Melt Extract Stainless Steel Fiber - Steel Fiber Copper Coated from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

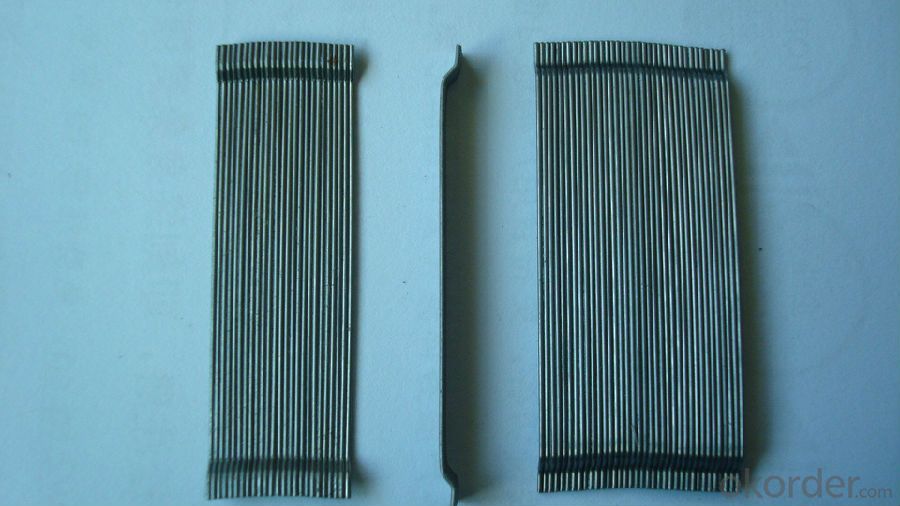

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the dimensional stability of concrete?

- The dimensional stability of concrete is significantly affected by the incorporation of melt extract stainless steel fiber. These fibers are introduced into the concrete mixture during the mixing process, ensuring their even distribution throughout the material. One of the primary advantages of melt extract stainless steel fiber lies in its capacity to enhance the overall strength and durability of concrete. Acting as reinforcement, these fibers provide additional tensile strength to the material, effectively preventing cracking and shrinkage, which are common problems in concrete structures. By mitigating cracking and shrinkage, melt extract stainless steel fiber betters the dimensional stability of concrete. As a result, the material retains its original shape and size over time, even when subjected to fluctuating environmental conditions such as temperature variations or exposure to moisture. In addition, the inclusion of these fibers improves the overall performance of concrete in terms of impact resistance, abrasion resistance, and fatigue resistance. Consequently, it proves particularly advantageous in applications where the concrete will experience heavy loads or frequent wear and tear. Moreover, melt extract stainless steel fiber can also augment the fire resistance of concrete. Due to their high melting point, these fibers impede the rapid spread of fire and the subsequent structural collapse. This attribute is particularly crucial in buildings and structures where fire safety is a paramount concern. Overall, the utilization of melt extract stainless steel fiber in concrete significantly enhances its dimensional stability, strength, and durability. Consequently, it results in the creation of longer-lasting and more reliable concrete structures that can effectively withstand various environmental and mechanical forces.

- Q: How does melt extract stainless steel fiber improve the impact resistance of bridge decks?

- The use of melt extract stainless steel fiber in bridge deck construction shows great promise in enhancing impact resistance. This material is produced by melting stainless steel and extracting it into fibers of varying lengths and diameters. These fibers are then incorporated into the concrete matrix during the construction process. The inclusion of melt extract stainless steel fiber in bridge decks offers numerous benefits that bolster their impact resistance. Firstly, the fibers serve as reinforcement within the concrete, establishing a three-dimensional network that boosts tensile strength and overall durability. This reinforcement effectively distributes load and impact forces, preventing the propagation of cracks and fractures that could compromise the integrity of the bridge deck. Furthermore, the distinctive properties of stainless steel, such as its high strength, corrosion resistance, and ductility, make it an ideal material for enhancing impact resistance in bridge decks. When subjected to impact or dynamic loading, the stainless steel fibers absorb and dissipate energy throughout the concrete matrix. This reduces stress concentration and minimizes the risk of damage. The energy absorption mechanism enables bridge decks to withstand heavy traffic, seismic events, and other external impacts. In addition, melt extract stainless steel fibers improve crack resistance in bridge decks. These fibers act as micro-reinforcements, inhibiting the formation and expansion of cracks. They bridge small cracks and prevent them from growing larger. This crack bridging effect not only enhances the overall durability of the bridge deck but also reduces the need for maintenance and extends the structure's service life. In conclusion, the use of melt extract stainless steel fiber in bridge deck construction is highly beneficial, greatly enhancing impact resistance. Through reinforcement of the concrete matrix, energy absorption and dissipation, and improved crack resistance, this material ensures the longevity and structural integrity of bridge decks, making them more resilient to a wide range of impacts.

- Q: Is melt extract stainless steel fiber compatible with various types of admixtures?

- Various types of admixtures can be used with melt extract stainless steel fiber, making it compatible. The versatility and compatibility of stainless steel fibers with different concrete admixtures are well known. This compatibility is a result of stainless steel's chemical properties, which provide resistance to corrosion and chemical degradation. By adding melt extract stainless steel fibers to concrete, the mechanical properties of the material are enhanced. This includes increased flexural and tensile strength, improved impact resistance, and reduced cracking. These fibers also contribute to the overall durability and longevity of the concrete. Melt extract stainless steel fibers can be utilized alongside various admixtures, such as superplasticizers, air-entraining agents, and water reducers. These admixtures are commonly employed to improve the workability, strength, and durability of concrete. The compatibility of stainless steel fibers with these admixtures allows for the customization and optimization of concrete mixes to meet specific project requirements. In conclusion, melt extract stainless steel fibers harmonize well with different types of admixtures and can be successfully incorporated into concrete mixes to enhance performance and durability.

- Q: Does melt extract stainless steel fiber increase the resistance to cracking in concrete?

- Yes, melt extract stainless steel fiber does increase the resistance to cracking in concrete. Stainless steel fibers are commonly added to concrete mixes as reinforcement to improve its tensile strength and prevent cracking. The addition of these fibers helps to distribute stress and reduce shrinkage, thus increasing the overall resistance to cracking in the concrete. Melt extract stainless steel fibers are particularly effective in enhancing the concrete's resistance to cracking due to their high tensile strength, durability, and superior bonding properties.

- Q: How does melt extract stainless steel fiber prevent cracking in concrete?

- Melt extract stainless steel fiber prevents cracking in concrete by improving its tensile strength and ductility. The fibers act as reinforcement, dispersing the stress throughout the concrete mixture and reducing the formation and propagation of cracks. This helps in enhancing the overall durability and structural integrity of the concrete.

- Q: Can melt extract stainless steel fiber be used in concrete pipes and culverts?

- Concrete pipes and culverts can benefit from the use of melt extract stainless steel fiber. These fibers are often added to concrete mixes to enhance their mechanical properties, such as increasing tensile strength, ductility, and durability. Given that concrete pipes and culverts are exposed to various loadings and environmental conditions, including high pressure, chemical exposure, and freeze-thaw cycles, incorporating melt extract stainless steel fibers into the mix can greatly improve the overall performance and longevity of these structures. The stainless steel fibers act as reinforcement, preventing crack propagation and enhancing the concrete's resistance to cracking and spalling. Additionally, they also provide corrosion resistance, which proves advantageous in environments with high moisture or chemical exposure.

- Q: Can melt extract stainless steel fiber be used in nuclear power plant construction?

- Yes, melt extract stainless steel fiber can be used in nuclear power plant construction. Stainless steel fibers are commonly used in construction projects for their high strength, corrosion resistance, and thermal stability. These qualities make them suitable for various applications in nuclear power plants, such as reinforcing concrete structures, improving the mechanical properties of concrete, and enhancing the overall durability of the plant. Additionally, stainless steel fibers can withstand high temperatures and radiation exposure, which are important considerations in nuclear power plant environments. Therefore, melt extract stainless steel fibers can be a valuable material for ensuring the safety and longevity of nuclear power plant construction.

- Q: How does melt extract stainless steel fiber improve the resistance to chemical attack in concrete?

- Melt extract stainless steel fiber is known for enhancing the resistance to chemical attack in concrete due to its unique properties and characteristics. When added to concrete mixtures, the stainless steel fibers act as a reinforcement that improves the durability and longevity of the concrete structure. One of the primary ways in which melt extract stainless steel fiber improves the resistance to chemical attack is by forming a physical barrier against corrosive substances. Concrete is generally susceptible to chemical attack from substances such as acids, alkalis, and chlorides, which can penetrate the concrete matrix and cause deterioration over time. However, the addition of stainless steel fibers creates a network of reinforcement within the concrete, which acts as a protective barrier against chemical intrusion. This, in turn, reduces the permeability of the concrete and prevents the corrosive substances from reaching and damaging the underlying steel reinforcement. Furthermore, melt extract stainless steel fiber also enhances the resistance to chemical attack by improving the mechanical properties of the concrete. The addition of stainless steel fibers increases the flexural strength, tensile strength, and impact resistance of the concrete, making it more resistant to cracking and spalling caused by chemical exposure. This improved mechanical performance helps to maintain the integrity of the concrete structure and prevents the ingress of corrosive substances through cracks and fissures. Moreover, stainless steel fibers also play a crucial role in minimizing the effects of chemical attack by reducing the formation of microcracks in the concrete. Chemical attack can lead to the formation of cracks and fractures in the concrete, which can further accelerate the deterioration process. However, the presence of stainless steel fibers helps to distribute the stress and load more evenly throughout the concrete, preventing the concentration of forces that can lead to crack formation. By minimizing the formation of microcracks, the stainless steel fibers effectively reduce the vulnerability of the concrete to chemical attack and enhance its overall durability. In conclusion, melt extract stainless steel fiber improves the resistance to chemical attack in concrete by forming a physical barrier against corrosive substances, enhancing the mechanical properties of the concrete, and minimizing the formation of microcracks. These combined effects result in a more durable and long-lasting concrete structure that is better able to withstand the detrimental effects of chemical exposure.

- Q: What is the effect of melt extract stainless steel fiber on the durability of concrete?

- The use of melt extract stainless steel fiber in concrete significantly improves its durability. The fibers act as reinforcement, enhancing the strength and resistance of the concrete to cracking, shrinkage, and impact. This results in a longer lifespan for the concrete structure, reducing the need for repairs or replacement. Additionally, the stainless steel fibers increase the concrete's resistance to corrosion, making it suitable for various environmental conditions. Overall, the inclusion of melt extract stainless steel fiber positively impacts the durability and performance of concrete.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymers (FRP)?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymers (FRP). Stainless steel fibers are commonly used in FRP composites to enhance their mechanical properties such as strength, stiffness, and toughness. These fibers are typically added to the polymer matrix during the manufacturing process to improve the overall performance of the composite material. The melt extract stainless steel fibers have excellent corrosion resistance, high tensile strength, and good thermal stability, making them suitable for use in FRP applications where durability and reliability are important. Additionally, the presence of stainless steel fibers can also provide electromagnetic shielding properties to the FRP composites, making them suitable for certain applications such as in the aerospace or automotive industries. Overall, melt extract stainless steel fibers can be effectively used in fiber-reinforced polymers to enhance their mechanical and functional properties.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Copper Coated from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords