Melt Extract Stainless Steel Fiber - Copper Coated Steel Fiber from China NBM Company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Brand Name: cnbm

Model Number: GW-F

Material: Steel

Specifications

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

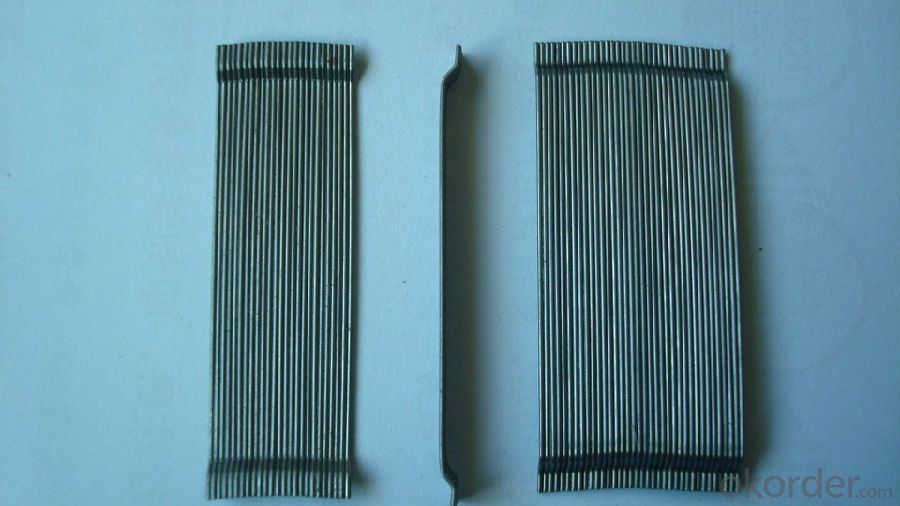

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is a steel fiber cement?

- Ordinary concrete adds steel fibers to it, which is resistant to compression, bending and tensile

- Q: What is the recommended fiber geometry for melt extract stainless steel fiber in concrete?

- The recommended fiber geometry for melt extract stainless steel fiber in concrete is typically in the form of straight, monofilament fibers. These fibers are usually slender and have a diameter ranging from 0.15 mm to 0.50 mm. The length of the fibers can vary, but it is often recommended to use fibers with lengths between 20 mm to 50 mm for optimal performance in concrete. The use of straight, monofilament fibers offers several advantages in concrete applications. Firstly, these fibers provide excellent bonding with the surrounding concrete matrix, enhancing the overall mechanical properties of the material. Secondly, the straight geometry allows for effective dispersion and distribution of the fibers throughout the concrete, ensuring uniform reinforcement and improved crack control. Additionally, the slender diameter of the fibers allows for easier mixing and placement of the concrete, without significantly affecting the workability of the mixture. It is important to note that the specific fiber geometry may vary depending on the desired performance requirements and the specific application of the concrete. Therefore, it is recommended to consult with manufacturers or experts in the field to determine the most suitable fiber geometry for a particular project.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of resilience of concrete?

- The use of melt extract stainless steel fiber in concrete increases the modulus of resilience. This means that the concrete becomes more resistant to cracking and has improved energy absorption capabilities.

- Q: Is melt extract stainless steel fiber corrosion resistant?

- Yes, melt extract stainless steel fiber is corrosion resistant. Stainless steel is known for its excellent corrosion resistance due to the presence of chromium in its composition. Chromium forms a thin protective oxide layer on the surface of the steel, which helps to prevent corrosion and rusting. This makes melt extract stainless steel fiber highly suitable for applications in harsh environments or exposure to corrosive substances. Additionally, the fiber's resistance to corrosion ensures its durability and longevity in various industries such as construction, automotive, and aerospace.

- Q: What is the effect of melt extract stainless steel fiber on the permeability of shotcrete?

- The effect of melt extract stainless steel fiber on the permeability of shotcrete is that it reduces the permeability of the material. The addition of these fibers helps to create a denser and more cohesive structure, minimizing the passage of water or other fluids through the shotcrete. This improvement in permeability can enhance the durability and performance of shotcrete in various applications, such as in underground construction or waterproofing.

- Q: How does melt extract stainless steel fiber improve the durability of sprayed concrete?

- The durability of sprayed concrete is significantly enhanced by melt extract stainless steel fiber. These fibers play a vital role in reinforcing the concrete matrix, effectively boosting its tensile strength and resistance to cracking. This is especially important in high-pressure application techniques used in sprayed concrete, as it is prone to shrinkage and cracking. Furthermore, stainless steel fibers possess unique properties, such as high corrosion resistance, which safeguard the concrete from environmental factors that can deteriorate its durability. They are highly resistant to rust and other forms of corrosion, offering particular advantages in harsh or corrosive surroundings. Additionally, the presence of these fibers improves the impact resistance of sprayed concrete. Due to their strength and flexibility, they can absorb and distribute energy when subjected to impact or dynamic loads, decreasing the risk of surface spalling or cracking. Moreover, melt extract stainless steel fibers enhance the overall cohesion and bond strength between the sprayed concrete and the substrate. This is crucial in sprayed concrete applications, ensuring a robust connection between the concrete and the applied surface, minimizing the risk of delamination or detachment. In conclusion, melt extract stainless steel fiber enhances the durability of sprayed concrete by improving its tensile strength, resistance to cracking, impact resistance, corrosion resistance, and overall bond strength. These fibers provide essential reinforcement to the concrete matrix, making it more resilient and extending its service life in a variety of challenging environments and applications.

- Q: Is melt extract stainless steel fiber suitable for use in seismic regions?

- Melt extract stainless steel fiber is well-suited for use in regions prone to earthquakes. These seismic areas necessitate materials capable of enduring the forces and movements that occur during seismic events. Melt extract stainless steel fiber possesses exceptional tensile strength and ductility, which enables it to withstand intense shaking and ground movement without cracking or breaking. Moreover, it enhances the flexural and shear strength of concrete, which is vital for maintaining the structural integrity of buildings and infrastructure in seismic regions. Additionally, stainless steel fibers are resistant to corrosion, guaranteeing long-lasting durability and performance in these locations. Consequently, melt extract stainless steel fiber is a dependable and appropriate choice for reinforcing concrete structures in seismic regions, offering added safety and stability during seismic events.

- Q: How does melt extract stainless steel fiber improve the resistance to rutting in asphalt mixtures?

- Melt extract stainless steel fiber improves the resistance to rutting in asphalt mixtures through several key mechanisms. Firstly, the addition of stainless steel fibers enhances the tensile strength and toughness of the asphalt mixture. This increased strength and toughness help to distribute the load more evenly across the pavement surface, reducing the likelihood of rutting. Secondly, the stainless steel fibers act as reinforcement within the asphalt mix, preventing the formation of cracks and reducing the propagation of existing cracks. These fibers help to maintain the integrity and stability of the asphalt pavement, preventing the development of ruts. Furthermore, the presence of stainless steel fibers in the asphalt mix enhances its resistance to deformation and deformation recovery. These fibers provide additional support and resistance to the repeated loading and heavy traffic, reducing the permanent deformation and rutting. Additionally, the stainless steel fibers also improve the resistance to moisture-induced damage in the asphalt pavement. They help to inhibit the penetration of water into the pavement, reducing the risk of moisture-related distresses such as rutting. Overall, the inclusion of melt extract stainless steel fiber in asphalt mixtures improves the resistance to rutting by enhancing the tensile strength, toughness, crack resistance, deformation resistance, and moisture resistance of the pavement. This results in a more durable and long-lasting pavement surface that can withstand heavy traffic loads without developing ruts.

- Q: How does melt extract stainless steel fiber improve the durability of concrete?

- Melt extract stainless steel fiber improves the durability of concrete by enhancing its resistance to cracking, spalling, and corrosion. The fibers act as reinforcement within the concrete matrix, increasing its tensile strength and preventing the propagation of cracks. Additionally, the stainless steel composition provides excellent resistance against corrosion, ensuring the longevity of the concrete structure.

- Q: What are the advantages of melt extract stainless steel fiber over other types of steel fibers?

- Melt extract stainless steel fibers have several advantages over other types of steel fibers. Firstly, they exhibit superior corrosion resistance, making them ideal for applications in harsh environments or where exposure to moisture is a concern. Additionally, melt extract stainless steel fibers offer exceptional temperature resistance, ensuring their stability and performance even at high temperatures. Moreover, these fibers possess excellent mechanical properties, such as high tensile strength and good ductility, which enhance their durability and ability to withstand heavy loads. Lastly, melt extract stainless steel fibers have a higher aspect ratio, meaning they have a longer length relative to their diameter, resulting in improved bonding with concrete and enhanced reinforcement properties. Overall, these advantages make melt extract stainless steel fibers a preferred choice for various applications in construction, infrastructure, and industrial sectors.

Send your message to us

Melt Extract Stainless Steel Fiber - Copper Coated Steel Fiber from China NBM Company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords