steel pipe professional manufacturer supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | bundles |

| Delivery Detail: | 15-30 days |

| Carbon Steel Seamless Pipes | |||||||

| OD | 10mm-610mm(1/8”-24”) | ||||||

| WT | 2mm-60mm | ||||||

| Length | Random Length: 3.5m-12m, or fixed length 5.8m or as the customer’s requirement. | ||||||

| Standard | ASTM A53, ASTM A106, API 5L, DIN 17175, GOST8731/8732, G3457/G3452 etc. | ||||||

| Material | Q235B, 10#,20#,45#, 16Mn, 15MnV. | ||||||

A53B, A106B, API5L B, A192, A179C, A213-T12, A213-T22, A335-P1, A335-P2, A333 | |||||||

| ST37, ST33, ST37-2, ST35.8 ST52 etc. | |||||||

| Certificate | API certificate and ISO certificate. | ||||||

| Surface | Rust remove, black painting, antirust oil, varnish, 3PE, hot-dip galvanized etc. | ||||||

| Package | By bundles, plastic caps or steel caps, woven, wooden cases or as requirement. | ||||||

| Capability | 6000tons/month. | ||||||

| End | BE/PE. | ||||||

| Advantage | Big diameter and thick wall pipes. | ||||||

| Best price with good quality. | |||||||

| The partner you can trust. | |||||||

| Good service and very patient. | |||||||

- Q: What are the main factors affecting the formability of alloy steel billets?

- The formability of alloy steel billets, which refers to the ability of the material to be shaped or formed without cracking or fracturing, is influenced by several key factors. 1. Alloy composition: The alloy composition of steel billets plays a significant role in determining their formability. Different alloying elements such as carbon, manganese, chromium, and nickel can alter the mechanical properties of the steel, including its ductility and toughness. Higher levels of certain elements can improve formability, while excessive amounts can lead to brittleness and reduced formability. 2. Grain size and structure: The grain size and structure of the steel billets also affect formability. Fine-grained structures have better formability compared to coarser grain sizes. This is because fine grains allow for more uniform deformation and reduce the likelihood of localized strain concentration, which can lead to cracking. 3. Temperature: The temperature at which the steel billets are processed greatly influences their formability. The material's ductility and ability to deform without cracking are generally enhanced at higher temperatures. This is due to the reduction in the material's yield strength and increased plasticity. However, excessively high temperatures can also lead to excessive grain growth and decreased formability. 4. Strain rate: The rate at which the steel billets are deformed is another important factor. Higher strain rates can result in reduced formability, as the material may not have sufficient time to accommodate the deformation before fracture occurs. Controlling the strain rate during forming processes is crucial to ensure optimal formability. 5. Lubrication: The use of lubricants during the forming process can significantly improve the formability of steel billets. Lubricants reduce friction between the material and the forming tools, minimizing the risk of sticking or tearing. They also help dissipate heat generated during deformation, preventing excessive temperature rise that can negatively impact formability. 6. Forming process: The specific method used to shape the steel billets can also affect formability. Different processes, such as forging, rolling, or extrusion, impose varying levels of strain and stress on the material. Each process has its own limitations and requirements for optimal formability, and selecting the appropriate forming method is crucial to achieve the desired shape without compromising the material's integrity. In summary, the formability of alloy steel billets is influenced by their alloy composition, grain size and structure, temperature, strain rate, lubrication, and the chosen forming process. Understanding and controlling these factors are essential for achieving the desired shape and avoiding defects or failures during the forming of alloy steel billets.

- Q: How are steel billets cut and shaped into desired forms?

- Steel billets are cut and shaped into desired forms through a process called hot rolling. The billets are heated and then passed through a series of rollers, which apply pressure and shape the steel into various profiles such as bars, rods, or sheets. This process allows for precise control over the dimensions and specifications of the final product.

- Q: What are the main factors affecting the fatigue strength of stainless steel billets?

- The main factors affecting the fatigue strength of stainless steel billets include the composition and microstructure of the steel, the presence of surface defects or imperfections, the level of applied stress or load, the presence of corrosive environments, and the temperature at which the billets are operating.

- Q: What is the role of steel billets in the manufacturing of cutting tools?

- The manufacturing of cutting tools heavily relies on steel billets. These billets act as the primary material from which the cutting tool is forged or machined. Typically, steel billets are composed of high-quality steel alloys, which possess vital properties like hardness, toughness, and wear resistance that are necessary for cutting tools. To initiate the manufacturing process, the steel billets are heated to a specific temperature called the forging temperature. This temperature allows the steel to become malleable, making it easier to shape and mold into the desired cutting tool. The heated billets are then subjected to a forging process using specialized equipment, where they are struck or pressed to shape them into the desired form, such as drills, saws, or blades. Following the initial forging, the billets undergo further machining to refine their shape and dimensions. Machining processes like milling, turning, and grinding are employed to eliminate excess material, achieve precise dimensions required for the cutting tool, and create the desired cutting edge geometry. The quality of the steel billets used in the manufacturing process significantly impacts the performance and durability of the cutting tool. Steel billets with high carbon content and alloying elements like chromium, vanadium, or tungsten are often preferred as they enhance the hardness, strength, and wear resistance of the cutting tool. These properties are essential to ensure that the cutting tool can withstand the high forces, temperatures, and abrasive conditions it will encounter during use. In conclusion, steel billets serve as the foundation for manufacturing cutting tools. They provide the necessary raw material and properties required to create high-quality cutting tools that demonstrate exceptional performance, durability, and precision.

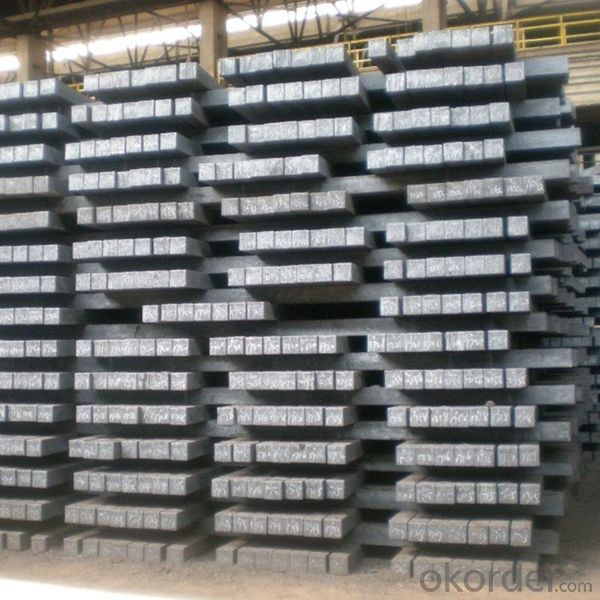

- Q: What are the applications of steel billets?

- Steel billets are primarily used as raw material in the production of various steel products such as bars, rods, wire, and seamless tubes. They are also used in the manufacturing of components for automotive, construction, and machinery industries. Additionally, steel billets can be further processed to produce forgings, which are used in heavy machinery and equipment.

- Q: Can steel billets be used in the production of utensils and cutlery?

- Utensils and cutlery can indeed be produced using steel billets. These semi-finished products have the potential to be transformed into a variety of shapes and forms, including utensils and cutlery. The remarkable properties of steel, such as its strength, durability, and resistance to corrosion, make it an ideal choice for manufacturing these items. In the production process, steel billets are often melted and cast into specific shapes. They are then further processed through techniques like forging, stamping, or machining to create the desired utensils and cutlery items. The range of final products is extensive, encompassing not only spoons, forks, and knives but also more intricate items like serving spoons, ladles, and cheese slicers. Steel utensils and cutlery are highly regarded and widely used due to their long-lasting nature and hygienic qualities.

- Q: How are steel billets used in the manufacturing of rail tracks?

- The manufacturing of rail tracks relies heavily on steel billets, which serve as a vital component. These billets, semi-finished steel pieces, are widely used as the initial material in various metalworking procedures. In the case of rail track production, the steel billets are subjected to high temperatures and subsequently passed through a sequence of rolling mills. During the rolling procedure, the steel billets gradually take shape and elongate, forming rail blooms that are characterized by their long and narrow sections. These rail blooms then undergo further processing and shaping through hot rolling, which involves passing them through multiple sets of rollers to achieve the desired dimensions and shape of the rail track. This process contributes to enhancing the mechanical properties of the steel, such as its strength and durability. Once the rail blooms have been shaped, they go through controlled cooling, a process in which they are cooled at a specific rate to optimize their microstructure and properties. This controlled cooling aids in reducing internal stresses and improving the overall quality of the rail tracks. Following the controlled cooling process, the rail blooms are subjected to straightening, cutting, and ultimately, finishing operations. These operations ensure that the rail tracks are straight, possess precise dimensions, and conform to the required standards and specifications. In conclusion, steel billets play a critical role in the manufacture of rail tracks. They are transformed into rail blooms through a series of rolling processes, and subsequently undergo further processing to produce high-quality rail tracks that are strong, durable, and capable of withstanding the heavy loads and constant use associated with railway transportation systems.

- Q: What are the different surface finishes available for steel billets?

- There are several different surface finishes available for steel billets, depending on the specific requirements and applications. Some of the commonly used surface finishes include: 1. Hot Rolled: This is the most basic surface finish obtained by rolling the steel billets at high temperatures. It results in a rough and scaled surface, which is suitable for applications where aesthetics are not a concern. 2. Cold Rolled: In this process, the steel billets are rolled at room temperature to achieve a smoother and more polished surface finish. Cold rolling helps to improve the dimensional accuracy and surface quality of the billets. 3. Pickled and Oiled: This surface finish involves the removal of scale and rust from the steel billets by using an acid solution, followed by an oil coating to prevent corrosion. It provides a clean and rust-free surface, commonly used in the automotive and construction industries. 4. Galvanized: Galvanizing involves the application of a zinc coating to the steel billets to protect them from corrosion. This surface finish provides excellent corrosion resistance, making it suitable for outdoor applications, such as fencing, roofing, and structural components. 5. Passivated: Passivation is a chemical process that removes free iron from the steel surface, enhancing its corrosion resistance. This surface finish is commonly used in the production of stainless steel billets to improve their resistance to rust and other forms of corrosion. 6. Shot Blasting: Shot blasting involves the projection of small abrasive particles onto the steel billets' surface to remove scale, rust, and other impurities. This process results in a textured and uniform surface finish, ideal for applications where improved adhesion is required, such as painting or coating. 7. Polished: Polishing is a mechanical process that involves the use of abrasive materials to smoothen the surface of steel billets and achieve a high-gloss finish. This surface finish is often used in decorative applications, such as furniture, architectural components, and jewelry. It is important to note that the choice of surface finish for steel billets depends on various factors, including the intended application, desired aesthetics, and the level of corrosion resistance required.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- The main deformation of reinforced by ribs, binding capacity larger and concrete, so it can better withstand external force. Steel is widely used in all kinds of building structure, especially for large, heavy, light and thin wall structure of high-rise building.

- Q: How are steel billets used in the manufacturing of power transmission towers?

- Power transmission towers rely on steel billets as a vital element for their construction. These towers, which provide support for electrical power lines, demand a robust and lasting material capable of withstanding the weight and stress of the overhead cables. Steel billets, essentially semi-finished steel products, serve as the raw material for fabricating power transmission towers. Typically composed of high-quality steel with exceptional strength and structural properties, these billets undergo a specific temperature heating process called forging in a furnace. Once they reach the desired temperature, the billets are transferred to a rolling mill where they are shaped and molded into the necessary sections required for power transmission towers. Employing various rolling techniques, the heated steel billets are transformed into elongated, slim sections referred to as angles, channels, or I-beams. These sections are meticulously crafted to provide the required structural strength and load-bearing capacity essential for power transmission towers. After the formation of steel sections, they undergo further processes including cutting, drilling, and welding to create the tower's components such as legs, braces, cross arms, and other reinforcements integral to the tower's structure. The steel billets utilized in the manufacturing of power transmission towers are vital in guaranteeing the towers possess the necessary strength, stability, and durability. Steel's exceptional strength-to-weight ratio makes it an ideal material for bearing the weight of cables and resisting external forces such as wind and ice loads. Furthermore, steel's resilience and durability enable it to endure harsh environmental conditions, including extreme temperatures and corrosive elements. To conclude, steel billets are an essential material in the production of power transmission towers. Through a sequence of heating, rolling, and fabrication processes, these billets are converted into various structural sections and components that comprise the towers. The use of steel ensures that power transmission towers possess the needed strength, stability, and resilience to effectively support electrical power lines.

Send your message to us

steel pipe professional manufacturer supplied by CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords