Sublimation Aluminum Sheets Uk - Aluminium Hot Rolled Sheet and Alloy Aluminium Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

hot rolled aluminum coil, cold rolled aluminum sheet, cold drawn aluminum sheet, hot rolled aluminum sheet, are all widely used in the field of decoration field, etc. 1100-H14, 1050-H16, 1060-H18 are the best-selling grades, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

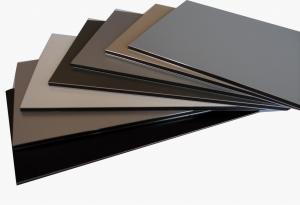

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the length range:

---It is from 2000mm to 6000mm, etc..

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding. Aluminum is a widely used material in various industries due to its lightweight, corrosion resistance, and excellent thermal conductivity. However, welding aluminum can be more challenging compared to other metals due to its high thermal conductivity and the formation of an oxide layer on its surface. Nevertheless, with the appropriate welding techniques and equipment, aluminum sheets can be successfully welded. Specialized welding processes such as Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding are commonly used for aluminum welding. These processes allow for precise control of heat input and the use of suitable shielding gases to protect the weld pool from oxidation. Additionally, proper surface preparation, cleaning, and the use of specialized aluminum welding wires or rods are essential for achieving strong and reliable welds. Overall, while welding aluminum may require specific techniques and equipment, it is definitely feasible and commonly practiced in various industries.

- Q: What are the common applications of aluminum sheets in construction?

- Aluminum sheets are commonly used in construction for a variety of applications. They are used for roofing, siding, and facades due to their lightweight nature and corrosion resistance. Aluminum sheets are also used for window frames, doors, and curtain walls. Additionally, they are utilized for insulation purposes as well as in structural components such as beams and columns.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- The aluminum oxide that forms adheres to the metal surface explains aluminum's resistance to corrosion. Aluminum naturally forms a protective oxide film, which is stable in aqueous media when the pH is between about 4.0 and 8.5. The oxide film is naturally self-renewing and accidental abrasion or other mechanical damage of the surface film is rapidly repaired. The conditions that promote corrosion of aluminum and its alloys, therefore, must be those that continuously abrade the film mechanically or promote conditions that locally degrade the protective oxide film and minimize the availability of oxygen to rebuild it.

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Think of it this way: Which metal is lighter? How do you know this? Because a given volume of gold weighs more than a given volume of aluminum. So which one has more volume? A kg of aluminum.

- Q: Are aluminum sheets easy to work with?

- Aluminum sheets, in general, prove to be easily manageable. Being a light and flexible metal, aluminum allows for easier cutting, shaping, and manipulation compared to its counterparts. It boasts the ability to be effortlessly bent, formed, and welded, granting access to a variety of fabrication methods. Furthermore, aluminum sheets exhibit excellent resistance to corrosion, which enhances their user-friendliness. Whether the goal is constructing lightweight structures, fabricating components, or crafting intricate designs, aluminum sheets offer versatility and convenience across numerous applications.

- Q: Is it possible to utilize aluminum sheets in a home renovation project?

- <p>Yes, you can use aluminum sheets for your home renovation project. Aluminum is a versatile material known for its strength, durability, and resistance to corrosion. It's commonly used for roofing, siding, and even for decorative purposes. Aluminum sheets are lightweight, easy to install, and can be painted or coated to match your home's aesthetic. They also offer good thermal performance and can be recycled, making them an environmentally friendly choice. However, it's important to consider the specific requirements of your project, such as the local climate, design preferences, and budget, to ensure aluminum is the best fit.</p>

- Q: What are the different types of patterns available for textured aluminum sheets?

- Textured aluminum sheets offer a variety of patterns, each with its own unique visual appeal and functionality. Some commonly used patterns include: 1. Diamond pattern: Also called tread plate or checker plate, this pattern features small raised diamonds on the sheet's surface. It provides excellent slip resistance, making it ideal for applications that require traction, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: Resembling a textured wall or ceiling finish, the stucco pattern has raised ridges that create a rough and bumpy surface. It is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: Mimicking the appearance of a surface hammered by hand, the hammered pattern creates a dimpled and uneven texture. It is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern is achieved by brushing the surface of the aluminum sheet with a wire brush, creating long, uniform lines. It offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the aluminum sheet's surface. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects, such as speaker grills, filters, or façades. These examples highlight the range of patterns available for textured aluminum sheets. The choice of pattern depends on the specific project requirements, including aesthetics, functionality, and durability.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Aerospace fuel tanks can indeed utilize aluminum sheets. In the aerospace industry, aluminum is widely employed because of its lightweight yet robust characteristics. Its strength-to-weight ratio is commendable, rendering it an ideal choice for fuel tanks that must endure the forces of flight while minimizing the aircraft's overall weight. Moreover, aluminum's resistance to corrosion is pivotal for aerospace fuel tanks, considering their exposure to diverse fuels and environmental conditions. Furthermore, aluminum's ease of fabrication and widespread availability make it a cost-efficient option for aerospace applications. In summary, aluminum sheets are a fitting material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: Are 101 aluminum sheets suitable for heat sinks?

- 101 aluminum sheets are not appropriate for heat sinks, as heat sinks are intended to disperse heat and therefore necessitate materials with high thermal conductivity. In comparison to other aluminum alloys often employed for heat sinks, like 6061 or 6063, 101 aluminum possesses inferior thermal conductivity. These alloys exhibit superior thermal conductivity characteristics, enabling them to effectively transfer heat away from the heat source. Consequently, it is advisable to utilize aluminum alloys that are specifically engineered for heat sinks to guarantee optimal heat dissipation and cooling performance.

Send your message to us

Sublimation Aluminum Sheets Uk - Aluminium Hot Rolled Sheet and Alloy Aluminium Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords