Raw Materials for Refractory:Tabular Alumina with Good Delivery Time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

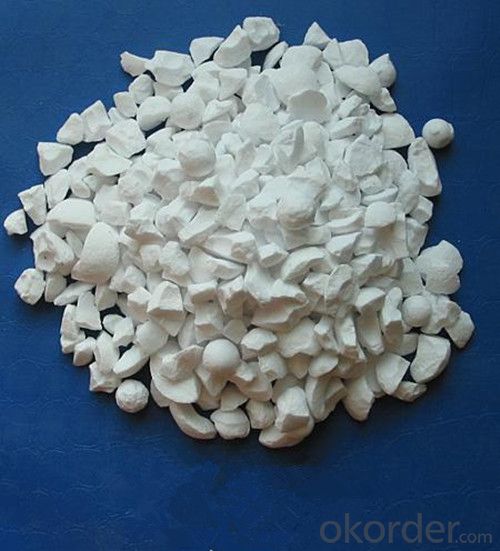

TA TABULAR ALUMINA wth GOOD DELIVERY TIME

White Tabular Alumina is pure alumina raw material, the mill, molding, drying, of 1970 degrees Celsius for ultra high temperature vertical furnace rapid heating, cooling and the formation of the density of the crystal, its microscopic phase is flake, called tabular corundum.

Product Description

| Index | FRT-Tabular Alumina T60/T64 | |||||

| Grain Size | -45 micron LI | -45 micron STD | -20 micron | |||

| AL2O3 | 99.50% | 99.50% | 99.10% | 99.30% | ||

| NA2O | 0.4% max. | 0.4% max. | 0.6% max. | 0.4% max. | ||

| SIO2 | 0.09% max. | 0.09% max. | 0.12% max. | 0.15% max. | ||

| FE2O3 | 0.02% max. | 0.02% max. | 0.3% max. | 0.02% max. | ||

| Bulk Density | 3.50G/CM3 min. | |||||

| Apparent Porocity | 5% max. | |||||

| Moisture | 1.5% max. | |||||

| Size | 0-1/1-3/-3-6mm 0-3mm, 0-2mm or as your requirements | -325mesh LI | -325mesh STD | -625mesh | ||

| Packing | 25kg per small bag, on wooden pallet with P/P cover 1MT per big jumbo sea-worthy bag or as your requirements | |||||

This product has the following advantageous chemical and physical properties:

High mechanical strength

High thermal conductivity

High resistance to thermal shock

High melting point

High electric insulation

High chemical stability

High resistance to wear

Picture:

- Q: What kinds of fireproof and fire retardant materials are there?

- recommend new Nano-insulation refractory insulation material Aerogel material, which consists of 99% pores of different sizes. it is not only the lightest and the most remarkable insualting material, but also having hydrophobic porous particles. 1830s invention.It has low thermal conductivity,not susceptibale to electrical, thermal and impact of sound with strong physical stability. It is a good insulator, but also has a strong impact resistance, three times the weight of the same volume of air. It is not heavy and can be used as heat insualting materials,buffer?materials, sound proof materials. It has attracted world attention and will be widely used in the future. Aerogel (Aerogel) features: Nontoxic to humans, insoluble in water, no burning, odorless, the world's lightest, low thermal conductivity. Aerogel heat shield is a new industrial insulation products. New products based on nanotechnology materials Aerogel, Aerogel materials in foreign countries has been widely used. We find it a lot better than the traditional insulation materials. To this end, the company introduced the product to China to open the Chinese market and import the best insualting materials to oil refining, electric power, shipbuilding, chemical, industrial pipelines, aerospace, machinery and equipment industries.

- Q: I wanna ask that magnesium oxide is refractory?

- Magnesium oxide. magnesium oxide has high refractory insulation properties. After above 1000 ℃ high temperature burning, it can be transformed into crystals. And it can be transformed into dead-burned magnesium oxide or sintered magnesia oxide until rising to above 1500 ℃. It has heat-resistant, non-conductive at room temperature and relatively poor thermal conductivity. Magnesium oxide is mainly used for the preparation of ceramic, enamel, refractory crucible and refractory bricks. I hope to help you

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- It belongs to material, and after all, more than 60% refractories are used in metallurgical industry. If you insist on classifying it, it belongs to supporting industry of metallurgical industry. Refractory industry itself is independent.

- Q: For refractory knowledge. What is the ratio of clay ramming?mass?

- Soil aggregates, dispersing agent, water reducing agent, plasticizer, binding agent and powder! ~ Bone meal feed approximately 6, OK

- Q: The classification of fire-resistant material

- Refractory material cna be divided into common and special fire proofing material. Common fire proofing material can be sub-divided in to acid fire proofing material, neutral fire proofing material. and alkaline fire proofing material according to chemical properties. Special fire proofing material can be divided into high temperature oxide refractory, refractory compounds and high temperature composite materials according to the composition. In addition, it also can be divided into common refractory products (1580 ~ 1770 ℃), high-grade refractory products (1770 ~ 1770 ℃) and super refractory products (above 2000 ℃) according to the strength . According to the shape, it can be divided into block (standard brick, special-shaped brick, etc.), special shape (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia and boron carbide, etc.) and irregular shape (refractory clay, refractory castable, ramming material and so on). According to sintering process, it can be divided into sintered product, fused cast product and melting jetting product.

- Q: What is fireproofing material? Are fireproof materials the same thing with thermal insulation materials and refractories?

- Insulation materials. Thermal insulation material is characterized by thermal insulation, which is one of the four traditional inorganic nonmetallic materials. Fire?retardant material is cahracterized by heat-resistant. Refractory is a kind of materials of resisit high temperature. Fireproof material, which is different from thermal insulation material and refractory, is a synthetic material with some fireproof subtrate added. It is essentially resistant to high temperature.

- Q: Would you like to know if there are any enterprises in Mianyang that need fire-resistant materials?

- Many enterprises need refractory materials. You can go to Mianyang large private enterprises to askSupermarkets, stations, hotels are required

- Q: Which fire-resistant materials have good viscidity?

- Viscidity is necessary for gunning mix, repair mix and bordering. It is too broad to which has good viscidity. Both gunning mix and repair mix are powder before adding water. Bordering also has little viscidity before heating. The question shoule be more specific.

- Q: Which kind of furnace hearth refractory is better?

- hearth selected material] hearth material must be durable, high temperature resistant, general selecting masnory made of refractory cement, silicon carbide refractory products, mullite or multicrystal mullite (which is the general term of minerals composed of a series of aluminum silicate, mullite is only stable binary compound in the Al2O3-SiO2 system) etc.. [hearth] is a three-dimensional space surrounded by furnace walls for combustion of the fuel. The funtion of hearth is to ensure the fuel to burn as far as possible, and to cool the gas temperature of the hearth exit to the allowed temperature of convection heating surface safe operation . Therefore, the hearth should have sufficient space and adequate heating surface. In addition, there should be reasonable shape and size in order to fit the burner and the organize aerodynamic field inside the furnace to prevent the flame from adherence, dashing walls and have high fullness and eve wall thermal load.

- Q: What are the specifications of refractory kilns ?

- Since the coefficient of thermal expansion of the basic brick is large, expansion rate is about 1-1.2% under 1000 ℃ The literature indicates that: "Under the condition that the temperature was raised to 1000 ℃ and stress in brick lining is relaxed, 300N / mm2 of compressive stress can be produced, which is equals to ten times structural strength of ordinary magnesia chrome brick, six times structural strength of magnesia chrome brick, dolomite brick and spinel brick, so any basic bricks can not afford, " the paper also pointed out that " heat expansion rate of kiln body can partially compensate for expansion rate of the inner lining of 0.2% -0.4%, which is 1/3 of thermal expansion rate of ordinary magnesia-chrome brick under 1000 ℃. However, it occurs under thermal equilibrium conditions. Thereby, the kiln should be dried slowly, allowing the temperature of the kiln body to go up slowly, thus the role of compensation can be played. " This is the key to using the basic brick. " Procedures of refractory for cement kiln "( tentative one) has clearly regulated baking and cooling of the kiln in the first section of the fifth chapters. In the heating process, in particular when the temperature is in the range of 300-1000 ℃, heating rate must be less than 60 ℃ / h. This is very clear in theory but it is difficult to implement.

Send your message to us

Raw Materials for Refractory:Tabular Alumina with Good Delivery Time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords