizing: Immersing steel channels in molten zinc provides a thicker and more durable layer of protection compared to regular galvanization. 6. Cathodic protection: This technique protects steel channels by making them the cathode in a corrosion cell. Channels are connected to a sacrificial anode, such as zinc or magnesium, which corrodes instead of the steel. 7. Stainless steel: Using stainless steel channels is an effective way to prevent corrosion. The high chromium content forms a passive oxide layer on the surface, protecting it from corrosion. To ensure the longevity and durability of steel channels, it is essential to select the appropriate corrosion protection method based on factors such as the environment, expected lifespan, and cost considerations.

Send your message to us

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords