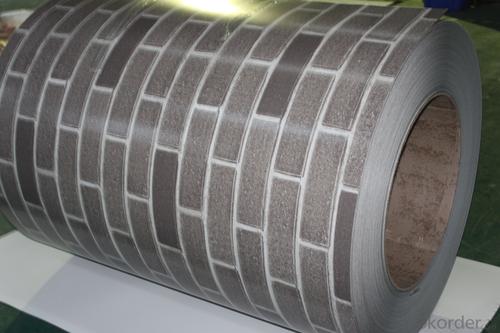

Stone Pattern Printing Steel Plate-1.00mm*1250mm Z60g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stone Pattern Printing Steel Plate-1.00mm*1250mm Z60g

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

- Q: What are the typical thicknesses of galvanized steel strips?

- The intended application and industry standards can cause the typical thicknesses of galvanized steel strips to vary. Typically, galvanized steel strips can have thicknesses ranging from 0.12 millimeters (0.0047 inches) to 3 millimeters (0.118 inches). However, the most commonly used thicknesses for galvanized steel strips usually fall between 0.5 millimeters (0.0197 inches) and 1.5 millimeters (0.0591 inches). These thicknesses strike a good balance between strength and flexibility, which makes them suitable for various uses like construction, automotive manufacturing, and appliance production. It is important to consider that specific projects and industries may have different requirements. Therefore, consulting industry standards or specifications is always advisable to determine the appropriate thickness for a particular application.

- Q: Can steel strips be used in the construction industry?

- Yes, steel strips can be used in the construction industry. They are commonly used for various purposes such as framing, reinforcement, and cladding in buildings, bridges, and other structures. Steel strips provide strength, durability, and resistance to corrosion, making them a versatile material for construction projects.

- Q: What are the main factors affecting the embrittlement of steel strips?

- The main factors affecting the embrittlement of steel strips include the presence of impurities, exposure to high temperatures, mechanical stresses, and the type of alloy used.

- Q: Is there any difference between galvanized steel strip and galvanized sheet?

- Broad sense means galvanized steel sheet.

- Q: What are the mechanical properties of steel strips?

- The mechanical properties of steel strips include high tensile strength, excellent ductility, good toughness, and high resistance to corrosion and wear.

- Q: Can steel strips be used in the renewable energy sector?

- The renewable energy sector can indeed make use of steel strips. These strips possess great versatility and can be applied in various ways within this sector. To illustrate, they find utility in constructing wind turbines, mounting solar panels, and other infrastructure projects connected to generating renewable energy. In the case of wind turbines, steel strips serve as raw materials for manufacturing turbine towers. These towers must be robust and long-lasting to endure the wind's force. Steel strips offer the required strength and stability, rendering them a perfect selection. Moreover, steel strips frequently feature in the creation of solar panel mounting systems. These systems are responsible for securing solar panels in position, guaranteeing optimal sunlight exposure. Given their strength, resistance to corrosion, and economical nature, steel strips are often employed as a structural element. Additionally, steel strips can also be employed in constructing other renewable energy infrastructure, such as hydroelectric and geothermal power plants. These plants necessitate sturdy structures and components, and steel strips can meet the demand for strength and durability. To sum up, steel strips possess a broad range of applications in the renewable energy sector. Their strength, versatility, and cost-effectiveness make them an apt choice for diverse renewable energy projects. Consequently, they contribute to the advancement and expansion of sustainable energy sources.

- Q: How are steel strips priced in the market?

- Steel strips are typically priced in the market based on several factors, including the current demand and supply dynamics, the quality and specifications of the steel strips, and prevailing market conditions. These pricing factors are influenced by the cost of raw materials, production processes, transportation, and any additional value-added services. Market competition and global steel prices also play a significant role in determining the pricing of steel strips.

- Q: Are steel strips suitable for the manufacturing of cookware?

- Yes, steel strips are suitable for the manufacturing of cookware. Steel is a durable and heat-resistant material, making it ideal for cookware that requires high temperature resistance and longevity.

- Q: What are the safety precautions to be taken while handling steel strips?

- To ensure the safety of yourself and others, it is crucial to adhere to specific safety measures when dealing with steel strips. Consider the following precautions: 1. Personal Protective Equipment (PPE): Make sure to wear appropriate PPE, including safety goggles, gloves, and steel-toed boots. These will safeguard your eyes, hands, and feet from potential injuries caused by sharp edges or flying debris. 2. Proper Lifting Technique: When lifting steel strips, always bend your knees and utilize your leg muscles instead of your back. Keep the load close to your body and avoid twisting or jerking movements to prevent strains or sprains. 3. Use Lifting Equipment: If the steel strips are heavy or bulky, employ mechanical lifting aids such as hoists or forklifts to minimize the risk of injuries. Ensure that the equipment is in good working condition and follow the correct operating procedures. 4. Secure and Stabilize the Load: When transporting steel strips, ensure that the load is securely fastened and well-balanced on the vehicle or pallet. Use straps or chains to prevent shifting or falling during transportation. 5. Be Mindful of Sharp Edges: Exercise caution when handling steel strips as they often have sharp edges that can cause cuts or punctures. Avoid dragging or sliding them against surfaces or other objects. 6. Safe Storage: When storing steel strips, organize them in a manner that prevents them from falling or toppling over. Utilize appropriate racks or shelves designed for heavy loads. 7. Maintain a Clean Work Area: Keep the work area free from clutter, debris, or any potential hazards that may result in slips, trips, or falls. Regularly sweep the floor to remove metal shavings or other sharp objects. 8. Be Aware of Hot or Cold Surfaces: Steel strips can conduct heat or cold, so handle them cautiously to avoid burns or frostbite. Use insulated gloves or other protective measures when dealing with extreme temperatures. 9. Follow Safe Cutting Procedures: When cutting steel strips, employ suitable tools and adhere to proper cutting techniques. Avoid using damaged or dull tools as they can lead to accidents. 10. Training and Supervision: Ensure that all individuals handling steel strips receive proper training in safe handling techniques and are aware of potential risks. Regularly review safety procedures and provide supervision to ensure compliance. By adhering to these safety precautions, you can minimize the likelihood of accidents or injuries while working with steel strips. Always prioritize safety and take the necessary measures to protect yourself and others in the workplace.

- Q: How are steel strips leveled or straightened?

- Steel strips are widely utilized in various industries, including automotive, construction, and manufacturing. Before further processing, it is crucial to level and straighten these strips. The process of leveling or straightening steel strips encompasses multiple techniques to ensure their flatness and accuracy. The roller leveling process stands as one of the primary methods employed for leveling steel strips. This process involves passing the steel strip through a series of rollers arranged in an alternating pattern. These rollers exert pressure on specific points of the strip, effectively stretching and bending it to eliminate any undesired curvature or waviness. The rollers are adjusted accordingly to achieve the desired levelness, and the strip is continuously fed through the rollers until the desired flatness is attained. Another commonly used method is the stretcher leveling process. In this technique, the steel strip undergoes clamping at both ends and is then stretched beyond its yield point. This stretching action allows the strip to elastically deform, effectively eliminating any residual stresses and straightening it. Subsequently, the strip is released and returns to its original length, albeit with reduced internal stresses that contribute to its flatness. Precision leveling represents an additional technique employed for leveling steel strips. This method utilizes advanced machinery equipped with multiple bending and stretching stations. The strip is fed through these stations, where controlled bending and stretching forces are applied to rectify any irregularities. The precision leveling process can achieve high levels of accuracy, ensuring the strip's flatness within narrow tolerances. Furthermore, laser leveling has emerged as a modern and technologically advanced method. Laser beams are utilized to scan the surface of the steel strip, accurately measuring its height variations. The collected data is then employed to adjust the leveling machinery, eliminating any deviations and achieving a perfectly flat strip. To summarize, various techniques, such as roller leveling, stretcher leveling, precision leveling, and laser leveling, are employed to level or straighten steel strips. These methods aim to remove undesired curvature or waviness and achieve the desired flatness, thereby ensuring the quality and usability of the steel strips in diverse industrial applications.

Send your message to us

Stone Pattern Printing Steel Plate-1.00mm*1250mm Z60g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords