Plastic Tubes Compatible Type A1 Hot Melt Copper Core Ball Valve for Hot and Cold Water Systems 2024

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 100000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details

Material: Plastic

Technics: Injection

Type: Valve

Place of Origin: Zhejiang, China (Mainland)

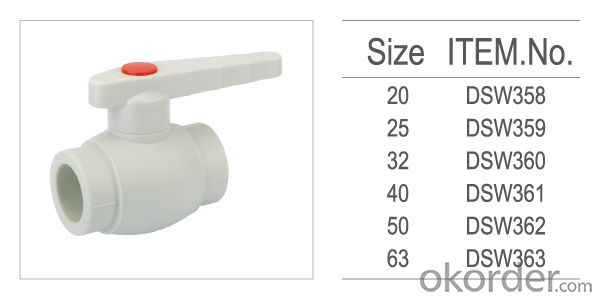

Model Number: DSW358-363

Connection: Welding

Shape: Equal

Head Code: Round

Standard: ISO,DIN,EN,MSS,API,BS,ANSI

Certification: ISO9001,CE

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

FAQ

Q1:How can i get a sample?

A1: You can get samples by communicate with our export sales.

Q2:How long is delivery?

A2:Delivery time will be 30-45 days according to order quantity.

- Q: My bridge had broken and I got someone to make me a new one, but when I reviewed it over, I noticed they moved the plastic tube to the bottom of the violin. Should I not worry about it or have someone fix it?

- Does the bridge have a protective cover glued to it under the string - it's called a parchment? Or does the bridge have an insert in it, usually made from Ebony? If either of these is a yes, you don't need the tube. If the answer was no to both, the tube should probably be there to protect the bridge from the string cutting in. Here is a pic of the two possibilities I've mentioned.

- Q: Are plastic tubes available in flame-retardant options?

- Yes, plastic tubes are available in flame-retardant options. These tubes are specially designed and treated to have a reduced flammability and slow down the spread of fire.

- Q: I'm trying to hang a picture.

- plastic tubes are called raw plugs.... they are for screws. you drill a hole in the wall, and usually the diameter of the hole is too big for the screw thread to bite properly, so hammer one of the plastic tubes into the hole, and then screw in a screw. hey presto it bites solidly and you can hang heavy stuff off it.

- Q: there is a plastic tube that goes from the bathroom sink(strainer) into the wall. It seems to be clogged. How do I go about fixing this if it is leaking?

- It should be about an inch and a quarter in diameter. At the wall there is what looks like a big nut. Take a large pliers and turn counterclockwise and take it loose. Take your hand, touch that nut and go back wards toward the sink and you will find another. Take that one off too, counterclockwise. Be sure to have a small bucket under the sink since you will loose some water. Take the plastic piece to the hardware store, buy new gaskets with it and put it back on. Do not over tighten,

- Q: ive been spending a fortune lately on my hamsters..so my partners asked me to stop buying them things for a couple of weeks..but i really want some tubes for my hamsters anybody got some old ones they dont want anymore..that could give me for cheap??

- go to a hard ware store and find a plastic tube for plumbing i bought 5 of them for 50 cents each. it was cheap and they last a long time, they are also too hard to chew so they cant eat them, that way you wont need to keep buying tunnels and you can just save up change.

- Q: Can plastic tubes be used for food and beverage applications?

- Yes, plastic tubes can be used for food and beverage applications.

- Q: Can plastic tubes be used for outdoor applications?

- Yes, plastic tubes can be used for outdoor applications.

- Q: the tubing , on the door, where water depenses is cracked. how do I replace the tubing?

- Wow! Are you wanting to replace all the tubing inside the door? This can be a very difficult if not impossible job to accomplish. There are countless components that require removal to expose all the tubing for replacement. Although you just ask about the door, the tubing going to the icemaker is embedded in the permanent foam insulation in the cabinet casing. It is also installed in the foam inside the door. They do this to prevent the water inside the tubing from freezing. Most water dispensers are located in the freezer side door. If you just want to replace the short stub of tubing that the water passes through at the dispenser, you should be able to cut off the part that is cracked or split and glue a short food grade piece of tubing on to it using food grade adhesive (available at restaurant supply stores). (Use a short collar of the next larger diameter tubing to join the two pieces.Also available at the supply store.) Good luck!

- Q: What types of closures are available for plastic tubes?

- There are several types of closures available for plastic tubes, including screw caps, flip-top caps, snap-on caps, pump dispensers, and flip-top snap caps.

- Q: I don't need the candy, just the tubes. Do you know where I can buy them in bulk , and at a reasonable price?

- I have no idea, but it is a very specific question... I don't even know what sandy candy is...

Send your message to us

Plastic Tubes Compatible Type A1 Hot Melt Copper Core Ball Valve for Hot and Cold Water Systems 2024

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 100000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords