Steel Flat Bar 42CrMo, 4140, 40Cr Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar 42CrMo, 4140, 40Cr Alloy at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar 42CrMo, 4140, 40Cr Alloy are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar 42CrMo, 4140, 40Cr Alloy are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1) Specification: 10-120mm * 200-800mm, or as per customer's requirement

2) Delivery condition: EAF+LF+VD, Hot rolled, annealed, black surface, UT tested

| ASTM | USA | Ameirican Society of Mechanical Engineers |

| AISI | USA | Acronym of American Iron and Steel Institute |

| JIS | JP | Japanese Industrial Standards |

| DIN | GER | Deutsches Institut für Normung e.V. |

| UNS | USA | Unified Numbering System |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

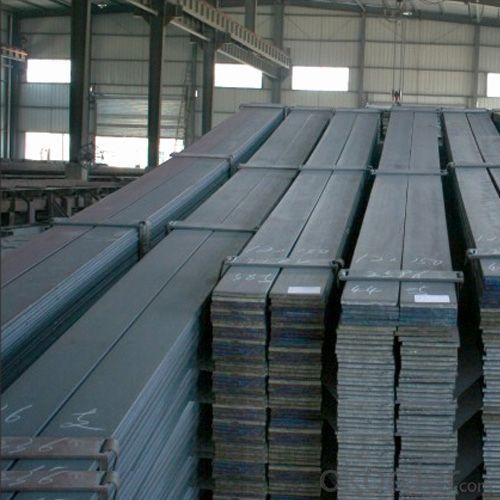

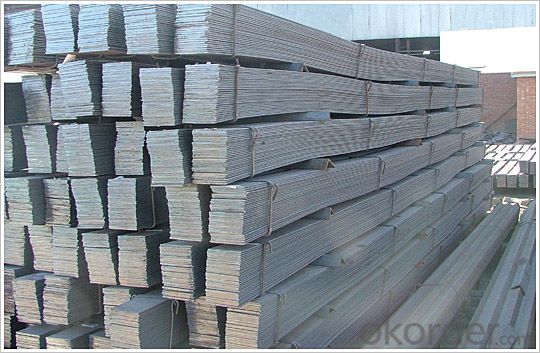

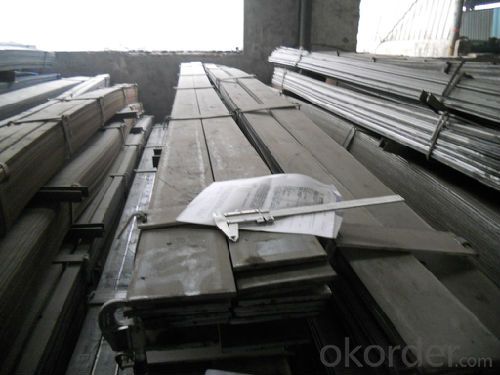

Images:

- Q: The minus sign in front of what 40 galvanized flat steel

- Also called hot galvanized and hot dip galvanizing: hot dip galvanizing is an effective way of metal corrosion, mainly used for metal structure on the facilities of the industry. The steel piece after being cleaned is dipped into the molten zinc liquid at about 500 DEG C so that the zinc coating is adhered on the surface of the steel member so as to prevent corrosion.

- Q: Are steel flat bars suitable for high-temperature applications?

- No, steel flat bars are generally not suitable for high-temperature applications. Steel has a relatively low melting point compared to other high-temperature materials such as stainless steel or refractory metals. When exposed to high temperatures, steel flat bars can experience dimensional changes, loss of strength, and even deformation or failure. For high-temperature applications, it is recommended to use materials specifically designed and engineered to withstand elevated temperatures, ensuring safety and performance.

- Q: How do steel flat bars perform in high-temperature environments?

- Steel flat bars generally perform well in high-temperature environments due to their high melting point and thermal stability. These bars can maintain their structural integrity and dimensional stability, exhibiting minimal deformation or weakening even at elevated temperatures. However, prolonged exposure to extremely high temperatures can lead to a reduction in strength and potential oxidation. Therefore, it is important to consider the specific steel grade and its intended application when assessing performance in high-temperature environments.

- Q: What are the different types of steel flat bar finishes for architectural purposes?

- There are several different types of steel flat bar finishes that are commonly used for architectural purposes. These finishes are applied to the surface of the steel flat bar to enhance its aesthetic appeal and provide protection against corrosion. One popular finish is a plain or mill finish, which refers to the raw surface of the steel without any additional treatment. This finish is often used for industrial or utilitarian applications where the appearance is not a primary concern. Another common finish is a brushed finish, also known as a satin finish. This finish is achieved by brushing the steel surface with abrasive materials, creating a textured and slightly reflective appearance. Brushed finishes are often used in modern and contemporary architectural designs. A polished finish is another option for steel flat bar. This finish involves grinding and polishing the steel surface to create a smooth and reflective appearance. Polished finishes are often used in high-end architectural projects, as they provide a luxurious and elegant look. A galvanized finish is a type of coating that is applied to the steel flat bar to protect it from corrosion. This finish involves immersing the steel in a bath of molten zinc, which forms a protective layer on the surface. Galvanized finishes are commonly used in outdoor architectural applications, such as fences, handrails, and building facades. Finally, a powder-coated finish is a type of finish that involves applying a dry powder to the steel surface and then curing it under heat. This finish provides a durable and decorative coating that is available in a wide range of colors and textures. Powder-coated finishes are often used in architectural projects where color customization is desired. In conclusion, the different types of steel flat bar finishes for architectural purposes include plain or mill finish, brushed finish, polished finish, galvanized finish, and powder-coated finish. Each of these finishes offers unique characteristics and benefits, allowing architects and designers to achieve their desired aesthetic and functional objectives.

- Q: Can steel flat bars be used for making window frames or door frames?

- Yes, steel flat bars can be used for making window frames or door frames. Steel flat bars provide strength, durability, and stability, making them suitable for such applications. They can be easily fabricated and welded to create sturdy frames that can withstand the weight and pressure of windows and doors.

- Q: Can steel flat bars be easily bent or shaped?

- Depending on their thickness and the type of steel used, steel flat bars can be easily bent or shaped. Thinner flat bars tend to be more malleable and can be bent or shaped with relative ease. On the other hand, thicker and harder steel flat bars may necessitate more force and specialized tools for bending or shaping. It is worth mentioning that the bending or shaping process may also rely on specific requirements and desired results. Professional metalworkers or fabricators often employ methods like heat treatment or cold working to attain the desired shape or bend in steel flat bars.

- Q: How do steel flat bars contribute to the overall safety of public structures?

- Public structures benefit greatly from the use of steel flat bars in various ways. Firstly, these bars possess immense strength and durability, making them an excellent choice for constructing essential components like beams, columns, and supports. This strength ensures that public structures can withstand external forces, such as heavy loads, wind, earthquakes, and other natural disasters, thereby minimizing the risk of collapse or damage. Additionally, steel flat bars exhibit remarkable resistance to fire. Unlike materials like wood or concrete, steel has a high melting point and does not combust or release toxic fumes when exposed to fire. This fire resistance capability adds an important layer of safety to public structures, enabling occupants to evacuate safely in the event of a fire emergency. Furthermore, steel flat bars display a high level of corrosion resistance, which is crucial for structures exposed to harsh weather conditions or environments with high moisture levels. Corrosion weakens materials over time and poses potential safety hazards. By utilizing steel flat bars, public structures can withstand corrosion and maintain their strength and safety for an extended period. Another advantage of steel flat bars lies in their versatility and ease of installation. Steel is a highly adaptable material that can be transformed into various shapes and sizes to meet specific design requirements. This versatility empowers engineers to create structures with intricate geometries and optimize load-bearing capacities, ensuring the overall stability and safety of public infrastructure. Lastly, steel flat bars possess excellent seismic resistance properties, making them ideal for regions prone to earthquakes. The flexibility and ductility of steel allow it to absorb and dissipate seismic energy, minimizing the impact of ground movements on the structure. This capability enhances the safety of public structures by reducing the risk of structural failure during seismic events. In conclusion, steel flat bars play a critical role in ensuring the overall safety of public structures. Their strength, fire resistance, corrosion resistance, versatility, and seismic resistance properties contribute to the durability, stability, and integrity of public infrastructure, providing a safe environment for the public to utilize and enjoy.

- Q: How do I store steel flat bars to prevent damage?

- To prevent damage to steel flat bars, it is recommended to store them in a dry and well-ventilated area, away from moisture and direct exposure to elements. You can stack them horizontally on a flat surface, ensuring they are properly supported and not overloaded. Using protective coverings, such as plastic or cardboard, between each layer can also help prevent scratches and other surface damage. Additionally, keeping them away from any corrosive materials and maintaining a consistent temperature can further protect the steel flat bars from damage.

- Q: What is the difference between hot-rolled and cold-drawn steel flat bars?

- Hot-rolled steel flat bars are made by heating a metal billet and then rolling it through a series of rollers, resulting in a flat shape. This process is known for its efficiency and cost-effectiveness, but it can result in a less precise shape and surface finish. On the other hand, cold-drawn steel flat bars are made by pulling a hot-rolled steel bar through a die at room temperature. This process improves the dimensional accuracy, surface finish, and overall strength of the steel, making it more suitable for applications that require tight tolerances and a smoother surface. Overall, the main difference between hot-rolled and cold-drawn steel flat bars lies in the manufacturing process and the resulting properties. While hot-rolled bars are more economical and widely available, cold-drawn bars offer enhanced precision and quality.

- Q: Can steel flat bars be used for creating stair treads or grating?

- Yes, steel flat bars can be used for creating stair treads or grating. Steel flat bars are commonly used in construction and industrial applications due to their strength and durability. They can be easily fabricated and welded to create stair treads or grating that provide a sturdy and safe walking surface. The flat bars can be arranged in various patterns to allow for proper drainage and airflow, making them suitable for use in outdoor areas or industrial settings. Additionally, steel flat bars can be coated or treated to enhance their resistance to corrosion, further increasing their suitability for these applications.

Send your message to us

Steel Flat Bar 42CrMo, 4140, 40Cr Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords