The Competitive Ultra-white Glass Price For Building

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass:

We manufacture a wide range of glass to meet your different demands: Float glass, Tinted glass, Stained glass, Laminated glass, Mirror glass, Aluminum mirror, Silver mirror, Reflective glass, Online coated glass, Patterned glass, Figured glass, Wired glass, Colored glass, Tempered glass, Toughened glass, Safety glass, Shower doors glass, Emulsificated glass, Acid-etched glass, Obscure glass, Sandblasted glass, Solar glass, Ultra clear low iron glass, Low-E glass, Obscure glass, Glass block, Glass brick, Picture frame in different colors and sizes.

2.Main features of Glass:

1) Standard: CCC, intertek

2) 3 - 19mm float glass

3).Size: customized sizes available

4).tempered or silk

5).drill work available

6).Printing Furniture Glass ,Beautiful surface with good coverage.

Profiled glass, as your design and requirement

Type: clear, tinted, color glazed, coated, Low-E, IGU and laminated glass etc.

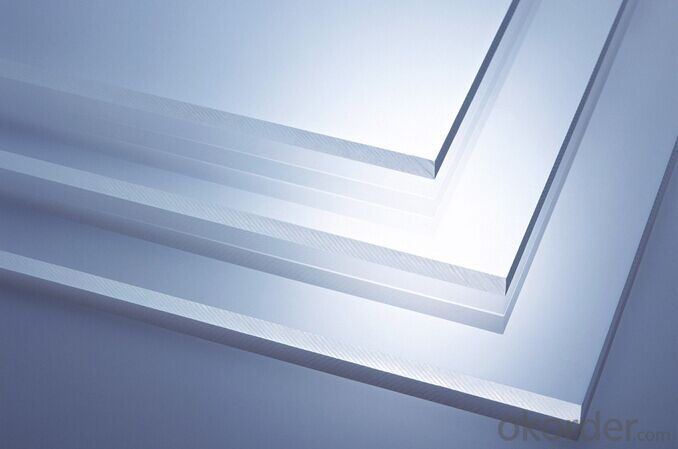

3.Glass Images:

4. Glass Technical Parameters:

CLEAR FLOAT GLASS

Thickness: 2mm-19mm

Sizes: 1524x2134mm, 1830x2440mm, 2140x3300mm, 2140x3660mm, 2250x3300mm, 3660x2140mm, 3660x2250mm etc.

EXTRA CLEAR GLASS

Thickness: 3mm-19mm

Sizes: 1830x2440mm, 2140x3300mm, 2140x3660, 2250x3300mm, 2250x3660mm etc.

TINTED GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Mist Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Ocean Blue, Pink etc.

Thickness: 3mm-12mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm, 2140x3660mm, 2250x3160mm etc.

REFLECTIVE GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Pink, Silver etc.

Thickness: 3mm-10mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm etc.

MIRROR

Types: Silver Mirror, Aluminum Mirror, Copper and Lead Free Mirror, Safety Mirror, Solar Mirror and Beveled Mirror etc.

Thickness: 1.5mm, 1.8mm, 2mm, 2.7mm, 3mm, 4mm, 5mm and 6mm etc.

Sizes: 1524x2134mm, 1830x1220mm, 1830x2440mm, 2140x3300mm, 2250x3300 etc.

LAMINATED GLASS

PVB Color: Clear, Green, Blue, Bronze, Grey, Milk white etc.

Glass Color: Clear, French Green, Dark Green, Ford Blue, Dark Blue, Bronze, Euro Grey etc. Float glass and reflective glass are available.

Thickness: 3+0.38+3mm, 4+0.38+4mm, 5+0.38+5mm, 6+0.38+6mm, 3+0.76+3mm, 4+0.76+4mm, 5+0.76+5mm, 6+0.76+6mm etc. till to 42.3mm

Sizes: 1830x2440mm, 2140x3300mm etc.

PATTERNED GLASS

Thickness: 3mm, 3.5mm, 4mm, 5mm, 6mm and 8mm

Sizes: 1220x1830mm, 1524x2134mm, 1830x2440mm, 3300x2140mm etc.

Patterns: Aqualite, Bamboo, Beehive, Chinchilla, Crystal, Diamond, Flora, Karatachi, Masterlite, Millennium, Mistlite, Morgon II, Moru, Nashiji, Rain and Wanji etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials for producing ceramics are clay (such as Suzhou soil), quartz, feldspar (potassium feldspar and albite)

- Q: Chemical materials and additives needed for the production of glass

- The production process of float glass is introduced by taking ordinary production line of daily melting capacity of 600 tons in China as an example.Float glass is made in tin bath. The length of the whole production line is about 500 meters. It can produce 550 to 600 tons of glass every day. It is equivalent to 3 meters wide, 3 millimeters thick, and the glass belt is about 25 kilometers in length. Once started, 24 hours a day is uninterrupted until the furnace is stopped for about 8-10 years. Float production is the main mode of production of flat glass

- Q: How can glass frosting be formulated? What raw materials do you use?

- Preparation of water-based environment-friendly frosting liquid, according to the A Group 8, B group of 2, the proportion with 5 copies of the preparation of tap water (25kg water frosting powder add 12.5Kg, preparation of tap water) according to the proportion of A group and B group into a plastic bucket, then according to the proportion of entering tap water (if prepared with 80 degrees above water could shorten the curing time more than half) with plastic (or bamboo sticks) stir until evenly, liquid will be prepared to cover seal, so that in the outdoor temperature under natural curing for 24 hours. The newly formulated frosting is thicker and the temperature drops. After ripening, the viscosity and temperature of the liquid can be restored to normal. When the preparation amount is large or the weather is cold, the aging time should be prolonged appropriately.

- Q: What are the paper made of? What is the glass made of? What is the plastic made of?

- The common (sodium) glass consists of a mixture of sodium silicate and calcium silicate with a small amount of silica and alumina. Usually made from a mixture of sand, sodium carbonate and calcium carbonate, and can be melted by a mixture of sodium sulphate and carbon instead of sodium carbonate.

- Q: Who has information about power plants chimneys, water glass, acid resistant concrete?

- The characteristics of water glass concrete acid: water glass acid resistant concrete with water glass as binder, sodium fluorosilicate as hardening agent, adding acid powder and acid aggregate or other additives according to a certain proportion. Features: the acid and good heat resistance, it can resist all kinds of strong oxidizing acid (such as sulfuric acid, hydrochloric acid, nitric acid) and most corrosive gases (oxygen, sulfur dioxide) erosion at high temperature (1000 DEG C) still has good acid resistance, mechanical strength and high. But this material is not resistant to hydrofluoric acid, more than 300 degrees of hot phosphoric acid and higher fatty acids or oleic acid erosion. Is a commonly used anti-corrosion material, it has a wide range of materials, acid resistance good, low cost advantages. Its disadvantages are no alkali resistance, poor impermeability and water resistance, complex construction, long maintenance period.

- Q: What's the price of 0.85mm thick plexiglass, please?

- Import plate material is better, about 900, but the price is more expensive, generally do not consider adopting, unless their own customers request, and canAt an accepted price.

- Q: What raw materials are used for glass fiber reinforced plastics? Where can I buy them?

- Glass fiber reinforced plastic is not a steel, but a composite material. Glass fiber reinforced plastic products are widely used. Most of the facilities of yachts, automobiles, water storage tanks and highways are made of glass fiber reinforced plastic products.

- Q: Is flat glass the main material or structural component in raw materials?

- In addition, the glass door glass cabinet for calculation of the force, to ensure safe and effective, can also be seen as a structural member, but it is not in the strict sense of flat glass, because has been processed, should be called glass semi-finished products or components, according to whether the main responsible carrying tasks, not to calculate the bearing capacity and determine its structure or not.

- Q: What kinds of ingredients are the glass?

- Flint glass is a high density and high refractive index glass. It can be produced by lead instead of calcium in sodium glass in molten glass. It is suitable for making optical glass and carved glass products. The coefficient of thermal expansion of hard glass is very high

- Q: Use of glass flake cement

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake could commission a heat stable layer, which can prevent the substrate cracking and spalling.

Send your message to us

The Competitive Ultra-white Glass Price For Building

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches