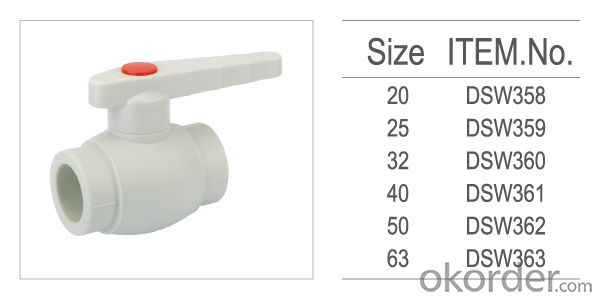

PPR type A1 hot melt copper core ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 100000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details

Material: Plastic

Technics: Injection

Type: Valve

Place of Origin: Zhejiang, China (Mainland)

Model Number: DSW358-363

Connection: Welding

Shape: Equal

Head Code: Round

Standard: ISO,DIN,EN,MSS,API,BS,ANSI

Certification: ISO9001,CE

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

FAQ

Q1:How can i get a sample?

A1: You can get samples by communicate with our export sales.

Q2:How long is delivery?

A2:Delivery time will be 30-45 days according to order quantity.

- Q:I mean, like filling a plastic tube from end to end with mercury, sealing it with caps that allow contact points at either end, and then wrapping the tubing around a ferrite core, and adding current. Would this function just like any other coil?

- Yes it would, although I'm not sure how the plastic tubing would affect the current. If the type of plastic used is an insulator, it may affect performance of the magnet. Some plastics conduct electricity though, and there's no reason they wouldn't work.

- Q:What are the common uses for plastic tubes in construction?

- Plastic tubes are commonly used in construction for various purposes such as electrical conduit, plumbing pipes, drainage systems, ventilation ducts, and cable management.

- Q:Can plastic tubes be used for storing pharmaceuticals?

- Yes, plastic tubes can be used for storing pharmaceuticals.

- Q:How do you label plastic tubes?

- Plastic tubes can be labeled using various methods such as adhesive labels, heat shrink sleeves, direct printing, or laser etching, depending on the tube material and intended use.

- Q:i would like make my own fishing floats,but cant find things i need. the reed,plastic tube, screw in eyes?

- r u on an island? like in that movie Castaway?

- Q:How do you prevent plastic tubes from cracking under pressure?

- To prevent plastic tubes from cracking under pressure, several measures can be taken. Firstly, using a high-quality plastic material with good tensile strength and flexibility is crucial. Additionally, reinforcing the tubes with additives or fillers that enhance their strength and resistance can be beneficial. Maintaining proper installation techniques, such as avoiding sharp bends and ensuring adequate support, is also important. Lastly, regular inspections and maintenance to identify any signs of wear or damage can help prevent cracks from developing or worsening over time.

- Q:does it matter where you pur the fluid and how much should be poured in my vanhave a radiator caop and then like a long plastic tube that goes down to the engine and says coolant on it...where do i pour the antifreeze??

- Make absolutely sure you replace the radiator cap with an AC Delco closed system radiator cap. The correct part # for this cap is listed in your glove compartment manual in the specification pages. A closed system radiator cap has a large rubber gasket covering the inverted shell spring facing you as you look inside it. From your description the gasket is missing or the pressure rating is incorrect. Also, make sure the hose that run from the coolant recovery tank to the the small outlet at the top of the cap neck is free and clear. This allows the the radiator to push coolant back inside the reservoir when the pressure exceeds the pressure rating on top of the radiator cap. As the engine and cooling system looses heat when you turn off the motor a secondary check valve in the center of the radiator cap opens allowing the coolant to be pulled under vacuum back into the radiator, block and cylinder heads. The whole plan of this system is to evacuate all air bubbles from the coolant making the system more efficient.

- Q:The difference between metal hose and corrugated plastic pipe

- Some corrosive, high-pressure liquids, gases, etc can be taken. Plastic corrugated pipe is also a wide range of more common for drainage.

- Q:Are plastic tubes suitable for hydroponic systems?

- Yes, plastic tubes are suitable for hydroponic systems. They are commonly used as a cost-effective and versatile option for transporting water and nutrients to the plants in a hydroponic setup. Plastic tubes are lightweight, easy to install, and resistant to corrosion, making them a practical choice for hydroponic gardening.

- Q:Do plastic tubes have any limitations in terms of moisture resistance?

- Yes, plastic tubes have limitations in terms of moisture resistance. While many plastic tubes are designed to be moisture resistant, prolonged exposure to moisture can lead to degradation of the material, compromising its effectiveness. Additionally, some types of plastics may not be suitable for use in highly humid or wet environments as they may absorb moisture or become brittle. It is important to consider the specific plastic material and its intended application when assessing its moisture resistance capabilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR type A1 hot melt copper core ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 100000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords