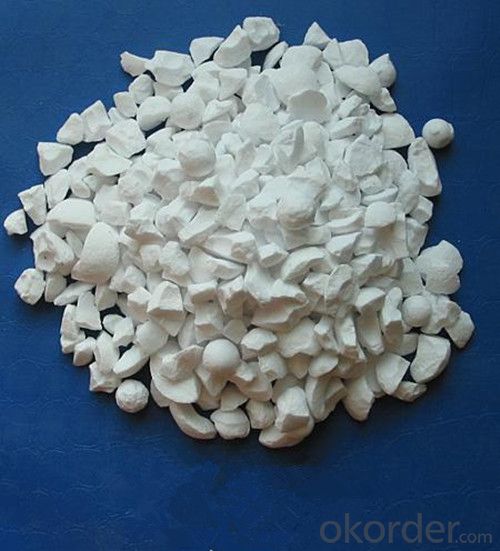

Raw Materials for Refractory:High-Quality Tabular Alumina - Good Price, Delivery Time

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

white tabular alumina

1.Al2O3>99.2%

2.Past ISO9001-2008

Description:Tabular Alumina is a pure sintered α-alumina materials that has been fully densified by rapid-sintering without the use of sintering aids at temperature in excess 1900°C.

Tabular Alumina has characteristic large, well developed hexagonal tablet shapedα-alumina crystals of up to 200µm length. applications include its use in electrical insulators, kiln furniture and as a catalyst support.

High refractoriness

Excellent thermomechanical properties

High volume stability

High density, low permeability

High thermal shock resistance

High chemical resistance

High purity

High mechanical stability

High wear-resistance

Series

Sizes, mm (mesh)

Benefit

Coarses

0-0.5mm

0-1mm ,

0-3mm0.2-0.6mm

0.5-1mm

1-2mm

1-3mm

2-5mm

3-6mm

Adds thermal shock and corrosion resistance to refractory products

Fines

0-325

Optimizes the particle size distribution and refractoriness of the refractory matrix

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are the materials of white firebricks?

- The commonly-used firebricks include alumina bricks, corundum bricks, chamotte bricks, high alumina bricks, diatomite bricks, zircon bricks, lightweight corundum bricks, zirconia bubble bricks and so on ~~~

- Q: What is the function of refractory material?

- Refractory is a basic material in the field of high temperature technology. Generally, the refractory is used as structural material or lining to resist high temperature in various thermal equipment and high temperature container. In the iron and steel industry and metallurgy industry, coke ovens are mainly composed of refractory materials. Various refractories that meet the requirements are essential in blast furnace for ironmaking, hot stove, all kinds of steel-making furnaces, soaking furnace and heating furnace. Not only the die casting for molten steel needs lots of refractory materials, but also the continuous casting needs some high-quality refractory materials. Without high-quality refractory materials, external refining is also not impossible to achieve. Statistics show that the steel industry is the sector that needs the most refractory. Pyrometallurgy and thermal processing of ferrous metal also needs refractories. All high-temperature furnaces or lining in construction materials industry or other high temperature industries that produce silicate products such as glass industry, cement industry, and ceramics industry must be constructed with refractory materials. All kinds of roasting funaces, sintering funaces, heating furnaces, boilers, flues, chimneys and protective layers in chemical, power and machinery manufacturing industry need refractories. In short, when some kind of structures, devices, equipments or vessels are used under high temperature, they all should utilize refractory to resist the high temperature because those materials will deform, soften and fuse or will be eroded, scoured or broken due to the physical, chemical, mechanical effects, which may stop the operation, affect the production, contaminate processed objects and impact the quality of products.

- Q: What kind of materials can be tested their electrical resistivity in the current refractory industry?

- fused cast bricks, fused zirconia corundum blocks, corundum, high zirconium

- Q: What does the function of SiC for refractories?

- Anti-acid corrosion anti-skinning

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

- Q: What are the main components of refractory cement?

- Refractory cement, also known as aluminate cement, can also be gray. Aluminate cement is often yellow or brown. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc.

- Q: Which kind of external wall fire barrier zone material is better?

- I recommended foam cement and particulate thermal insulation composite waterproof material, which is fire isolation area product, which uses surface of vertical?plate arranged fiber technology to make the compressive?strength in the vertical direction up to above 80KPa. At the same time, under the conditions of both exterior heat insulation and effects of humiture in the long-term, it can still maintain the non-aging performance of various aspects, and safety (reliability), fire resistance and excellent durability.

- Q: What is the particle size of boron carbide for refractories?

- 2 floor is right, support, learning! But what do you mean by boron carbide (d90=36.5, m)?

- Q: It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

Send your message to us

Raw Materials for Refractory:High-Quality Tabular Alumina - Good Price, Delivery Time

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords