Tinplate for Container Making made by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

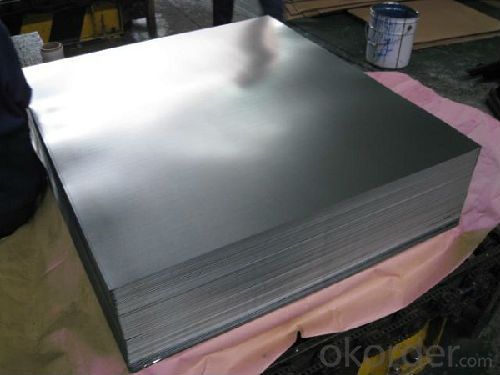

Tinplate for Container Making made by CNBM:

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Description:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

CNBM Introduction

China National Building Materials Group Cooperation, as a leading state-owned enterprise with 3 billion USD and 40,000 staff in China, CNBM was established in 1984 under the administration of the state-owned Assets Supervision and Administration commission of the State Council. There are over 300 surbordinate factories and companies in our group; 2 public listed companies in Hong Kong, 4 Public listed companies in China mainland; 11 publicly listed companies in which CNBM has a substantial percentage of shares. The business scope of CNBM covers from Manufacturing and sales of building materials to scientific research and design, engineering, import and export trading.

On July 7th, 2011, Fortune Magazine established Fortune Global 500 ranking on its website, and CNBM Group was listed for the first time, with a ranking of 485.

CNBM Branch Offices

In order to promote the business connection, CNBM has established branches and offices in lots of foreign countries, such as USA, GERMANY, UAE, SAUDI ARABIA, IRAN, JORDAN, LIBIA,ETHIOPIA, INDONESA, INDIA,VIETNAM,RUSSIA,KAZAKHSTAN. It is very helpful for the communication and after- sale services.

- Q: How is tinplate affected by exposure to light?

- Tinplate is not significantly affected by exposure to light, as it is a durable material that does not undergo any noticeable changes or degradation when exposed to light.

- Q: What are the different coating options for tinplate?

- Some of the different coating options for tinplate include tin-free steel (TFS), electrolytic tinplate (ETP), and tin coating with different grades or thicknesses.

- Q: Is tinplate safe for food contact?

- Yes, tinplate is safe for food contact. It is widely used in the packaging industry for food and beverage cans as it provides a protective barrier that prevents contamination and preserves the quality and safety of the food inside.

- Q: What are the main factors influencing the demand for tinplate?

- The main factors influencing the demand for tinplate include the growth of the packaging industry, consumer preferences for canned food and beverages, economic conditions, and government regulations on food safety and packaging standards.

- Q: How is tinplate recycled and what are the benefits of recycling?

- Tinplate is recycled through a process called "metal reclamation," which involves collecting and separating tin-coated steel from other materials. The tin coating is removed, and the steel is melted down and used to produce new tinplate products. The benefits of tinplate recycling are numerous. Firstly, it conserves natural resources by reducing the need for mining and extracting raw materials. Additionally, recycling tinplate reduces energy consumption and greenhouse gas emissions associated with the production of new tinplate. Moreover, recycling tinplate helps minimize waste disposal in landfills, which reduces environmental pollution and conserves landfill space. It also contributes to the circular economy by promoting the reuse of materials and extending the lifespan of tinplate products. Overall, tinplate recycling is a sustainable practice that brings economic, environmental, and social benefits.

- Q: Can tinplate be used for electrical enclosures?

- Yes, tinplate can be used for electrical enclosures. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against corrosion. This makes it a suitable material for electrical enclosures as it ensures durability and helps maintain the integrity of the enclosed electrical components. Additionally, tinplate is relatively lightweight and cost-effective, making it a popular choice for various industrial applications, including electrical enclosures.

- Q: Can tinplate be used for packaging of corrosive substances?

- No, tinplate is not suitable for packaging corrosive substances as it can react with the corrosive materials and corrode, leading to potential contamination and compromised packaging integrity.

- Q: What are the main challenges in tinplate printing?

- The main challenges in tinplate printing include achieving consistent and accurate color reproduction, managing ink adhesion on the curved and smooth surface of tinplate, preventing smudging or scratching during handling and transportation, and ensuring durability and resistance to corrosion. Additionally, maintaining high efficiency and productivity in the printing process while adhering to environmental regulations is also a significant challenge.

- Q: How does tinplate compare to aluminum packaging?

- Tinplate and aluminum packaging have their own distinct advantages and disadvantages. Tinplate is known for its superior strength and durability, making it ideal for preserving the contents of cans. It is also corrosion-resistant, providing a longer shelf life for canned products. On the other hand, aluminum packaging offers excellent lightweight properties, making it more convenient for transportation and reducing shipping costs. Additionally, aluminum is a better barrier to moisture, light, and oxygen, ensuring better product protection. Ultimately, the choice between tinplate and aluminum packaging depends on the specific needs and requirements of the product being packaged.

- Q: The composition of tinplate?

- The name "tinplate" is not exact. Therefore, in 1973, when the Chinese tin plate meeting was called "tinplate", the official document no longer used the name "tinplate".

Send your message to us

Tinplate for Container Making made by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 400000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords