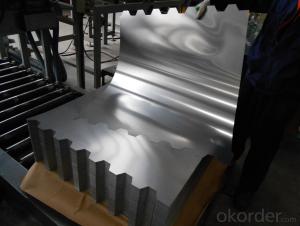

TFS/Tin Free Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications&Information:

Annual capacity: | 12 0000 MT/ year |

Operate standard: | JIS G 3315、GB24180 |

Base plate: | SPCC/MR |

Thickness : | 0.15mm~0.36mm |

Width: | 520mm~950mm |

Length: | 1018mm;828mm;coil;or per your requirement |

Coating | 80~100mg/㎡ |

Temper : | T2,T2.5,T3,T3.5,T4,T5,DR-8,DR-9 |

Finish : | bright / matte/stone |

Packing: | plastic film, anti-rust paper,galvanized iron cover |

Loading : | 20f container with Max weight 25 Ton |

Shipping time: | 30~60 days after the receipt of buyer’s deposit |

Payment : | L/C or 30% TT in advance,70% against copy B/L |

MOQ: | 50 MT |

- Q: What are the factors that affect the price of tinplate?

- The factors that affect the price of tinplate include the cost of raw materials such as tin and steel, supply and demand dynamics in the market, production and manufacturing costs, currency exchange rates, trade policies, and economic factors such as inflation and global economic conditions.

- Q: How is tinplate coated with protective lacquer?

- Tinplate is coated with a protective lacquer through a process called electrostatic spraying. The tinplate is first cleaned and degreased to ensure proper adhesion of the lacquer. Then, the lacquer is applied to the tinplate using an electrostatic spray gun, which charges the lacquer particles and attracts them to the metal surface. This creates a uniform and durable coating that provides protection against corrosion and enhances the tinplate's overall appearance.

- Q: Can tinplate packaging be used for personal care products?

- Yes, tinplate packaging can be used for personal care products. Tinplate is a durable and versatile material that provides excellent protection for various products, including cosmetics, lotions, and other personal care items. Its ability to resist corrosion and maintain the product's quality makes it a suitable choice for packaging in the personal care industry.

- Q: What is the average lifespan of tinplate products?

- The average lifespan of tinplate products can vary depending on various factors such as the quality of the tin coating, the usage conditions, and proper maintenance. However, on average, tinplate products can last for several years to decades if they are well-maintained and not exposed to extreme conditions or corrosive environments.

- Q: Can tinplate be used for packaging of organic products?

- Yes, tinplate can be used for packaging of organic products. Tinplate is a type of steel coated with a thin layer of tin, providing excellent protection against corrosion and ensuring food safety. It is widely used in the packaging industry, including for organic products, as it is considered a safe and sustainable packaging material.

- Q: What are the limitations of printing on tinplate?

- There are several limitations to consider when printing on tinplate. First, tinplate is not a very smooth surface, which can affect the quality and resolution of the printed design. Secondly, tinplate is prone to corrosion, so special coatings or treatments may be required to ensure the longevity of the print. Additionally, tinplate is a rigid material, making it more challenging to print on curved or irregularly shaped objects. Lastly, the printing process on tinplate can be more time-consuming and costly compared to other printing methods, as it often requires specialized equipment and inks.

- Q: Can tinplate be used for decorative purposes?

- Yes, tinplate can be used for decorative purposes as it provides a versatile and aesthetically pleasing material for various applications such as packaging, signage, and art. Its shiny surface and ability to be easily shaped and printed on make it a popular choice for creating visually appealing decorative items.

- Q: How big is the difference between tinplate and stainless steel 316L?

- 316L is a kind of austenitic stainless steel with excellent corrosion resistance. The tinplate is not comparable. 316L is superior to tinplate in appearance, corrosion resistance, heat resistance and strength. Of course, the price is much higher than that of tinplate.

- Q: How does tinplate perform in terms of light blocking?

- Tinplate is an effective material for light blocking. Its thick and durable structure prevents light from passing through, making it suitable for applications that require complete light protection, such as packaging for light-sensitive products or containers for storing food and beverages.

- Q: How does tinplate packaging contribute to product protection against odors?

- Tinplate packaging contributes to product protection against odors primarily through its excellent barrier properties. The tin layer on the surface of the packaging acts as a barrier, preventing the transfer of odors from the outside environment to the product inside. This helps to maintain the product's freshness and quality by effectively sealing off any potential odor contamination.

Send your message to us

TFS/Tin Free Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords