Tin Free Steel - TFS SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

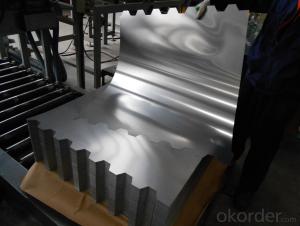

Tin Free Steel (TFS)

Is also known as chromed steel, as it is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.This steel product was developed to meet economic requirements, and excels tinplate in paintability, paint adhesion, and economy. It is widely used for making beverage cans and 18-liter cans. It is also used for making photographic film cases and as a protective material for optical fiber cables.

Our TFS Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Material: MR,SPCC

Thickness:0.15mm - 0.45mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

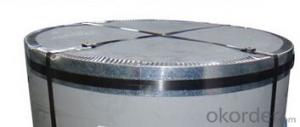

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Oil: DOS

Surface: Finish,bright,stone,matte,silver

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Both Prime and Second Quality Are Available!!!

- Q: What are the main factors affecting tinplate coil surface finish?

- The main factors affecting tinplate coil surface finish include the quality of the raw materials used, the cleanliness of the production environment, the precision of the manufacturing process, and the level of smoothness and cleanliness of the coating applied to the tinplate.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that prevents corrosion and rusting. The tin layer acts as a barrier, shielding the underlying metal from the corrosive effects of saltwater and other environmental factors, thereby increasing the longevity and durability of the equipment in marine environments.

- Q: How does tinplate perform in terms of tamper-evident features?

- Tinplate performs exceptionally well in terms of tamper-evident features. Its inherent strength and durability make it difficult to tamper with or manipulate without leaving clear signs of tampering. Additionally, tinplate can be customized with various tamper-evident mechanisms such as seals, closures, or indicators, further enhancing its reliability as a tamper-evident packaging material.

- Q: How does tinplate contribute to the overall versatility of packaging?

- Tinplate contributes to the overall versatility of packaging due to its inherent properties such as strength, durability, and corrosion resistance. It can be easily shaped into various forms and sizes, making it ideal for packaging different products. Tinplate also provides excellent protection against moisture, oxygen, and light, ensuring the safety and longevity of the packaged goods. Additionally, its compatibility with different printing techniques allows for attractive and informative designs, enhancing the overall appeal of the packaging.

- Q: How does tinplate handle exposure to different atmospheric conditions?

- Tinplate generally handles exposure to different atmospheric conditions quite well. Its corrosion resistance, thanks to the tin coating, helps protect the underlying steel from rusting and other forms of degradation. However, extreme conditions such as high humidity, acidic environments, or prolonged exposure to saltwater may still pose some risk. In such cases, additional protective measures like coatings or proper maintenance are recommended to ensure the tinplate's longevity.

- Q: How does tinplate packaging contribute to product protection against light?

- Tinplate packaging contributes to product protection against light by providing a highly effective barrier that prevents light from reaching the product. The tin coating on the steel substrate acts as a reflective layer, reducing the amount of light transmission. This helps to shield the product from harmful UV radiation and other forms of light that can cause degradation, discoloration, or spoilage. Additionally, tinplate packaging can be further enhanced with additional protective coatings or lacquers that provide an additional layer of defense against light exposure, ensuring the product remains intact and protected.

- Q: How does tinplate contribute to the convenience of pet care products?

- Tinplate contributes to the convenience of pet care products by providing a durable and lightweight packaging option that helps preserve the quality and freshness of the products. It is also easily recyclable, ensuring sustainability while offering a convenient solution for pet owners.

- Q: How is tinplate used in the beverage industry?

- Tinplate is commonly used in the beverage industry for packaging purposes, such as cans for carbonated drinks, fruit juices, and other beverages. The tin coating on the steel sheet provides a protective barrier, preventing corrosion and maintaining the quality and taste of the beverage. Additionally, the versatility of tinplate allows for various shapes and sizes of cans, making it a popular choice for beverage manufacturers.

- Q: Can tinplate be used for microwave-safe packaging?

- No, tinplate cannot be used for microwave-safe packaging as it is not suitable for microwave heating.

- Q: How is tinplate corrosion resistant?

- Tinplate is corrosion resistant due to the protective layer of tin that is electroplated onto the surface of the steel. This tin layer acts as a barrier, preventing oxygen and moisture from coming into direct contact with the steel, thereby reducing the risk of corrosion.

Send your message to us

Tin Free Steel - TFS SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords