Tower Crane Full Range from China Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

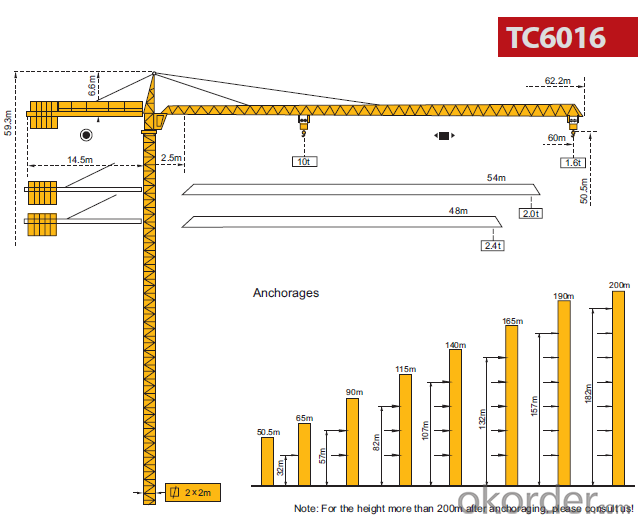

Structure of Tower Crane Description

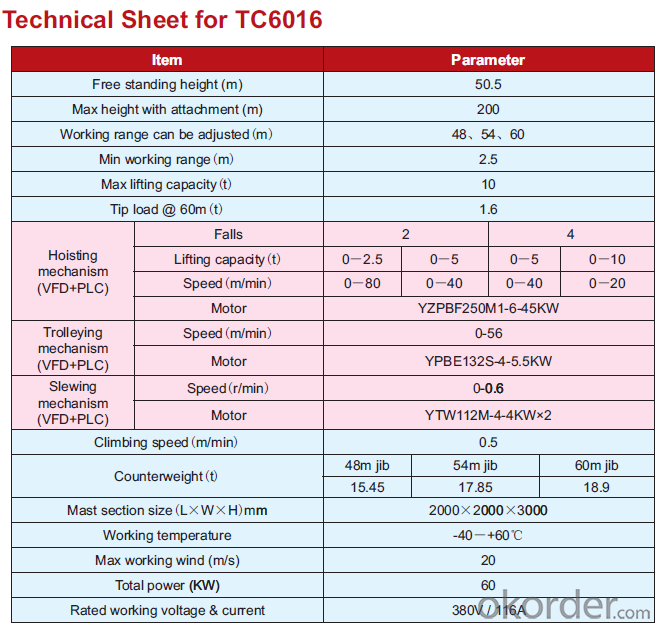

Feature: Tower Crane Condition: New Application: Construction Max.Lifting Load: 10T Max Tip Load:1.6T Independent Height:50.5M

Max Lifting Height: 200M Span: 60m Certification: CE,ISO

Place of Origin: China(Mainland) Model Number: TC6016

Packaging & Delivery of Tower Crane

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Feature of Tower Crane

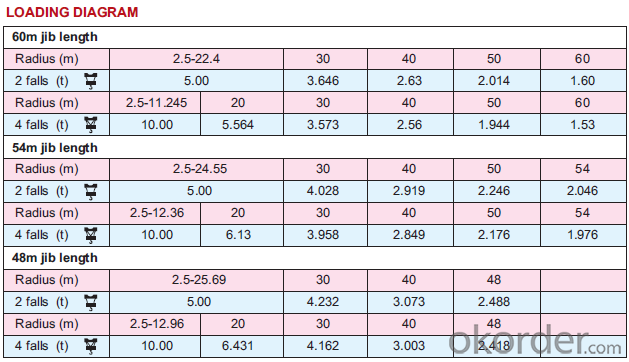

● Max. working range 60m, tip lifting weight 1.6T and Max. lifting weight 10T.

● Slewing mechanism and trolleying mechanism equipped with VFD technical control, stable and reliable,can provide stepless speed regulation.

● Outstanding in working efficiency, operating speed and stability. Reduce future maintenance cost.

Tower Crane TC6016 Specifiction

FAQ of Tower Crane

Q: What kinds of tower crane are available now?

A: Four main categories: normal tower crane with cat head, internal climbing tower crane, top less tower crane and luffing tower crane.

Q: What kind of steel used for tower crane?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: Your tower crane is similar to Potain or Liebherr type?

A: We could develop any type of tower crane as per clients’ requirements if the clear information is provided. Originally, our tower crane design is based on Liebherr; but now, we not only introduced Potain design; but also developed special tower crane according to the market needs such as TC5013A with panel mast section. In addition, we also produce some models same as Potain original model, such as F0/23B, H3/36B and etc.

- Q: I have a problem in discovering the breakdown in the tower crane control panel. If you can give me a procedure to follow the problem in the control panel.

- Generally tower cranes have their electrical panels at the ground floor. Troubleshooting in the tower crane is not different to any other electrical system. First check the power circuit healthiness--switches,fuses,contactors and then go for control circuit. The cranes have few additional interlocks for excessive forward movement, extra long travel etc. Just go through the drawing and u will get the problem solved

- Q: Where can I get the tower crane manufacturing permit?

- This is the permit of the Bureau of quality supervision

- Q: from the legend of sleepy hollow, his background, characater, personality, life etc.

- uhh...by reading sleepy hollow?

- Q: i have a 100 ton american crawler crane. how do i calculate the psf, for this equipment.

- Not sure what you are asking exactly... Are you saying that you have a crane with a capacity of 100 tons and you want to know the pressure on the soil where the crane is positioned? In this case, you take the capacity (in pounds) plus the weight of the crane (in pounds) then divide their sum by the area of the tracks on the crane (in square feet). This will result in pounds per square foot or psf as you wrote above. These are example estimates, they may not be anywhere near the correct answer, this is simply how to do the calculation. Assumed Capacity 100 ton = 200,000 lbs. Assumed Weight 105 ton = 210,000 lbs. Assumed Area of Track = 200 square feet Note: 1 U.S. ton = 2,000 pounds = 2,000 lbs. 410,000 lbs / 200 square feet = 2,050 psf There's a start, now you just need to find out how much it actually weighs and how long and wide the tracks are to get the area of the track on the ground. I hope that answers the question you were asking.

- Q: my HSAP prep teacher wants us to find instructions on how to make an oragami crane.She said that it has to be less than 24 steps.I have looked on the internet and I cannot find anything.I need this by tomorrow.Please help!

- Start with a square piece of paper. You got that? Fold the paper corner to corner to get a large right triangle, and fold it corner to corner again to get a smaller triangle. You got that ,or did I lose you. Open the paper, and you will see a big X. Never mind the X. We will come back to it. Now fold the paper side to side to get a rectangle, and fold the two SHORT SIDES to the X fold. Open and do the other two by repeating what you just did. Open the paper FLAT. You can now see a 4 pointed star. Along the four sides of the square, push down on the perimeter of the star to make the star come up. Fold down until you have a flat KITE. Make sure you have 2 flaps on each side. What you are looking at now is one wing, and the other one is in the back. The neck and head are inside the wings. Pull them out half way to expose them. Fold one side at the tip to make a head. If you did everything correctly, and hold under the neck with one hand and pull the tail with the other hand, the crane should flap its wing. Write back if you need more help.

- Q: How to distinguish self lifting tower crane with counterweight and lifting tower crane without counterweight

- With the weight of the tower crane is mainly ordinary tower cap tower crane, tower crane and tower crane type, is made of concrete counterweight pieces of the balance arm, is also useful for iron making, but relatively rare.The tower crane without counterweight is mainly a city quick loading tower crane. It is characterized by the absence of balance arm, and it is impossible to have counterweightThe layman can not tell the can see the appearance, there are long steel structure before and after the weight of the tower body, and no weight of the tower body with only one steel structure (i.e. jib crane, structure)

- Q: What kind of personnel should be installed for the tower crane installation and disassembly?

- According to GB specifications:2.0.3 the installation and disassembly of tower cranes shall be provided with the following personnel:1. The project and the safety supervisor and the mechanical management personnel who have the safety inspection certificate;2, with special construction operation qualification certificate of construction, lifting machinery, installation, demolition workers, lifting signal workers, lifting drivers, cable operators and other special operations personnel.And an electrician.

- Q: I'm trying to workout the best height of a truss for a ship-to-shore container crane project. The crane will have a 65m outreach, 18m center section and 15m backreach. I was thinking in the region of 2m-3m truss height.Any input would be great.Thanks

- Jimmy: The American Society of Mechanical Engineers (ASME) produces design standards for many types of cranes: see the link below. Many crane owners, licensing and governmental authorities having jurisdiction over cranes require design, fabrication and testing to ASME standards.

- Q: when a skyscraper is done being built, how does the crane come down?

- In pieces, section by section, and then the base is taken out by Helicopter. Or at least that is how I would do it.

- Q: How much is a team of 40 tower crane

- Tower crane rental generally do not rent pricing, can not count number, not today is installed, removed tomorrow!Usually on a monthly basis, with or without use!

Send your message to us

Tower Crane Full Range from China Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords