Torch Applied Concrete Roof Modified Bitumen SBS Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick DetailsType:

Waterproof Membrane, Waterproof membrane Place of Origin: China (Mainland)

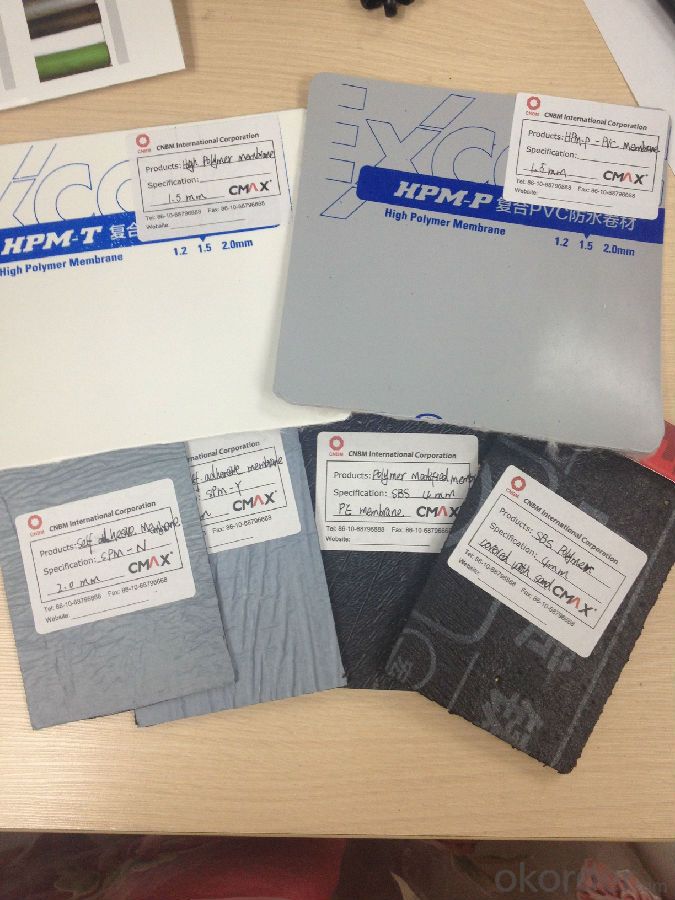

Surface film: PE, SAND, SCHIST,aluminum Thickness: 2.0mm~5.0mm Length: 10.0m

Width: 1.0m Usage: waterproofing for roof, understand,etc

Packaging & DeliveryPackaging Details:

10 sq.m./roll export package or as requirment

Delivery Detail: 15 days after receipt of deposit.

Specifications3mm SBS modified bitumen waterproof membrane

1) 2--5mm

2) Base:PY/G

3) Surface:PE / S / M / Al

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. start application till it is dry.< span="">

2. Application Method:

Heating the bottom surface of membrane and the roof deck surface by flam spray gun or other suitable appliances till the asphalt start to melt(not flowing), then spread. Using roller to compact the membrane so that it can firmly adhere to the base surface. The overlap on the long side should be 100mm and the short side should be 150mm.

·

SBS / APP asphalt waterproof membrane, bituminous waterproof membrane

1. Membranes should be stored under dry and ventilated conditions.

2. Different types of membranes must be piled separately.

3. Under usual condition, storage period is one year since production date.

4. Membrane roll should be put vertically during transportation. It should be kept away

from sunshine and rainwater.

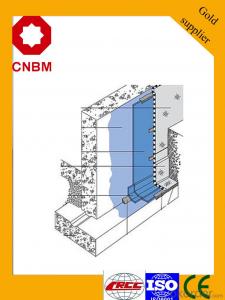

Installation Sketch point

Clean the substrate using broom or high pressure dusty cleaner.

Apply primer

Heat the membrane bottom using a high temperature flame gun.

Push forward while the primer and membrane oil melted

Use a roller to push hard the membrane surface to ensure it stick firmly

1.Base processing: the base surface musts be clean,solid,level,dry;no grit,rift and loosing dust. For a large recess, fill it with cement mortar and then level it. Remove the protrusion and clean dust If working on base slab or lateral face,water lowering should be done.

2.Painting primer before laying the membrane, clean the dust on the surface of concrete base with dust catcher or dust-blower; then paint entirely with treatment agent of DY primer for waterproofing(for purpose of dust consolidation and high adhesive effect).

Why choose us?

1,Honest supplier to the worldwide buyers

2,Factory, direct supplier, competitive price

3,Know how to control the costing with 30 years experience

4,Warm and friendly service and guide

5,China National Standard GB/18242-2008

6,3 shifts workers for 24hrs production, high capacity

7,Small and big orders are welcome from the worldwide

8, 24 hours service for you

FAQ

1,Q:Are you a factory or trading company?

A:We are a factory

2,Q:Where is your factory located?How can i visit there?

A:Our factory is located in Zhengzhou City,Henan Province,China,about 2 hours plane from Shanghai,Guangzhou ect.We can pick you up at the airport.All our clients,from home or abroad,are warmly welcome to visit us!

3,Q:How can i get some samples?

A:We are honored to offer you Free samples.

4:Q:How does your factory do regarding quality control?

A:Quality is priority.King Waterproof Material people always attach great importance to quality controlling from the every beginning to the very end.Our factory has gain ISO9001:2008,ISO4001:2000 ,CEC And LANxess Testing

- Q: Are waterproofing membranes resistant to high temperatures?

- The resistance of waterproofing membranes to high temperatures may vary depending on the specific material utilized. Certain waterproofing membranes are specifically engineered to endure high temperatures while retaining their effectiveness and integrity. These membranes often comprise materials like modified bitumen or synthetic rubber, which possess properties that enable them to withstand elevated temperatures. Nevertheless, it should be noted that not all waterproofing membranes possess resistance to high temperatures. Some membranes constructed from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is imperative to refer to the manufacturer's specifications and guidelines to ensure that the selected waterproofing membrane is appropriate for the intended application and can endure the expected temperature conditions.

- Q: Are waterproofing membranes suitable for tunnels?

- Yes, waterproofing membranes are suitable for tunnels. Tunnels are often subjected to high water pressure from the surrounding soil and groundwater, making them vulnerable to water ingress. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively prevent water from entering the tunnel structure. These membranes are typically made of durable materials such as bitumen, PVC, or EPDM rubber, which are resistant to water penetration. They are applied to the tunnel walls and ceiling to create a continuous, impermeable layer that keeps the tunnel dry. The membranes are also flexible, allowing them to accommodate any movement or settlement of the tunnel without compromising their waterproofing integrity. In addition to preventing water infiltration, waterproofing membranes also offer other benefits for tunnels. They can protect the tunnel structure from corrosion caused by water and chemicals, prolonging its lifespan. They can also help to improve the indoor air quality within the tunnel by preventing the growth of mold and mildew, which thrive in damp environments. Furthermore, waterproofing membranes can be customized to suit different tunnel conditions. For example, in tunnels that are exposed to high levels of hydrostatic pressure, reinforced membranes with higher tensile strength can be used to withstand the added stress. Additionally, membranes with enhanced fire resistance properties can be utilized in tunnels where fire safety is a concern. Overall, waterproofing membranes are a reliable and effective solution for ensuring the durability, safety, and longevity of tunnels by providing a robust barrier against water ingress.

- Q: Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Yes, a waterproofing membrane is generally resistant to gasoline and other petroleum-based substances.

- Q: Where can waterproofing membranes be used?

- Waterproofing membranes have a wide range of applications across different industries. They are commonly utilized in various settings, including: 1. Building and construction: In the construction industry, waterproofing membranes are frequently employed to safeguard structures like basements, roofs, and foundations from water infiltration and subsequent damage. They effectively shield buildings against moisture-related problems such as leaks, mold formation, and deterioration. 2. Civil engineering: Waterproofing membranes are essential in civil engineering projects like tunnels, bridges, and dams to ensure water resistance and prevent water penetration. By keeping these infrastructures dry and protected, they help maintain their structural integrity. 3. Landscaping: When it comes to landscaping projects, waterproofing membranes are commonly used to prevent water from seeping into the soil and causing erosion. They are particularly useful in retaining walls, garden beds, and underground structures, as they contribute to the stability and longevity of the landscape. 4. Transportation: The transportation industry benefits from the application of waterproofing membranes, especially during the construction of roads, highways, and parking lots. By safeguarding the underlying layers from water damage, which can lead to cracks and potholes, they extend the lifespan of transportation infrastructures. 5. Industrial facilities: Many industrial facilities, such as factories, warehouses, and chemical plants, require waterproofing to protect their structures and equipment from water damage. Waterproofing membranes serve as barriers against water intrusion, preventing corrosion and preserving the longevity of these facilities. In summary, waterproofing membranes are versatile solutions that are indispensable in various sectors where water resistance and protection against moisture-related damages are crucial. They play a critical role in preserving the integrity and longevity of structures and infrastructures, thus preventing costly repairs and ensuring a safe and functional environment.

- Q: Does a waterproofing membrane prevent water vapor transmission?

- Yes, a waterproofing membrane is designed to prevent both liquid water and water vapor from penetrating through a surface. It acts as a barrier that blocks the movement of moisture, including water vapor, thus preventing water intrusion and potential damage to the underlying structure. Waterproofing membranes are commonly used in various applications such as roofs, basements, and bathrooms to ensure the integrity and durability of the building envelope.

- Q: Can a waterproofing membrane be used in swimming pools?

- Yes, a waterproofing membrane can be used in swimming pools. In fact, it is a common practice to use waterproofing membranes in the construction or renovation of swimming pools to prevent water leakage. These membranes are specifically designed to create a barrier against water penetration, ensuring that the pool remains watertight and free from leaks. The membranes are typically made from durable materials such as PVC, EPDM, or polyurethane, which are resistant to water, chemicals, and UV rays. Additionally, the membranes are flexible and can easily adapt to the shape and contours of the pool, providing a seamless and long-lasting waterproofing solution.

- Q: Can a waterproofing membrane be used on retaining walls?

- Using a waterproofing membrane on retaining walls is possible. Retaining walls often face moisture and hydrostatic pressure, which can result in water infiltration and structural decay. By applying a waterproofing membrane to the retaining wall, water penetration can be prevented, shielding the wall from moisture-related harm and extending its lifespan. The membrane acts as a barrier, stopping water from seeping into the wall and causing problems like efflorescence, cracks, or erosion. It is crucial to select a waterproofing membrane that is designed specifically for below-grade applications and can withstand the pressure exerted by the soil being retained. Moreover, proper installation techniques and suitable drainage systems should be taken into account to ensure the effectiveness of the waterproofing membrane on retaining walls.

- Q: Can a waterproofing membrane be used on precast concrete block surfaces?

- Yes, a waterproofing membrane can be used on precast concrete block surfaces. It helps to prevent water penetration and protects the structure from potential damage caused by moisture.

- Q: How does a waterproofing membrane handle soil movement and settlement?

- Soil movement and settlement are effectively managed by a waterproofing membrane through various mechanisms. Initially, it functions as a barrier between the structure and the soil, thereby preventing water intrusion and minimizing the impact of soil movement on the building. To address soil movement, the membrane exhibits flexibility and elasticity. This enables it to adapt to minor soil shifts and settlements without experiencing cracks or tears. By flexing in conjunction with the movements, the membrane preserves its integrity and sustains its waterproof seal. Moreover, the waterproofing membrane frequently incorporates reinforcements like polyester or fiberglass to enhance its strength and resistance to soil movement. These reinforcements assist in distributing the stress caused by soil settlement across a larger area, thereby reducing the risk of membrane damage. Another crucial consideration is the proper installation and anchoring of the membrane to the structure. This ensures that it remains securely in place even when the surrounding soil moves. Consequently, the membrane avoids shifting or detaching, which may compromise its effectiveness and result in water infiltration. Furthermore, some waterproofing membranes possess self-healing properties. This means that if the membrane sustains punctures or damage due to soil movement, it can automatically seal the breach to prevent water from entering. This self-repairing capability provides an additional layer of protection against damage induced by soil. Overall, a correctly installed and well-maintained waterproofing membrane is specifically designed to withstand soil movement and settlement. Its flexible nature, reinforcements, secure anchoring, and potential self-healing ability enable it to effectively manage these challenges and maintain its waterproofing capabilities over an extended period of time.

- Q: Can a waterproofing membrane be used for chemical storage facilities?

- Yes, a waterproofing membrane can be used for chemical storage facilities. Waterproofing membranes are designed to create a barrier against water and moisture, and they can also provide protection against chemical spills and leaks. These membranes are typically made from durable materials such as PVC or EPDM, which have excellent resistance to various chemicals. Additionally, waterproofing membranes can be applied to various surfaces including concrete, metal, and even existing chemical storage tanks. By using a waterproofing membrane, the facility can prevent water ingress, minimize the risk of corrosion, and ensure the integrity of the chemical storage area. It is important to select a waterproofing membrane that is specifically designed and tested for chemical resistance to ensure optimal performance and safety in such facilities.

Send your message to us

Torch Applied Concrete Roof Modified Bitumen SBS Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords