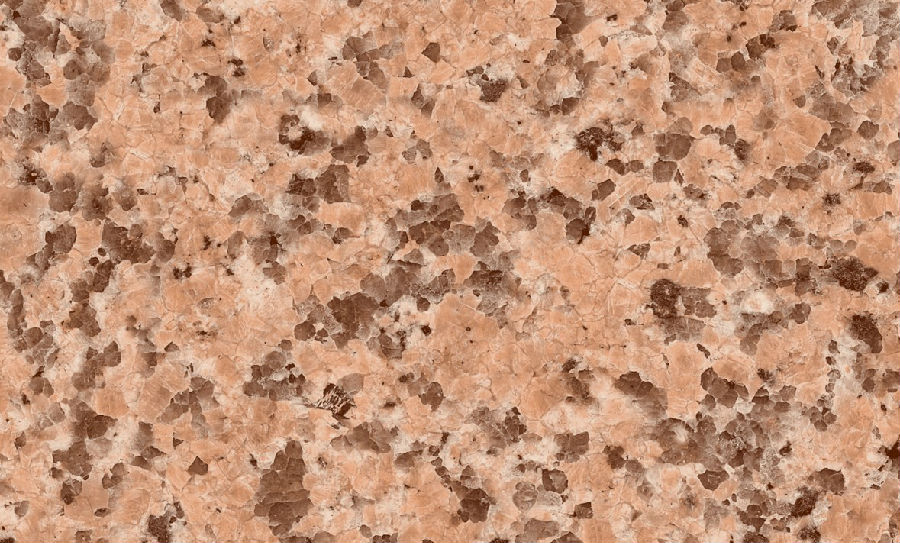

High Quality Wooden Pattern Printing Steel Plate-0.60mm*1000mm Z40g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Wooden Pattern Printing Steel Plate-0.60mm*1000mm Z40g

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

- Q: How do steel strips respond to different surface treatment processes?

- Steel strips respond differently to different surface treatment processes depending on the specific treatment method used. Some common surface treatment processes for steel strips include galvanizing, painting, electroplating, and powder coating. Galvanizing involves coating the steel strips with a layer of zinc, which provides protection against corrosion. This process is known to significantly enhance the durability and longevity of the steel strips, making them more resistant to rust and other forms of deterioration. Painting steel strips involves applying a layer of paint onto the surface, which not only enhances the aesthetic appearance but also provides a protective barrier against corrosion. The type of paint used can vary depending on the specific application and environmental conditions the steel strips will be exposed to. Electroplating is a process that involves depositing a thin layer of metal onto the steel strips through an electrochemical reaction. This can enhance the appearance, corrosion resistance, hardness, and conductivity of the steel strips, depending on the metal used for plating. Powder coating is a technique that involves applying a dry powder to the surface of the steel strips, which is then cured under heat to form a protective layer. This process provides excellent resistance against corrosion, chemicals, UV rays, and abrasion, making it a popular choice for various applications. In summary, different surface treatment processes for steel strips provide different benefits and characteristics. Galvanizing and painting offer protection against corrosion, electroplating enhances various properties, and powder coating provides excellent resistance to various environmental factors. The choice of the surface treatment process depends on the specific requirements and intended use of the steel strips.

- Q: What are the challenges faced in the production of steel strips?

- The production of steel strips presents several challenges that need to be addressed. One major challenge revolves around the high energy consumption during the manufacturing process. The production of steel demands a significant amount of energy, encompassing both electricity and fuel. This poses not only a cost challenge but also an obstacle to environmental sustainability. Another obstacle lies in ensuring the quality control of the steel strips. It is crucial to maintain consistent and uniform thickness, width, and surface quality in order to produce high-quality steel strips. Any variation in these parameters can result in defects and inconsistencies in the final product. Achieving the desired mechanical properties of the steel strips also proves to be a challenge. The production process involves various heat treatments and mechanical processing, all of which must be meticulously controlled to attain the desired strength, hardness, and ductility of the steel. Deviating from the required properties can render the steel strips unsuitable for their intended applications. Moreover, the production of steel strips often involves the handling and processing of large and heavy coils. This logistical challenge necessitates specialized equipment and infrastructure to efficiently transport, store, and handle the steel strips. Lastly, the steel industry confronts the challenge of increasing competition and market demand. In order to remain competitive, steel manufacturers must continually enhance their production processes, reduce costs, and adapt to the changing demands of customers. This entails investing in research and development, as well as embracing new technologies and market trends. In conclusion, the production of steel strips is a complex process that requires overcoming challenges related to energy consumption, quality control, mechanical properties, logistics, and market demands. Nevertheless, through continuous innovation and improvement, these challenges can be tackled, resulting in the production of high-quality steel strips that fulfill the requirements of various industries.

- Q: Can steel strips be used for making springs?

- Indeed, springs can be crafted using steel strips. The utilization of steel strips in spring production is widespread owing to their formidable strength and enduring nature. These strips can be skillfully carved into a multitude of sizes and forms, thus enabling the creation of diverse spring types like compression springs, tension springs, and torsion springs. The commendable resistance to deformation exhibited by steel strips bestows upon the springs the ability to retain their structure and functionality even when subjected to substantial burdens or repetitive usage. Moreover, through the process of heat treatment, steel strips can be further fortified, rendering them suitable for an extensive array of applications necessitating the presence of springs.

- Q: How are steel strips used in the production of telecommunications equipment?

- Steel strips are used in the production of telecommunications equipment as a structural component, providing strength and durability to the equipment. They are often used in the construction of equipment cabinets, enclosures, and racks, ensuring the stability and protection of the sensitive electronic components within.

- Q: Can cold rolled strip be plated with white zinc?

- Slight floating rust will not affect, serious rust will affect the quality of the electroplating.

- Q: Can steel strips be used in the production of building facades or cladding?

- Yes, steel strips can be used in the production of building facades or cladding. Steel strips offer durability, strength, and versatility, making them suitable for various architectural applications. They can be formed into different shapes and sizes, allowing for creative designs and customization. Additionally, steel strips can withstand harsh weather conditions, provide resistance against fire and corrosion, and have low maintenance requirements, making them a popular choice for building exteriors.

- Q: How are steel strips processed for surface leveling?

- Surface leveling of steel strips can be achieved through various methods. One commonly used technique is roller leveling, where the steel strip is fed through a set of high-pressure rollers. These rollers exert force on the strip, gradually bending it in the opposite direction of surface irregularities, effectively leveling the surface. Roller leveling can be performed as a standalone process or integrated into a continuous processing line, such as a rolling mill. Another method employed for surface leveling is tension leveling. Here, the steel strip undergoes tension forces as it passes through a series of bridle rolls positioned at different angles. These rolls stretch and elongate the strip, reducing surface irregularities and enhancing flatness. Tension leveling is particularly effective in eliminating defects like crossbow and center buckle in the steel strip. Moreover, some steel strips may undergo temper rolling, a process in which the strip is heated and rapidly cooled. This alters the metallurgical structure of the steel, improving its flatness. Temper rolling also enhances the mechanical properties of the strip, including hardness and strength. It is important to note that the specific surface leveling process employed may vary depending on the requirements of the steel strip and desired end product. Different combinations of roller leveling, tension leveling, and temper rolling can be utilized to achieve the desired surface quality, flatness, and dimensional accuracy of the steel strip.

- Q: How do steel strips contribute to reducing overall production costs in various applications?

- Steel strips contribute to reducing overall production costs in various applications in several ways. Firstly, steel strips are highly durable and have a long lifespan, reducing the need for frequent replacements and repairs. This lowers maintenance costs and downtime, resulting in increased productivity and efficiency. Additionally, steel strips can be produced in large quantities quickly, making them cost-effective for mass production. Their versatility allows them to be used in a wide range of applications, eliminating the need for different materials and reducing inventory costs. Moreover, steel strips can be recycled, reducing waste and providing a sustainable solution. Overall, the cost-effectiveness, durability, efficiency, and recyclability of steel strips make them a valuable asset in reducing overall production costs in various applications.

- Q: How are steel strips used in the production of HVAC insulation?

- Steel strips are used in the production of HVAC insulation as reinforcement or support for the insulation material. They are typically embedded within the insulation to provide strength and stability, ensuring the insulation remains intact and properly positioned within the HVAC system.

- Q: What's the difference between strip 235 and 235b?

- Q235 is Q235a, Q235 material according to the sulphur and phosphorus content from high to low is divided into ABCD four grades, grade a sulfur phosphorus was the highest relative performance (welding, plasticity) is the worst, D performance is the highest, the lowest content of parathion

Send your message to us

High Quality Wooden Pattern Printing Steel Plate-0.60mm*1000mm Z40g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords